What is ASME B31.4?

Developed and maintained by ASME, ASME B31.4 is the design code for pipelines transporting liquids and slurries between facilities, production, and storage fields, plants, and terminals, and within terminals and pumping, regulating, and metering stations associated with liquid pipeline systems.

What is ASME B31.8?

ASME B31.8 is the design code for pipelines for Gas Transmission and Distribution Piping Systems. This means this code provides design guidelines for piping transporting products that are predominately gas between sources and terminals, including compressor, regulating, and metering stations, and gas gathering pipelines.

ASME B31.4 vs ASME B31.8

So, both the codes, ASME B31.4 and ASME B31.8 are pipeline design codes that cover the design, fabrication, installation, inspection, and testing of pipeline facilities. But, ASME B31.4 deals with pipelines transporting liquids and slurries whereas ASME B31.8 deals with gas transmission and distribution. Now the question is whether both can be used interchangeably and if not then what are the differences between ASME B31.8 and ASME B31.4?

The liquid is incompressible while gas can be easily compressed, So the behavior of both fluids is different under pressure and temperature conditions. Hence, the ASME B31 committee devised two different codes for liquid and gas pipelines.

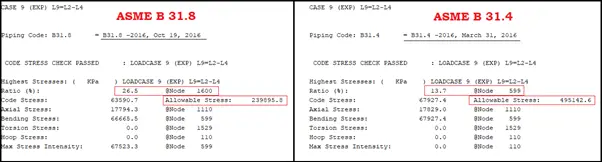

Refer to the following image (Fig. 2) which lists the expansion stress range results for the same stress system with the same parameters analyzed in Caesar II-2018.

Results show that the expansion stress ratio for the system is around double (26.5%) for code ASME B31.8 as compared to ASME 31.4 (13.7%) which means code ASME B31.8 is more stringent from stress analysis consideration.

In this article, we will list some of the major differences between B31.8 and B31.4 in a tabular format. There may be more that we have missed. Kindly request the readers to list those in the comments section and We will add them to the table in due course.

| Parameter | ASME B31.4 | ASME B31.8 |

| Scope | The code ASME B31.4 governs the design requirements for pipeline systems that transport liquid or aqueous slurries of non-hazardous materials | The ASME B31.8 code governs the design requirements for pipeline facilities used for the transportation of gas |

| Exclusions | Building services piping, such as water, air, or steam pressure vessels, heat exchangers, pumps, meters, and other such equipment, including internal piping and connections for the piping casing, tubing, or pipe used in oil wells and wellhead assemblies are not part of ASME B31.4 | Cryogenic piping systems, vent piping to operate at substantially atmospheric pressures for waste gases of any kind, piping in oil refineries or natural gasoline extraction plants, etc are excluded from the scope of ASME B31.8. |

| Minimum Temperature Range | ASME B 31.4 covers pipelines with a temperature above -30 Deg C. | The minimum design temperature as per ASME B31.8 can be reduced further subject to the inclusion of a proper fracture control program for that material. |

| Maximum Temperature Range | The maximum metal temperature limit for ASME B31.4 is 120 Deg C. | ASME B31.8 covers piping with metal temperatures up to 232°C. |

| Allowable Stress | As per ASME B31.4, the allowable stress is dependent only on the specified minimum yield strength of pipe material. | The allowable stress in ASME B31.8 is dependent on the specified minimum yield strength and temperature derating factor which reduces the allowable values when the temperature is more than 120 Deg C. |

| Design Factor F | The Maximum Value of Design Factor F in thickness calculation following ASME B31.4 is 0.72. Lower values can be used as service and location may dictate. | Depending on the location class, the value of F in code ASME B31.8 varies from 0.4 to 0.8 |

| Toughness Requirement | The toughness requirement criteria in B31.4 is comparatively less Stringent. | ASME B31.8 provides more Stringent toughness requirements. |

Few more useful Resources for you..

Few Important points for Stress Analysis based on ASME B 31.4

Pipeline Virtual Anchor Length Calculation

Pipeline wall thickness calculation with example

Comparison between Piping and Pipeline Engineering

A short presentation on Offshore Pipeline Systems

Difference between Tee and Barred Tee

A Presentation on Pipelines – Material Selection in Oil & Gas Industry

Corrosion Protection for Offshore Pipelines

Startup and Commissioning of the Pipeline: An Article

Design of Cathodic Protection for Duplex Stainless Steel (DSS) Pipeline

An Article on Micro Tunneling for Pipeline Installation

An article on Software-Based Pipeline Leak Detection

A small presentation on OFFSHORE PIPELINE DESIGN

A small briefing about “PIPELINE CONSTRUCTION

Hi sir I would like to study about piping sesign as I have enough experience in installation so can you please help me .

Sir thank you for the knowledge. I want to be good in pipeline and storage tank construction and design, can you please teach me? Thank

Dears,

Excellent information, I wanted to ask you if you have comparative information between ASME B31.3 and ASME B31.4, thanks

Dear sir, good morning

i have one question

we are doing water pipe line of 17 km the pipe line materials is API 5L GR X52 3 LP coated and CP protected so we want to use in above ground and under ground connection by flange isolation kits instead of IJ so if it is LPG or any other hydro carbons is it ok foe IJ joint , for the raw water lines we can use flange isolation sets , i need clarification from asme b 31.4

so please clarify me

thanking you sir

ananda rao

it’s so practical and amazing

i need the Calculation for Wall thick and Diameter for Carbon steel pipeline transporting Liquid Petroleum

I have a question: Can i change the service of a currently ASME B31.8 piping to a ASME B31.4, to carry water insted gas?

I find that your material is very helpful.

Can you tell me more about taking a pipeline engineer training course?