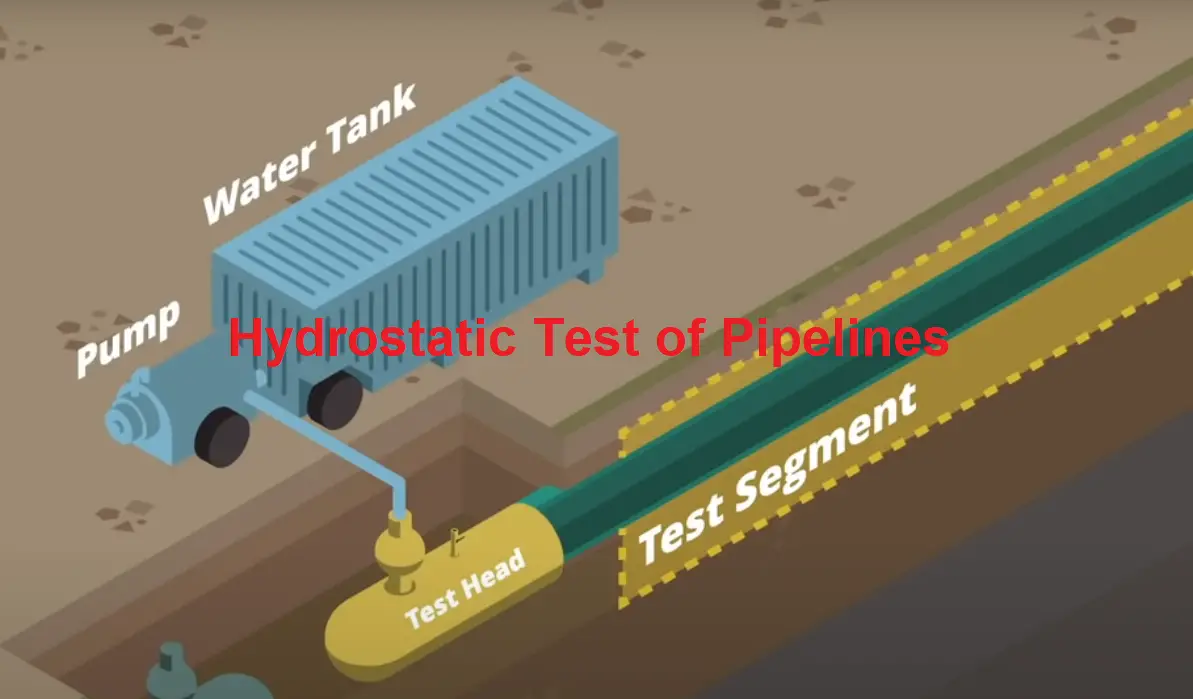

We all know that a hydrostatic test is performed in all piping systems to ensure the integrity of all the joints. It is a code requirement before the commissioning of the piping/pipeline system. However, in certain situations, hydrostatic testing may not be technically feasible or may be hugely cost-intensive. For example, When a new piping component is connected to an already existing pipe. The situation may not always be favorable for hydro tests. In such a situation, the golden joint comes as a savior to construction professionals. The joint is called “golden” because of its highly critical nature and the importance of its quality. In this article, we will learn the meaning and applications of golden joints in piping.

What is a Golden Joint?

Golden Joint is a pipe/pipeline joining procedure where hydro testing is not performed after the joining. Extensive NDT methods like radiographic test/ultrasonic testing methods are used to ensure that the joint is defect-free, design is in line with codes and standards, and fit for intended service. A golden joint is also known as a golden weld or closure weld.

Examples of Golden Joints

Some typical examples of golden joints are:

- Golden joints in tie-ins from existing pipe parts.

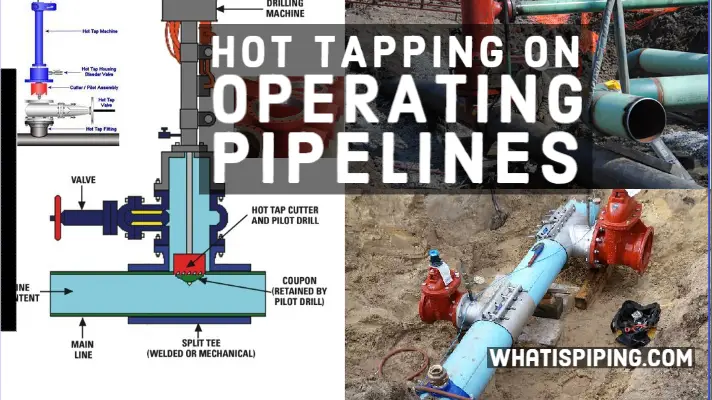

- During Hot tapping from running/working/operating pipelines.

- When only a little repair work is performed on the system at one or two locations, and hydro-testing of the complete system is difficult, costly, and time-intensive.

Golden Joint Procedure

The requirements of golden weld joints are identified by the construction contractor. Then they mark up the isometric/alignment drawings and get permission from the client. Next following a proper golden joint fabrication method statement, the welding is performed. Next NDE and final inspection clearance is taken and the golden joint is approved. The golded weld or closure weld must be performed by a highly skilled welder.

NDE requirements for Golden Joints

Non-destructive examination or NDE is performed after the PWHT if required by the piping class, thickness, and service limitation. In general, the following NDT tests are performed for golden piping joints.

- Radiographic Testing: Radiographic testing can be performed as per the guidelines provided in Article 2 of ASME BPVC Code section V.

- Ultrasonic Testing: Ultrasonic testing can be performed as per the guidelines provided in Article 5 of ASME BPVC Code section V.

- Magnetic Particle Testing: Magnetic Particle Testing is performed as per the guidelines provided in Article 7 of ASME BPVC Code section V.

- Dye Penetration Test: Dye Penetrant testing is performed as per the guidelines provided in Article 6 of ASME BPVC Code section V.

Code requirements for Golden Joints

ASME B31.3 Requirements for Golden Joint

As per clause 345.2.3 (c) of ASME B31.3, The final weld connecting piping systems or components need not be leak tested (golden weld) provided the weld is examined and passes with 100% radiographic examination or 100% ultrasonic examination.

ASME B31.4 and ASME B31.8 codes also permit the use of golden pipeline welds for tie-in joints.

Golden Weld Joint ASME B31.4:

Clause 437.1.4-b of ASME B31.4 provides requirements for golden welds. It states:

Testing Tie-Ins. Because it is sometimes necessary to divide a pipeline into test sections and install test heads, connecting piping, and other necessary appurtenances for testing, or to install a pretested replacement section, it is not required that tie-in welds be tested; however, tie-in welds and girth welds joining lengths of pretested pipe shall be inspected by radiographic or other accepted nondestructive methods in accordance with para. 434.8.5(b) if the system is not pressure tested after tie-in. After such inspection, the joint shall be coated and inspected in accordance with para. 461.1.2 before backfilling.

ASME B31.8 requirements for Golden Joints

Clause 841.3.1-a of ASME B31.8 specifies the requirements for golden welds. As per this code:

The circumferential welds associated with connecting pretested assemblies, pretested repair pipe lengths or sections, and welded tie-in connections are not pressure tested after construction in accordance with para. 841.3.2 or para. 841.3.3 or leak tested after construction in accordance with para. 841.3.4 or para. 841.3.5 shall be examined by radiography, ultrasonics, magnetic particle, or other comparable and accepted non-destructive methods in accordance with paras. 826.3 (c) and 826.3(d).

API 570 Requirements for Golden Weld Joints of Piping

As per API 570, when performing a pressure test of a final closure weld that joins a new or replacement section of piping to an existing system is not practical, all of the following four requirements need to be satisfied.

- a) The new or replacement piping section is pressure tested and examined by the applicable code governing the design of the piping system, or if not practical, welds are examined with appropriate NDE, as specified by the authorized piping inspector.

- b) The closure weld is a weld between any pipe or standard piping component of equal diameter and thickness, axially aligned (not miter cut), and of equivalent materials.

- c) Any final closure butt weld shall be of 100 % RT; or angle beam ultrasonic flaw detection may be used, provided the appropriate acceptance criteria have been established.

- d) MT or PT shall be performed on the root pass and the completed weld for butt welds and on the completed weld for fillet welds.

The owner/user shall specify industry-qualified UT angle beam examiners for closure welds that have not been pressure tested and for weld repairs identified by the piping engineer or authorized piping inspector.

API RP 14-E Requirements for Golden Joint

API RP 14E recommends that when hydrostatic or pneumatic tests create any adverse effect on the piping or operating fluid, a golden joint can be used.

Applications of Golden Joints

As explained above, Golden Joints are commonly encountered in the following situations:

- Pipeline/Piping Tie-Ins: When connecting new sections of pipeline or piping to existing systems.

- Facility Modifications: During the integration of new equipment or piping into an operational system, such as through Hot Tapping.

- Closed-Loop Systems: In scenarios where internal pressure testing is impractical.

- Final Welds in Inaccessible Locations: Where the completion of the last welds is in areas that are difficult to access.

Features of Golden Joints

Common features of Golden Joints include:

- Mandatory Non-Destructive Examination (NDE): Since pressure testing is not used, thorough NDE methods like Ultrasonic Testing (UT) and Radiographic Testing (RT) are required to check the weld for any flaws.

- Strict Welder Qualification: Only highly qualified and certified welders are allowed to perform Golden Joints.

- 100% NDE Coverage: Every layer of the weld must be carefully inspected using NDE techniques.

- Detailed Documentation: Comprehensive records of the welding procedure, welder qualifications, and NDE results are required for future reference and traceability.

Great job and please keep it up

Hello Mr. Kumar;

Thank you very much for conveying your precious knowledge. Always it is practical and very useful to me.

Regards;

Mohammad Amin

Hello , hope this finds you well.

I am a regular reader of your materials and it has really helped me a lot

Please I am looking for training materials or possibly videos of pdms or E3d admin. Will really appreciate if you can give me a link.

Regards. Ibegu

VERY BRIEF KNOWLEDGE ABOUT GOLDEN JOINTS, FOR BEGINNERS AWARENESS