When it comes to piping design and construction in industrial settings, the American Society of Mechanical Engineers (ASME) plays a crucial role in establishing safety and performance standards. Two of the most referenced codes within the ASME B31 series are ASME B31.3 and ASME B31.1. While both codes govern piping systems, they cater to different industries and applications. In this article, we’ll delve into the key differences between ASME B31.3 and ASME B31.1

What is the ASME B31.3, or Process Piping Code?

ASME B31.3, or Process Piping Code, provides rules for piping design for petroleum refineries; onshore and offshore petroleum and natural gas production facilities; chemical, pharmaceutical, textile, paper, ore processing, semiconductor, and cryogenic plants; food and beverage processing facilities; and related processing plants and terminals. This code is known as the Bible for Process Piping Professionals. So this code dictates the design considerations of process plants.

ASME B31.3 covers a wide range of fluid services, including liquids, gases, and vapors that are often transported at high pressures and temperatures.

What is ASME B31.1, or Power Piping Code?

ASME B31.1, or Power Piping Code, provides rules for piping typically found in electric power generating stations, industrial and institutional plants, geothermal heating systems, and central and district heating and cooling systems. This code is very important for power piping professionals, as this code governs the design rules for power generation plants.

ASME B31.1 is tailored for piping systems that are used in power generation and industrial plants, particularly those involving steam and other high-energy fluids.

Difference Between ASME B31.3 and ASME B31.1 (B31.1 vs B31.3)

During piping stress analysis of a piping system, it sometimes seems that there is no major difference between ASME B31.3 and ASME B31.1. Simply changing the codes in the input spreadsheet is sufficient for analysis. But if we take a closer look at both B31.3 and B31.1, we can understand that there are some major differences in the rules, applications, and guideline considerations between ASME B31.1 and ASME B31.3. In this article, we have listed 18 major differences between the process piping (B31.3) and the power piping (B31.1) code.

From the above discussions, it is clear that both ASME B31.3 and ASME B31.1 codes, i.e., Process Piping Code and Power Piping Code, are different. Both are related to piping design aspects but vary widely in design considerations. The following table lists the major differences between ASME B31.3 and ASME B31.1.

| Sr. No | Parameter | ASME B31.3-Process Piping | ASME B31.1-Power Piping |

| 1 | Scope (B31.3 vs B31.1) | ASME B31.3 provides rules for Process or Chemical Plant piping. | ASME B 31.1 provides rules for Power Plant piping. |

| 2 | Basic Allowable Material Stress | As per ASME B31.3, the basic allowable material stress value is higher (For example the allowable stress value for A 106 B material at 250 Deg C is 132117.328 Kpa as per ASME B 31.3) than the same as per B31.1. | The basic allowable material stress value as per ASME B31.1 is lower (For example the allowable stress value for A 106 B material at 250 Deg C is 117900.344 Kpa as per ASME B 31.1) than that of ASME B31.3. |

| 3 | Allowable Sagging (Sustained) | ASME B31.3 code does not specifically say about any limit of allowable sagging. An allowable sagging of up to 15 mm is acceptable in general. B31.3 does not provide a suggested support span. | ASME B31.1 clearly specifies the allowable sagging value as 2.5 mm. Table 121.5-1 of ASME B 31.1 provides a suggested support span. |

| 4 | SIF on Reducers | Process Piping Code ASME B31.3 does not use SIF (SIF=1.0) for reducer stress calculation | Power Piping code ASME B31.1 uses a maximum SIF of 2.0 for reducers while pipe stress calculation. |

| 5 | Factor of Safety | ASME B31.3 uses a factor of safety of 3; relatively lower than ASME B31.1. | ASME B31.1 uses a safety factor of 4 to have higher reliability as compared to Process plants |

| 6 | SIF for Butt Welded Joints | B31.3 uses a SIF of 1.0 for butt-welded joints | B31.1 uses a SIF of up to 1.9 max in stress calculation. |

| 7 | Approach towards SIF | ASME B31.3 uses a complex in-plane, out-of-plane SIF approach. | ASME B31.1 uses a simplified single SIF Approach. |

| 8 | Maximum values of Sc and Sh | As per the Process Piping code ASME B31.3, the maximum value of Sc and Sh are limited to 138 Mpa or 20 ksi. | For the Power piping code (ASME B31.1), the maximum value of Sc and Sh are 138 Mpa only if the minimum tensile strength of the material is 70 ksi (480 Mpa) otherwise it is dependent on the values provided in the mandatory Appendix A as per temperature. |

| 9 | Allowable Stress for Occasional Stresses | The allowable value of occasional stress as per ASME B31.3 is 1.33 times Sh | As per ASME B31.1, the allowable value of occasional stress is 1.15 to 1.20 times Sh |

| 10 | Equation for Pipe Wall Thickness Calculation | The equation for pipe wall thickness calculation in B31.3 is valid for t<D/6. | There is no such limitation in the Power Piping (ASME B31.1) wall thickness calculation. However, they add a limitation on maximum design pressure. |

| 11 | Section Modulus, Z for Sustained and Occasional Stresses | While Sustained and Occasional stress calculation, the Process Piping code ASME B31.3 reduces the thickness by corrosion and other allowances. | ASME B31.1 calculates the section modulus using nominal thickness. Thickness is not reduced by corrosion and other allowances. |

| 12 | Rules for material usage below -29 Deg. C | B31.3 provides extensive rules for the use of materials below -29 °C | The power piping code, B31.1, does not provide any such rules for pipe materials below -29 deg C. |

| 13 | Maximum Value of Cyclic Stress Range Factor | The maximum value of cyclic stress range factor, f as per B31.3 is 1.2. | As per ASME B31.1, the maximum value of f is 1.0 |

| 14 | Allowance for Pressure Temperature Variation | As per clause 302.2.4 of ASME B31.3, occasional pressure-temperature variation can exceed the allowable by (a) 33% for no more than 10 hours at any one time and no more than 100 hours/year or (b) 20% for no more than 50 hours at any one time and no more than 500 hours/year. | As per clause 102.2.4 of ASME B31.1, occasional pressure-temperature variation can exceed the allowable by (a) 15% if the event duration occurs for no more than 8 hours at any one time and not more than 800 hours/year, or (b) 20% if the event duration occurs for not more than 1 hour at any one time and not more than 80 hours/year |

| 15 | Design Life | Process Piping following ASME B31.3 is normally designed for 20 to 30 years of service life. | Power Piping using ASME B31.1 is generally designed for 40 years or more of service life. |

| 16 | PSV reaction force | B31.3 code does not provide specific equations for PSV reaction force calculation. | ASME B31.1 provides specific equations for PSV reaction force calculation. |

| 17 | Hydrostatic Test Pressure | As per ASME B31.3, the hydrostatic test for the piping system needs to be performed at 1.5 times the design pressure corrected for temperature, which means the design pressure must be multiplied by ST/S in the case of process piping. Here, ST=pipe material allowable stress at test temperature, and S=pipe material allowable stress at component design temperature. (Clause 345.4.2) | The hydrostatic test pressure following ASME B31.1 is 1.5 times the piping design pressure. (Clause 137.4.5) |

| 18 | Pneumatic Test Pressure | The pneumatic test pressure as per ASME B31.3 is (1.1 to 1.33) times the design pressure of the piping system. (Clause 345.5.4) | B31.1 instructs to use a pneumatic test pressure between (1.2 to 1.5) times the design pressure for the piping system. (Clause 137.5.5) |

Other differences between ASME B31.1 and ASME B31.3:

The other differences between ASME B31.3 and ASME B31.1 are

- There is a difference in bending and forming requirements in both codes.

- The welder and brazer qualifications are not identical.

- The limitations for the use of cast irons are different in both codes.

- The criteria for using soldered, brazed, and threaded joints are different in both codes.

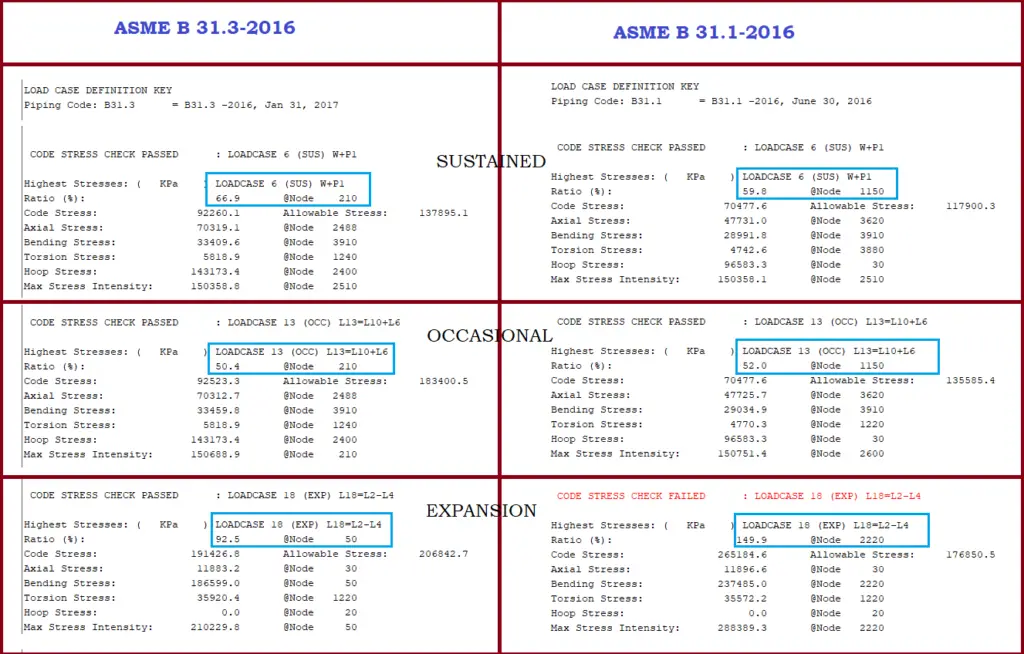

The following image (Fig. 1 ) shows a rough estimate of different stress values of the same system with code change in Caesar II-2018 software:

Understanding the differences between ASME B31.3 and ASME B31.1 is crucial for engineers and professionals involved in the design and maintenance of piping systems. Each code serves a distinct purpose and addresses the specific needs of its respective industry, ensuring that piping systems operate safely and efficiently under their unique conditions.

Some other useful differences for you.

Differences between ASME B 31.4 and ASME B 31.8

13 major differences between Seamless and Welded Pipe

10 Differences between Pressure and Stress

Difference between Tee and Barred Tee

Difference between Stub-in and Stub-on Piping Connection

Difference between Centrifugal and Reciprocating Compressor

Difference between PDMS and PDS

Difference between Piping and Pipeline

Difference between Pipe and Tube

Difference between Primary load and Secondary load

Difference between Caesar II and Start-Prof

Difference between API and ANSI Pump

your contents are always useful and valuable. please continue, such that it will be helpful for lot of freshers and entry level engineers.

Why does power piping have to be more reliable than process piping?

In case of power piping operating pressure and temperature is high as compared to process piping , so to add extra safety factor we generally go for conservative design in case of power piping

Anup Sir please Explain why sustain and expansion stresses they have different allowable limits in codes. Is there any derivation for that

? Please Explain in brief.

Dear Sir,

Can you please provide the reference/Standard for PT/MT requirements for down comer and riser lines

furnace 31.1

Please can I have the pdf of asme B31.3,31.1,31.4 and 31.8

I currently work for a district heating utility, and was written up for what I believed was the proper action. Was told cut out a 4’ section of 6” pipe with two threaded 45 fitting, that had small leak at the threads on a low pressure line in a customer basement on a line that feeds three others. After the asbestos was removed it exposed a threaded 6” tee that was blanked. My concern was welding in piping 2” to 3”inches away from a cast threaded fitting would cause the threads to leak or possibly damage the fitting from thermal restricted expansion. That the 6” threaded fitting was not to code and it is a code violation to blank a tee. I removed the tee and had my welder installed a 90. I was told that it was not part of the plan to remove the tee and that because it was low pressure code doesn’t apply. Note: the LP steam is 15psi however I have see it in the 20s and it’s reduced from 150psi without safety valves.

Thank sir. This very useful..

Thank You for share this valuable information

Good information, Thanks for sharing.

In Sl. no.2, please correct to ASME B 31.1 instead of ASME B31.3 on both.

This very useful data for fresher engineers and I cleared all my doubts.thanks a lot

Useful information. Thank you

How can this content be downloaded?

Kindly go to the end of the respective article. Buttons for creating pdf and downloading is provided at the end of each article. However, as each article is dynamic and updated frequently it is preferable to read from the website. You can search for any article and read it directly from the website.

I have a question. In the comparison of B31.1 and B31.3, where can the standard of design life be seen in the code?

dear Anup,

Thank you for summarizing some very important aspects/rules about ASME B31.3 and B31.1.

Your article motivates to learn and improve knowledge.

Any specific requirement of seal weld in codes ?

SIR which ASME to be adopted for hydro test of

31/2″tubing (drilling)

A solda de uma derivação entre uma tubulação de 60″ e 28″, onde a derivação de 28″ vai ser instalada em cima da solda circuferencial da tubulação de 60″. De acordo com a ASME B31.3 é permitido? Qual item da norma permite?

Agradeço