We all know that the acronym API stands for the American Petroleum Institute. So, obviously, API flanges are flanges manufactured following the guidelines specified in API 6A specification. ASME B16.5 provides guidelines for flanges used in normal piping and pipeline systems, whereas API flanges are mainly used for wellhead and Christmas tree equipment. The pressure rating classes for ASME and API flanges are quite different. In this article, we will explore API flanges in detail.

Pressure Ratings for API Flanges

API 6A flanges have the following six pressure ratings:

- 2000 psi (13.8 MPa)

- 3000 psi (20.7 MPa)

- 5000 psi (34.5 MPa)

- 10,000 psi (69.0 MPa)

- 15,000 psi (103.5 MPa), and

- 20,000 psi (138.0 MPa)

As you can see the pressure ratings are completely different from the ASME B16.5 flanges (or ASME B16.47 flanges) which have pressure classes 150, 300, 600, 900, 1500, 2500, etc.

Types of API Flanges

There are three types of API flanges as defined in API 6A. They are:

- API 6A Type 6B

- API 6A Type 6BX, and

- Segmented API flanges.

Out of these, API 6B and 6BX flanges are quite common and used widely. Based on the pressure rating they have sub-classes as mentioned below:

- API 6B-2000 psi flanges

- API 6B-3000 psi flanges

- API 6B-5000 psi flanges

- API 6BX-2000 psi flanges

- API 6BX-3000 psi flanges

- API 6BX-5000 psi flanges

- API 6BX-10000 psi flanges

- API 6BX-15000 psi flanges, and

- API 6BX-20000 psi flanges

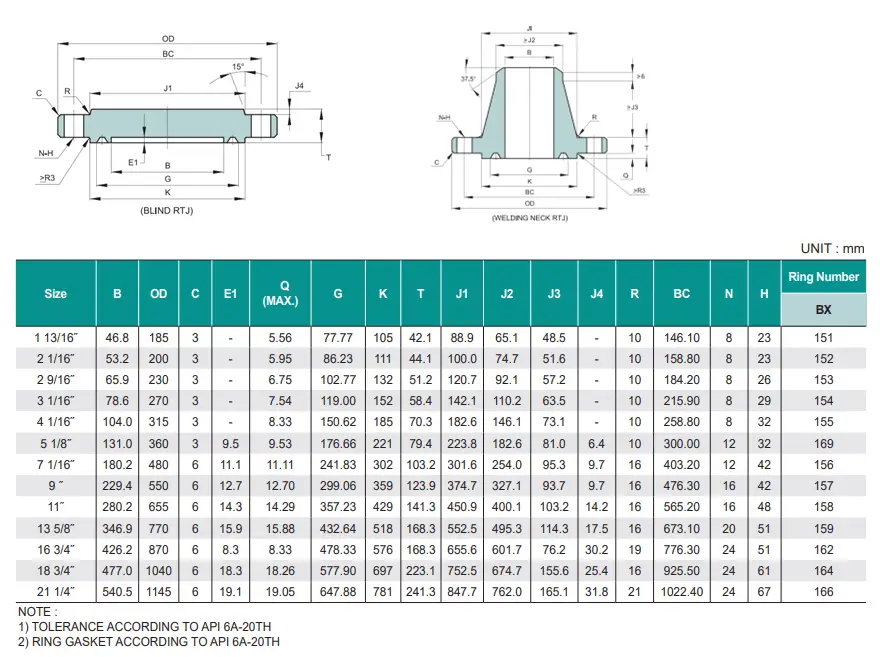

Types 6B and 6BX flanges may be used as integral, blind, or weld-neck flanges. Each of the above types of API flanges has its own size and rating limitations. Type 6B may be used as threaded flanges but Type BX flanges are not used for threaded applications.

Differences Between API and ASME Flanges | API vs ASME Flanges

The biggest difference between API and ASME flanges is that the API flanges can handle much higher operating pressure as compared to the ASME flanges. Due to higher working pressure, API flanges have higher strength and thicknesses to handle that high pressure. API flanges are typically found in heavy oil refinery systems, bitumen upgraders, Christmas tree applications, wellheads, nuclear power applications, and other petrochemicals and acids.

API flanges are designed for resisting corrosion, pitting, and cracking due to the stress because of the caustic solutions they are exposed to. API flanges are a very good choice for refineries that handle substances such as oil and explosive gases, that operate under very high pressure and temperature tolerances.

ASME flanges are used for common applications like handling water, steam, air, and gas for industrial processes.

Similarities Between API and ASME Flanges

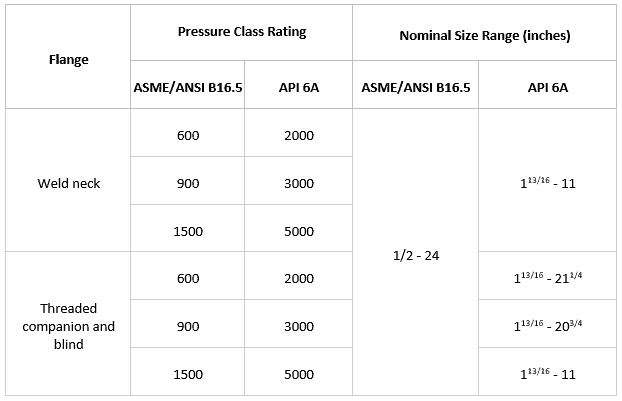

Some of the API and ASME flanges have the same bolt circle diameter and bolt holes. So, some API flanges can easily be joined with ASME flanges even though the flange rating is different. The flanges as per API 6A and ASME/ANSI B16.5 which share similar dimensions are listed in the below-attached image:

API Flange Dimension Charts

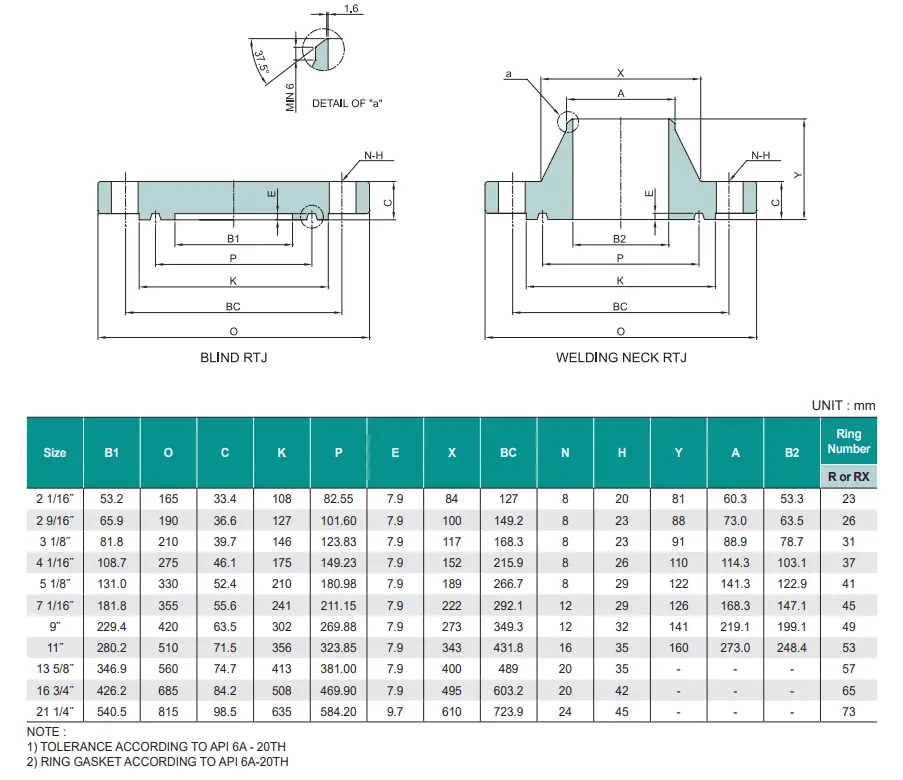

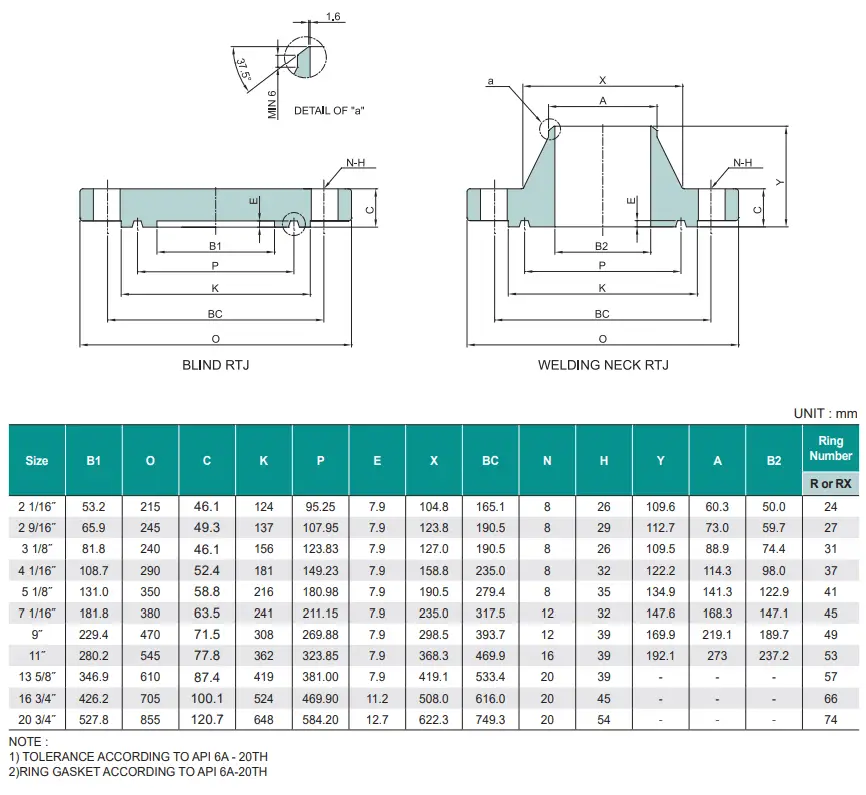

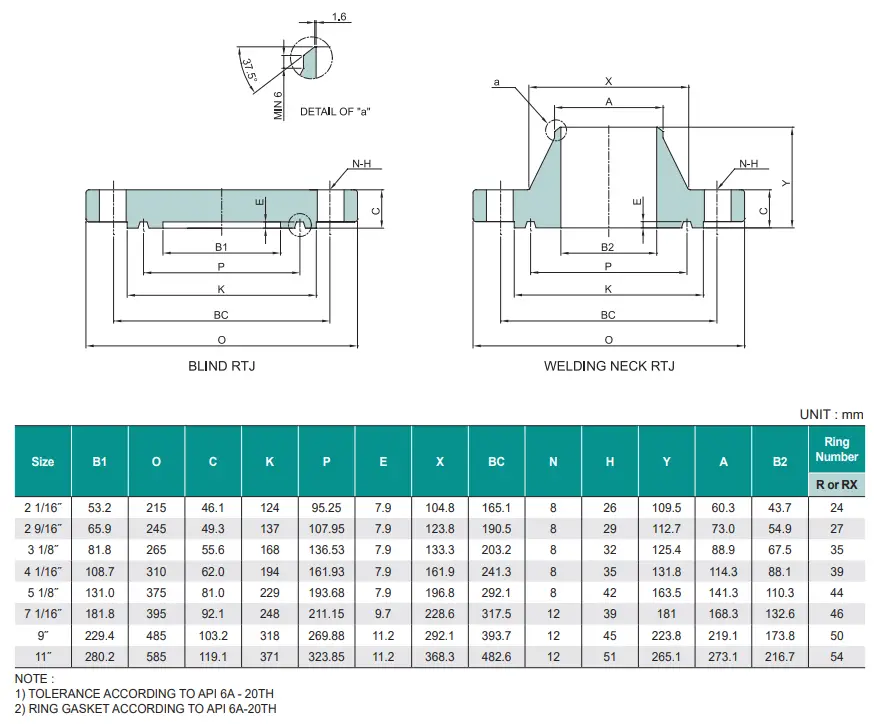

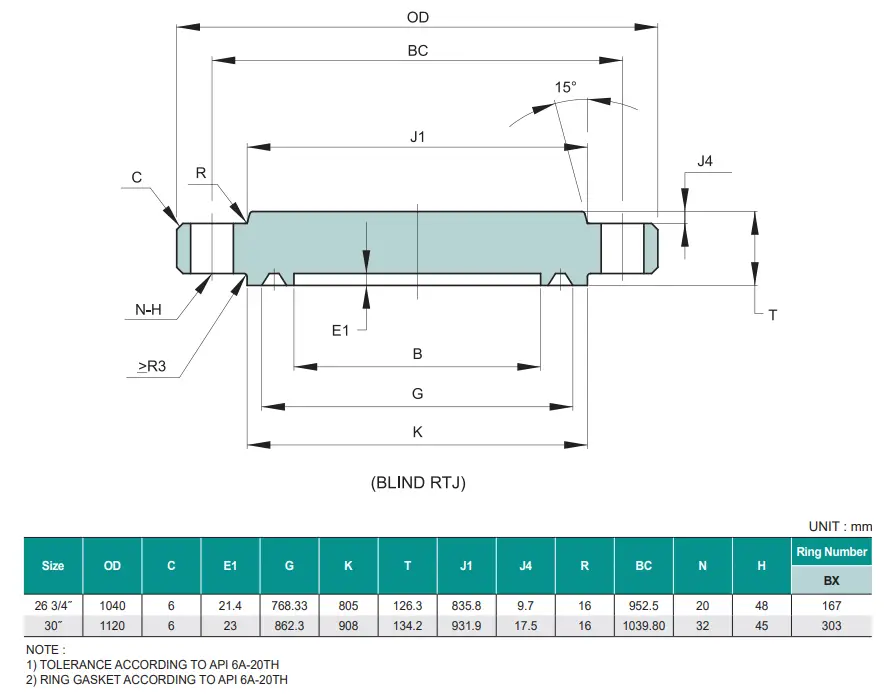

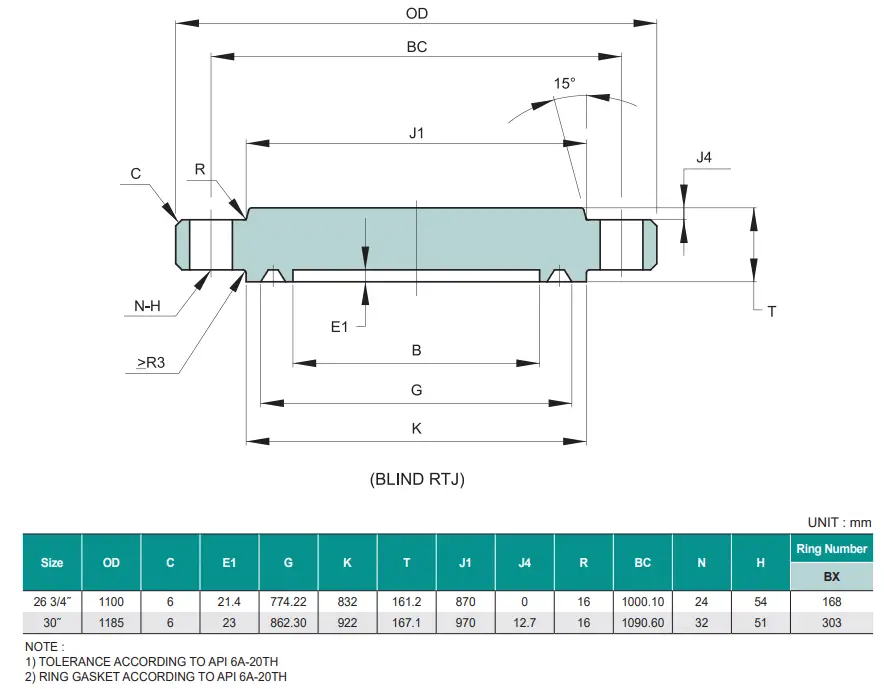

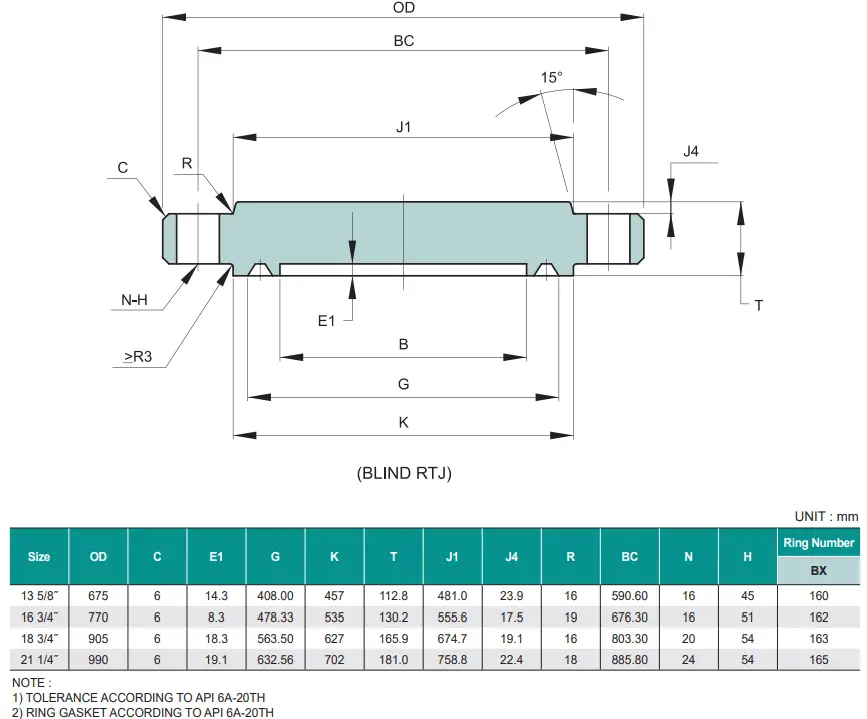

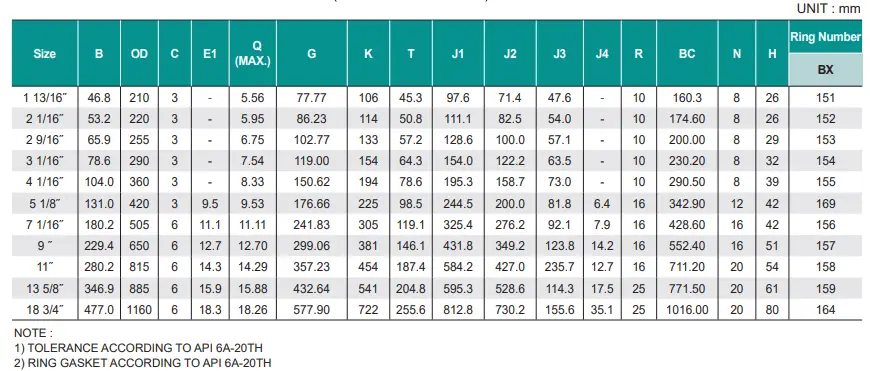

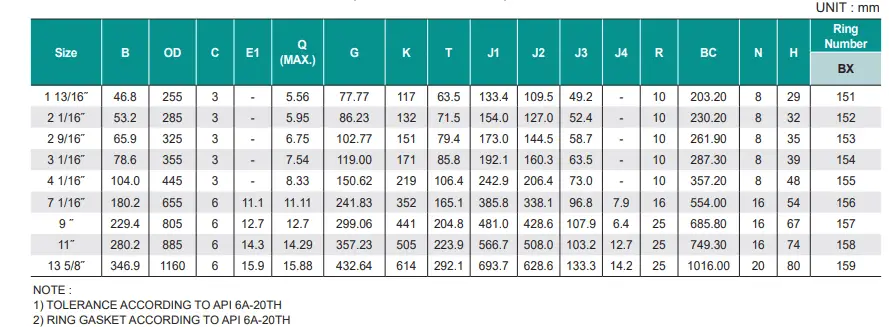

The dimension chart of the most common API flanges is provided below:

Dimensional Chart for API Flange Type 6B -2000 psi (13.8 MPa)

Dimensional Chart for API Flange Type 6B -3000 psi (20.7 MPa)

Dimensional Chart for API Flange Type 6B -5000 psi (34.5 MPa)

Dimensional Chart for API Flange Type 6BX -2000 psi (13.8 MPa)

Dimensional Chart for API Flange Type 6BX -3000 psi (20.7 MPa)

Dimensional Chart for API Flange Type 6BX -5000 psi (34.5 MPa)

Dimensional Chart for API Flange Type 6BX -10000 psi (69.0 MPa)

Dimensional Chart for API Flange Type 6BX -15000 psi (103.5 MPa)

Dimensional Chart for API Flange Type 6BX -20000 psi (138.0 MPa)

Image Credit for the images from Fig. 2 to Fig. 10 is https://www.stnhcorp.com/.

API Flange Leakage Checking

Flange leakage checking for API flanges is quite easy. From the stress analysis software, we have to find out the calculated axial force and bending moment at the flange face. Then enter the required curve based on size and bolt makeup stress provided in the API TR 6AF standard. Based on the bending moment and bore pressure draw your curve on those charts to find out the allowable axial load (tension). If the calculated axial force is less than the allowed tension as per the curve, then the API flange is considered to be safe.

Other API Flange Standards

There are some other API flange standards that provide guidelines for API flanges. They are:

- API 605: API 605 provides the standard dimensions and pressure ratings for large-diameter carbon steel flanges (NPS 26″ and larger)

- API 17D: API 17D specifies subsea wellhead and tree equipment, including flanges, used in offshore drilling and production operations.

API flanges are essential components in the oil and gas industry, providing a reliable and standardized method for connecting pipes, valves, and equipment. Understanding the different types, materials, dimensions, and installation procedures associated with API flanges is crucial for ensuring safe and efficient operations. By adhering to API standards and following proper installation practices, users can benefit from reliable connections, minimal leakage, and enhanced system performance in their oil and gas applications.

Thank you Engr. Anup. I was trying to find out the difference between API 6A flanges 6B & 6BX and your above information has helped a lot.

Hi Anup,

I am working as a design engineer in the oil and gas industry. I am inquisitive to know if there is any method to calculate the Welding neck flange schedule of the API 6A – 6BX standard.

Please help me if you have any idea about it.

Thanks

Hi Anup, I am Abhijit Pal, based in Dubai, recently arrived. I am associated with a flange manufacturing company. My past experience is with Petrofac, CCIC all EPC companies and last 15 years with Cairn India an Oil and Gas operative company in India.

I need some help from you regarding how to qualify in API for flange manufacturing we have.

Thanks,

Abhijit

Hi Engr. Anup, thank you very much for the sharing. It helped a lot.