When it comes to versatile materials that have found their way into numerous industries and everyday applications, neoprene certainly deserves a spot in the limelight. Neoprene pads, in particular, are a standout product in this family. This synthetic rubber material is celebrated for its remarkable properties, making it a go-to choice for various applications ranging from industrial to recreational. In this article, we’ll dive into the world of neoprene pads, exploring what makes them so unique and their myriad of uses.

What is Neoprene?

Neoprene is a type of synthetic rubber made from chloroprene polymerization. It was first developed by American chemical conglomerate DuPont in the 1930s and quickly became popular due to its impressive blend of qualities. Neoprene is prized for its flexibility, resistance to various environmental factors, and its excellent chemical stability.

What is a Neoprene Pad?

Neoprene pads, often referred to simply as “neoprene sheets” or “neoprene rubber pads,” are cut from larger neoprene rolls or sheets. These pads inherit all the exceptional characteristics of neoprene and are designed to serve a wide array of purposes. Neoprene pads are available in a range of styles and sizes.

Properties of Neoprene Pads

Here are some of the key features that make neoprene pads so versatile:

Weather Resistance:

Neoprene pads are known for their exceptional resistance to weathering, ozone, and UV rays. This makes them an ideal choice for outdoor applications, where exposure to the elements is a concern.

Temperature Tolerance:

Neoprene pads can handle a broad range of temperatures, from extremely cold to quite hot, without significant degradation. This quality is crucial in applications where temperature fluctuations are common.

Chemical Resistance:

Neoprene exhibits good resistance to a variety of chemicals, oils, and solvents, making it a valuable material in industrial settings where exposure to these substances is a possibility.

Cushioning and Shock Absorption:

Neoprene’s natural elasticity and compressibility make it excellent for cushioning and absorbing shocks. This property is essential in applications such as gaskets, seals, and padding.

Flexibility:

Neoprene pads are highly flexible, allowing them to conform to irregular shapes and contours. This makes them versatile for various custom applications.

Other various properties of Neoprene pads include:

- Compression Set Resistance: Neoprene pads are resistant to compression sets, meaning they can withstand sustained compression without losing their shape or effectiveness. This property makes them suitable for long-term use in applications like gaskets and seals.

- Buoyancy: Neoprene is naturally buoyant and floats on water, making it valuable in marine and water sports applications.

- Insulation: Neoprene has excellent insulating properties, which make it effective for maintaining temperature stability. It is often used to insulate pipes, tanks, and electrical components.

- Sound Dampening: Neoprene’s elasticity and density make it effective at reducing vibrations and noise. It is commonly used for soundproofing applications in construction and industrial settings.

- Abrasion Resistance: Neoprene pads have good resistance to abrasion, which helps prolong their lifespan in applications where they may come into contact with abrasive surfaces.

- UV Resistance: Neoprene is resistant to ultraviolet (UV) radiation, making it suitable for outdoor applications where prolonged sun exposure is a concern.

- Tear Resistance: Neoprene is generally tear-resistant, which adds to its durability and suitability for applications requiring strength and resilience.

- Adhesive Compatibility: Neoprene pads can be easily bonded to various surfaces using compatible adhesives, enhancing their versatility for different applications.

- Water Resistance: Neoprene inherently repels water, making it a popular choice for wet environments, such as wetsuits and marine accessories.

- Biocompatibility: Medical-grade neoprene, which is free from harmful additives, is biocompatible and suitable for use in medical and orthopedic devices.

Mechanical Properties of Neoprene Pads

When it comes to mechanical properties, Neoprene pads have excellent elasticity, moderate to high tensile strength, and good compressive strength. They are resilient, abrasion-resistant, and tear-resistant. Neoprene pads exhibit good impact resistance and reasonable fatigue resistance. They have lower modulus of elasticity but provide good damping properties to absorb and reduce vibrations. The Pads of Neoprene support loads effectively and have good shear strength.

The Shore A hardness of Neoprene Pads ranges between 40 to 95. The ultimate tensile failure stress is ranging from 500 to 3000 psi.

Applications of Neoprene Pads in the Oil and Gas Industry

Neoprene pads find valuable applications in the oil and gas industry due to their excellent combination of properties, including resistance to harsh environmental conditions, chemicals, and temperature variations. Here are some key applications of neoprene pads in this industry:

Pipeline Supports and Cushioning:

Neoprene pads are used as supports and cushioning materials for pipelines and pipe hangers. They help absorb vibrations, reduce stresses on pipes, and provide thermal insulation. These pads are crucial for maintaining the integrity of pipelines, especially in areas with seismic activity.

Turbine and Equipment Mounting:

Neoprene pads serve as vibration isolators and shock absorbers for large equipment and machinery used in oil and gas facilities. They reduce noise and vibration, extending the lifespan of the equipment and ensuring smooth operation.

Tank and Vessel Insulation:

Neoprene pads are applied to the surfaces of tanks and vessels to provide thermal insulation. They help prevent heat loss or gain, maintaining consistent temperatures within storage tanks, which is crucial for the preservation and transportation of various petrochemical products.

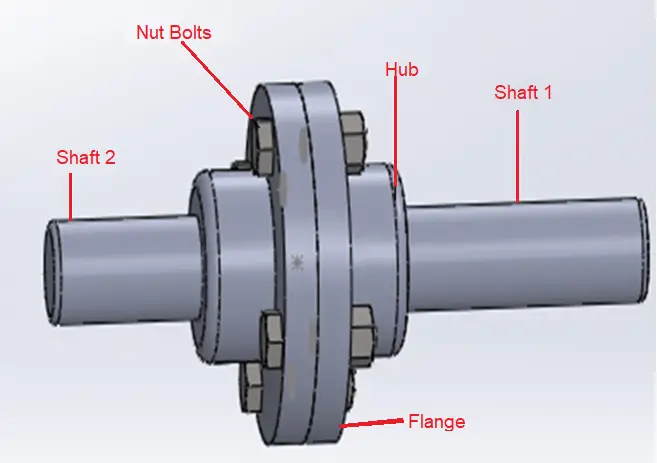

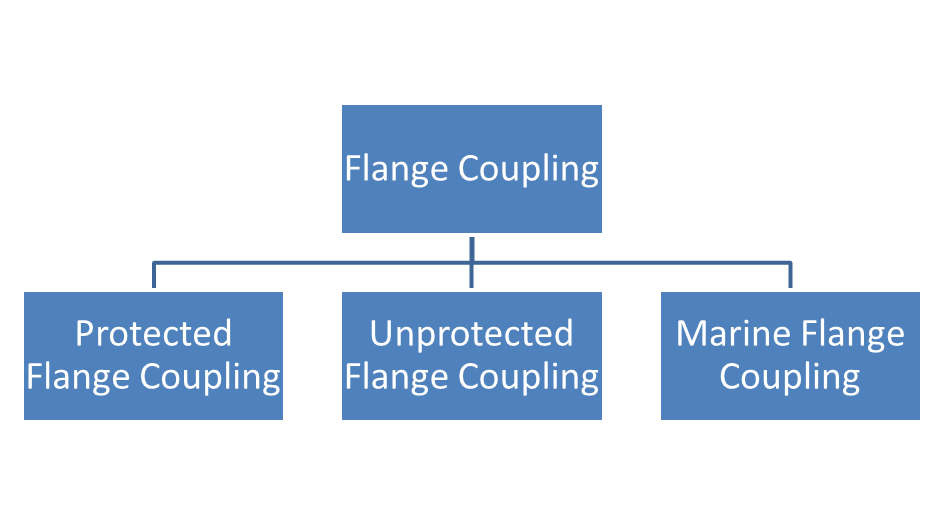

Flange Gaskets:

Neoprene gaskets are commonly used in flange connections to create a reliable and leak-free seal in pipes, valves, and pumps. They are resistant to oil, chemicals, and extreme temperatures, making them ideal for the demanding conditions of the oil and gas industry.

Pipeline Padding and Coating:

Neoprene pads are used to pad and coat pipes, especially in offshore applications where protection against corrosion and mechanical damage is essential. They provide a protective barrier against abrasion and impact.

Expansion Joint Seals:

Neoprene is often used in expansion joints to provide a flexible seal that can accommodate the expansion and contraction of pipes and structures due to temperature changes. This prevents leaks and structural damage.

Offshore Platform Components:

Neoprene is used in various components of offshore platforms, including seals for cable penetrations, vibration isolators for machinery, and protective covers for sensitive equipment exposed to saltwater and harsh weather conditions.

Subsea Cable Protection:

Neoprene pads are used to protect subsea cables and umbilicals from mechanical damage and abrasion. They provide a resilient barrier that helps ensure the integrity of critical connections in underwater operations.

Personal Protective Equipment (PPE):

Neoprene is used in the manufacturing of PPE for oil and gas workers. Neoprene gloves, suits, and boots provide protection against chemicals and cold water, making them suitable for offshore drilling and maintenance operations.

Wellhead Seals:

Neoprene seals are employed in wellhead assemblies to maintain the integrity of the well and prevent the escape of oil or gas. They resist the harsh chemicals and high pressures found in wellhead operations.

Sealing and Insulation in Downhole Tools:

Neoprene is used in downhole tools and equipment to create seals and provide insulation. It helps protect sensitive components from extreme temperatures, pressure, and corrosive fluids encountered during drilling and production.

Floating Roof Tank Seals:

Neoprene seals are used in floating roof tanks to prevent the evaporation of stored oil and to maintain a vapor-tight seal. These seals are critical for environmental compliance and preventing product loss.

Other Applications of Neoprene Pads

Cushioning and Padding:

In sports and recreational equipment, neoprene pads find their way into knee pads, elbow pads, wetsuits, and even in the soles of shoes to provide cushioning and shock absorption.

Sound Dampening:

Neoprene pads are effective at reducing vibrations and noise, making them an excellent choice for soundproofing applications in construction and industrial settings.

Medical and Orthopedic Devices:

Neoprene’s comfort and flexibility make it suitable for medical braces, orthopedic supports, and prosthetic limb padding.

Automotive Applications:

Neoprene pads are used in automotive manufacturing for various purposes, including vibration isolation, weather sealing, and interior padding.

Marine and Water Sports:

Due to its resistance to water and UV radiation, neoprene is commonly found in wetsuits, life vests, and marine accessories.

Crafts and DIY Projects:

Neoprene’s ease of use and availability in various thicknesses make it popular among DIY enthusiasts for crafting, from making laptop sleeves to custom cosplay costumes.

Neoprene Pads for Pipe Supports

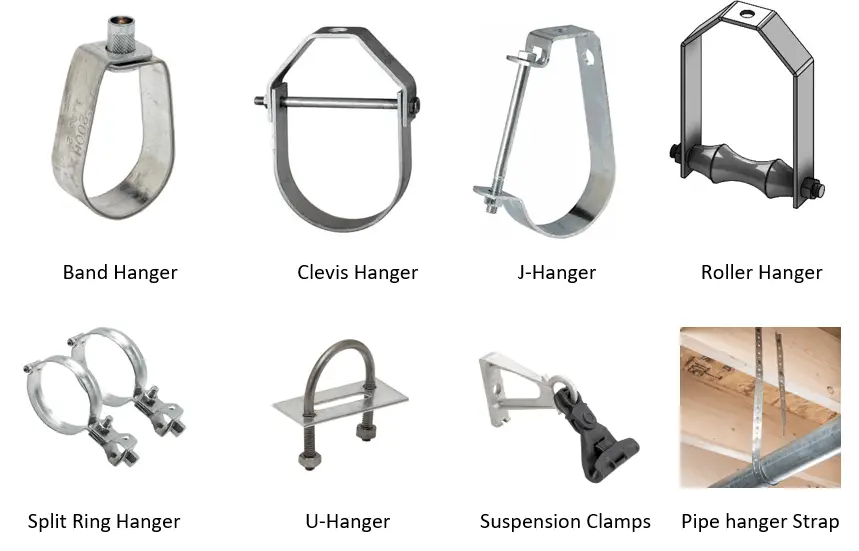

Often Neoprene Pads are used in pipe supports as an isolation medium between piping and supports. U-bolts and clamps are separated from the pipe materials by inserting a neoprene pad in between. The coefficient of friction for Neoprene to Steel in pipe supporting is considered to be 0.4. For alloy steel pipes, clamps shall be supplied with a 2 mm thick Neoprene coating on the inside surface.

Neoprene Pads for Construction

Neoprene pads for construction are specialized components made from neoprene rubber. They are used in construction projects to serve various purposes, including load distribution, cushioning, vibration isolation, and thermal insulation. These pads are often placed between structural elements, such as beams, columns, or machinery, and their foundations or support structures. Neoprene pads help reduce vibrations, absorb shocks, distribute weight evenly, and provide protection against temperature fluctuations and moisture in construction applications.

Neoprene Pads for HVAC Equipment

Neoprene pads for HVAC (Heating, Ventilation, and Air Conditioning) equipment are neoprene rubber components designed specifically for use in HVAC systems. They serve as vibration isolators and shock absorbers for HVAC equipment like air compressors, condenser units, and fans. These pads are placed under the equipment to dampen vibrations, reduce noise, and prevent the transfer of vibrations to the building structure. They help improve the efficiency and longevity of HVAC systems while minimizing the impact on the surrounding environment.

Neoprene Pads for Bridges

Neoprene pads for bridges are specialized rubber components used in the construction and maintenance of bridges. They are typically placed between the bridge’s superstructure (such as beams or girders) and the bridge’s substructure (such as piers or abutments). Neoprene bridge pads serve several functions, including load distribution, shock absorption, and accommodating thermal expansion and contraction of bridge components. These pads help protect the structural integrity of the bridge, mitigate the effects of traffic loads and temperature fluctuations, and extend the lifespan of the bridge.

Vibration Isolation Neoprene Pads

Vibration isolation neoprene pads are neoprene rubber components designed specifically to isolate machinery and equipment from vibrations and shocks. These pads are placed under the equipment or between the equipment and its support structure. They are engineered to absorb and dissipate vibrational energy, preventing it from being transmitted to the surrounding environment or structure. Vibration isolation neoprene pads are commonly used in industrial settings to reduce noise, protect sensitive equipment, and improve the performance and longevity of machinery by minimizing the impact of vibrations.

Conclusion

The neoprene pad, born from the remarkable material known as neoprene, is a versatile wonder that has found its way into countless applications across different industries. Whether it’s sealing, cushioning, insulating, or providing support and comfort, neoprene pads have proven their worth time and time again. As technology and manufacturing processes continue to evolve, we can expect to see even more innovative uses for this remarkable material in the future.

FAQ

What are Neoprene Pads?

Neoprene pads are rubber components made from synthetic rubber known as neoprene. They are versatile and commonly used for various applications due to their properties, including flexibility, resilience, and resistance to environmental factors.

What are the main properties of Neoprene Pads?

Neoprene pads exhibit properties such as weather resistance, temperature tolerance, chemical resistance, flexibility, elasticity, and excellent shock absorption capabilities. These properties make them suitable for a wide range of applications.

What are the typical applications of Neoprene Pads?

Neoprene pads find applications in gaskets and seals, cushioning and padding, insulation, sound dampening, medical and orthopedic devices, automotive components, marine equipment, crafts, and DIY projects, among others.

How are Neoprene Pads used in the construction industry?

Neoprene pads are used in construction to distribute loads, absorb vibrations, and provide thermal insulation. They are commonly placed between structural elements and their foundations or support structures.

What is the role of Neoprene Pads in HVAC equipment?”

Neoprene pads in HVAC equipment act as vibration isolators and shock absorbers. They are placed under HVAC components to reduce vibrations, noise, and the transmission of vibrations to building structures.

How do Neoprene Pads benefit bridges?

Neoprene pads for bridges help distribute loads, absorb shocks, and accommodate thermal expansion and contraction. They protect bridge integrity, extend lifespan, and reduce the impact of traffic loads and temperature changes.

Are Neoprene Pads resistant to chemicals?

Yes, neoprene pads are known for their resistance to various chemicals, oils, and solvents, which makes them suitable for industrial applications where exposure to such substances is possible.

How do I choose the right Neoprene Pad for my application?

Consider factors like pad thickness, durometer (hardness), and specific properties needed (e.g., weather resistance, temperature tolerance). Consult with a supplier or manufacturer to ensure you select the most suitable neoprene pad for your application.

Can Neoprene Pads be customized for specific applications?

Yes, neoprene pads can be cut or shaped to fit specific shapes and sizes, and they can be customized to meet the requirements of different applications. Customization ensures a precise fit and performance.

How do I maintain Neoprene Pads?

Regularly inspect neoprene pads for signs of wear or damage. Replace damaged pads promptly to ensure they continue to provide the intended function. Clean them as needed with mild detergent and water.

Are Neoprene Pads eco-friendly?

Neoprene is a synthetic material, and its environmental impact can vary depending on manufacturing processes. Some versions of neoprene are more eco-friendly than others. Look for neoprene products that adhere to environmental standards if sustainability is a concern.

Can Neoprene Pads withstand extreme temperatures?”

Yes, neoprene pads can withstand a wide range of temperatures, from extreme cold to high heat, without significant degradation. This makes them suitable for applications in varying environmental conditions.