Offshore pipelines are the center stage of the subsea transportation system. Any offshore oil and gas projects constitute a long length of offshore pipelines. These are also known as sub-sea pipelines. In the transportation and delivery of carbon products, offshore pipelines play a major role. But the design and laying of offshore pipelines are not easy. It requires many considerations. In this article, we will explore the basics of offshore pipeline projects in brief.

Why offshore pipelines?

Pipelines are used for transportation and delivery services from historic times due to their own advantages like

- Safer

- Environment friendly

- Least energy requirement

- Lowest maintenance costs

- Minimal impact on land use pattern

- Negligible loss of product in transit

- High reliability

What can be transported through Offshore Pipelines?

Offshore pipelines can be used to transport liquids, solids, and gases as per requirement. Normally the following products are used inside offshore pipelines:

- Liquids: Crude Oil, Petroleum Products, Petrochemical Products, Chemicals, Water, LPG

- Solids(in slurry form): Coal, Ores, Tailings

- Gas: Natural Gas, Any other Gas

Flow Sequence of Offshore Pipelines

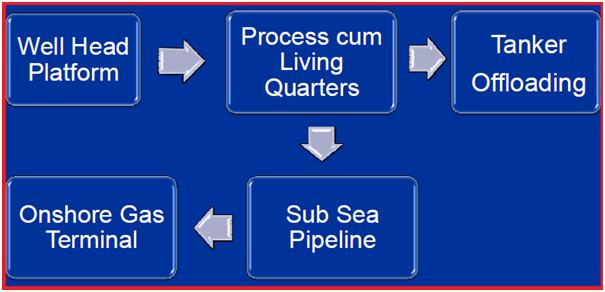

Fig. 1 below shows the sequence of flow for offshore pipeline operations.

Offshore Pipeline and Riser System

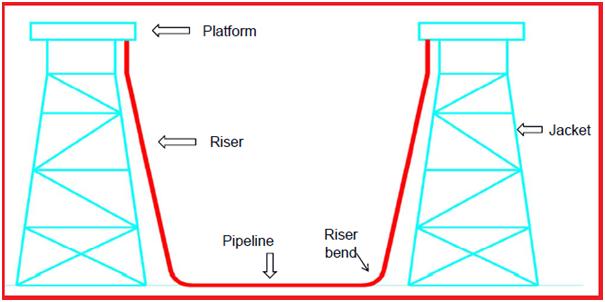

The schematic of an offshore pipeline and riser system is shown in Fig. 2 below:

Stages of an Offshore Pipeline Project

Codes & Standards used in Offshore pipeline projects:

Various codes and standards establish the design guidelines for offshore pipeline systems. The major ones are listed below for reference:

- DNV OS-F101: Det Norske Veritas, Rules for Submarine Pipeline Systems

- ASME B31.8: Gas Transmission and Distribution Piping Systems

- ASME B31.4: Liquid Transportation Systems for Hydrocarbons, LPG and Anhydrous Ammonia, and Alcohols

- API 1104: Standard for Welding Pipelines and Related Facilities

- API 1110: Pressure Testing of Liquid Petroleum Pipelines

- NACE MR0175: Material Requirements – Sulphide Stress Cracking Resistant Materials for Oil Field Equipment

- IP 6: Institute of Petroleum –Pipeline Safety Code

Offshore pipeline Project Stages

All offshore pipeline projects have the following stages before it is ready to take the first fluid.

- Conceptual Study

- Feasibility Study

- Basic Engineering

- Detailed Engineering

- Construction

- Testing & Commissioning

Conceptual Study

In this stage for offshore pipelines, the following major activities are performed.

- Establish System Requirement

- Evaluate Constraints on System Design

- Identify Interface With Other Systems

- Develop Design Data Requirements

- Assess Construction Methodology

- Finalize the Concept

Feasibility Study

The feasibility study is a very important stage for offshore pipeline projects as it evaluates all possible options for the project to decide the feasibility. The major activities of this stage are

- Evaluate Technical Options

- Eliminate Un-viable Options

- Firming up of Process Facilities

- Develop Broad System Specifications

- Establish Project Cost

- Plan Project Implementation Scheme

- Finalize Process Scheme & Equipment

Basic Engineering

Basic Engineering is the next important stage for offshore pipeline projects. The major activities involved in this stage are listed below:

- Environmental & Process Data Review

- Pipeline Routing & Size Optimization

- Establish Requirements for

- Surveys and Investigations

- Material of Construction

- Preliminary Analysis

- Construction, Testing, and Commissioning

- Develop Implementation Schedule

Safety Aspects for offshore pipeline projects

- Environmental Parameter and Soil Data

- Pipeline Stability

- Shore Approaches

- Trenching and Burial

- Safety of Existing Facilities

Detailed Design & Engineering

The main or the most important stage of any offshore pipeline project phase is detailed engineering. Most of the design works are studied in detail and completed in this stage.

- Engineering Design Basis

- Route Engineering & Surveys

- Engineering analysis and Calculations

- Specification and Job Standards

- Engineering for Procurement

- Drawings for Construction

- Installation analysis and Procedures

Design Basis

The engineering design basis provides all the governing criteria to follow in the pipeline project. It provides the

- Basic Data

- Design Codes and Standards

- Design Philosophy

- Operation and maintenance philosophy

- Environmental Criteria

- Installation

- Operation

- Criteria for engineering analysis

Route Selection

Pipe route selection for offshore pipelines is very important and it is an exhaustive activity. It includes the following considerations:

- Routing Considerations

- Pipeline length

- Sensitive areas

- Obstructions

- Installation Limitations

- Crossings

- Drilling Rig Movement / Access

- Surveys

- Geo-physical & Geotechnical Surveys

- Platform Approach / Riser Face Survey

Offshore Pipeline Wall Thickness Selection

The wall thickness of offshore pipelines is calculated and selected considering all possible failure stages. It includes

- Analysis / Calculations

- Hoop Stress

- Buckle Initiation

- Buckle Propagation

- Collapse Bucking

- Local Buckling

- Pipeline Stress Checks

- Equivalent Stress

- Analysis Tools

- PC Based Software ‘Pipecalc’

Wall Thickness Calculation

For Offshore Pipelines t = (PD/2.SMYS.a) + corrosion allowance where

- P is the internal design pressure in psig.

- S is the specified minimum yield strength

- D is the pipe’s outside diameter in inches.

- t is the nominal wall thickness in inches.

- a is the design factor (0.72 for pipeline and 0.5 for riser)

Allowable Stress Limits for Offshore Pipeline Systems

Fig. 3 below provides the allowable stress limits for offshore pipeline and riser systems.

Types of Line pipes in Offshore systems

A variety of pipeline sizes is used in offshore pipeline projects. Normally following line pipes are used:

- Seamless up to 16″

- LSAW 18” and above

Engineering Analysis

Various engineering analyses need to be done in the complete design life cycle of offshore pipelines including the following

- Stability Pipeline (Lateral & Vertical)

- Pipeline Expansion

- Pipeline Spans

- Riser

- Analysis Tools

- PC Based Software ‘Pipecalc’

Anti Corrosion Coatings

- Coating Anti-Types

- Coal Tar Enamel

- Fusion Bonded Epoxy

Selection Criteria

- Service Conditions

- Performance Record

- Ease of Repair

- Cost-Effectiveness

- Compatibility with Concrete Coating

Design for Offshore Pipeline Crossing

- Exposed Pipelines (Single / Multiple)

- Buried Pipelines (Single / Multiple)

Stress Analysis of Offshore pipelines

Stress analysis (Both static and dynamic) must be performed for all offshore pipeline systems to ensure code and engineering compliance with

- Permissible Spans

- Stability of Supports

- Deflections

- Stresses, etc

Design Tools for Offshore Pipelines

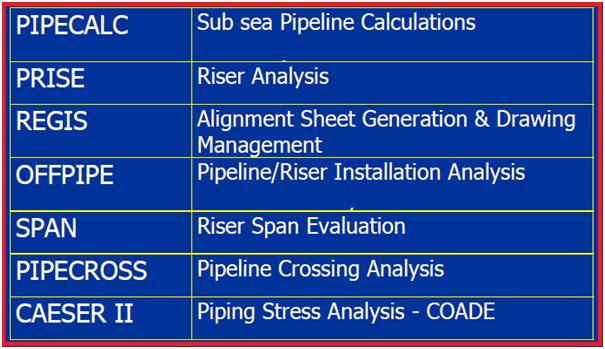

Fig. 4 below lists a few of the design tools that are used for the design of offshore pipeline and riser systems.

Online Video Courses related to Pipeline Engineering

If you wish to explore more about pipeline engineering, you can opt for the following video courses

- Pipeline Stress Analysis using Caesar II

- Design of Underground Pipeline Supports

- Hot Tapping in Piping and Pipeline Industry

- Buried or Underground Pipeline Stress Analysis using Caesar II

Few more Pipeline related useful Resources for You..

Underground Piping Stress Analysis Procedure using Caesar II

Comparison between Piping and Pipeline Engineering

A Presentation on Pipelines – Material Selection in Oil & Gas Industry

Corrosion Protection for Offshore Pipelines

Start up and Commissioning of the Pipeline: An Article

DESIGN OF CATHODIC PROTECTION FOR DUPLEX STAINLESS STEEL (DSS) PIPELINE

AN ARTICLE ON MICRO TUNNELING FOR PIPELINE INSTALLATION

A short presentation on: OFFSHORE PIPELINE SYSTEMS: Part 1

Factors Affecting Line Sizing of Piping or Pipeline Systems

Dear Sir,

Thank you for your great posts in here. I have found many interesting information from this website

It will be very appreciate if you have a post to describe more detail consideration in stress analysis for offshore project.

Regards,

I am getting very valuable information, thanks a lot.

Very valuable information for both freshers & experienced!

Dear Sir,

Thank you for your great posts in here. I have found many interesting information from this BLOG.

It will be very appreciate if you have a post to describe more detail consideration in stress analysis for offshore project.

Regards,

Prathamesh SM