Piping systems are the veins of industrial plants, carrying fluids and gases critical for various processes. Ensuring the reliability and safety of these piping systems is paramount, and this is where Advanced Pipe Stress Analysis comes into play. Advanced Pipe Stress Analysis goes beyond basic analysis, offering a comprehensive understanding of how pipes behave under various conditions.

Pipe Stress Analysis is a critical aspect of piping design that evaluates the effects of loads, pressures, and thermal gradients on a piping system. Basic Pipe Stress Analysis typically considers factors like pressure, temperature, and weight to ensure the system’s integrity. However, as systems become more complex and industries demand higher efficiency, Advanced Pipe Stress Analysis becomes essential.

Various sophisticated software tools are essential for Advanced Pipe Stress Analysis. One such powerhouse in the field is Caesar II. Developed by Hexagon PPM, Caesar II is a widely used software application that plays a pivotal role in ensuring the integrity and reliability of piping systems. Caesar II allows engineers and designers to model, analyze, and optimize piping systems. Known for its robust capabilities, the software enables a comprehensive evaluation of various factors influencing pipe behavior, providing a detailed understanding of stress, deformation, and stability under different operating conditions. Throughout the course, the explanations and case studies are provided using Caesar II software.

The complete online pipe stress analysis course is divided into several modules. Each module will explain some aspects of Pipe Stress Analysis that are required for every pipe stress engineer. New modules will be added as and when prepared. You can enroll in the module that you require.

Module 1: Basics of Pipe Stress Analysis (Duration: 5 hours)

- Click here to join the course. You will learn the following:

- How to Use Caesar II Software

- Creating a 3D model of the piping system adding piping, components, fittings, supports, etc

- Modeling equipment connection in Caesar II

- Basics Theory of Pipe Stress Analysis

- Load Case Preparation

- Analyzing the system and reviewing the Results

Module 2: Pipe Support Engineering (Duration: 2 hours)

- Join the module by clicking here. The support engineering module will cover the following details:

- Role of Pipe Supports in Piping Design

- Types of Pipe Supports

- Pipe Support Spacing or Span

- How to Support a Pipe

- Pipe Support Optimization Rules

- Pipe Support Standard and Special Pipe Support

- Pipe Support Engineering Considerations

Module 3: ASME B31.3 Basics for Pipe Stress Engineer (Duration: 1.5 hrs)

- To enroll in this module click here. You will learn the following:

- Learn the basics from ASME B31.3 required for a pipe stress engineer

- Learn Code equations that stress analysis software use

- Learn the allowable values for different types of code stresses

- Learn Material allowable stresses

- Learn to calculate pipe thickness as per ASME B31.3

Module 4: Stress Analysis of PSV/PRV Piping System in Caesar II (Duration: 1 hr)

- Enroll in this module by clicking here. This module covers

- Brief about Pressure Safety Valve Systems

- PSV Reaction Force Calculation

- Application of PRV Reaction Force in Stress System

- Case Study of Stress Analysis of PSV System using Caesar II Software

- Best Practices for PSV Piping Stress Analysis

Module 5: Flange Leakage Analysis in Caesar II (Duration: 1 hr)

- Click here to enroll in this module. It covers

- Reasons for Flange Leakage

- Basics of Flange Leakage Analysis

- Types of Flange Leakage Analysis

- Case Study of Flange Leakage Analysis using Caesar II (Case Studies of Pressure Equivalent Method, NC 3658.3 method, ASME Sec VIII method)

Module 6: Spring Hanger Design and Selection (Duration: 1.5 hours)

- Here is your module for registering. Spring hanger module covers:

- What is a Spring Hanger?

- Types of Spring Hangers

- Differences between Variable and Constant Spring Hangers

- Design and Selection of Spring Hangers

- Case Study of Spring Hanger Design and Selection Using Caesar II

Module 7: WRC 537/WRC 297 Calculation in Caesar II (Duration: 1 hr)

- To join the module click here. It will cover the following:

- What is WRC 537 and WRC 297

- When to Perform WRC Calculation

- Steps for WRC Calculation

- Practical Case Study of WRC Calculation

Module 8: Buried Pipe Stress Analysis (Duration: 1.5 hr)

- Click here to enroll for this course. It covers

- Learn how to model buried piping and pipeline systems in Caesar II software

- Additional Inputs required for buried pipe stress analysis

- Create load cases based on ASME B31.3/B31.4/B31.8 codes

- Perform the underground/buried pipe stress analysis

- Review the results calculated by the software and understand their meanings

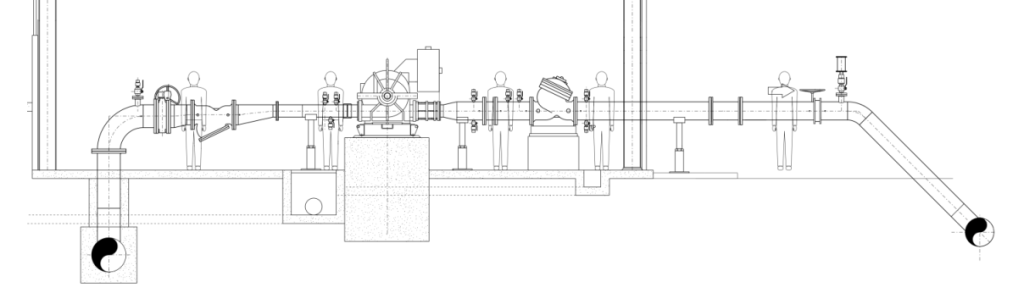

Module 9: Pump Piping Stress Analysis Using Caesar II (Duration: 2.5 hrs)

- To enroll in this course proceed by clicking here. The course briefly covers

- Learn the basics of pump piping stress analysis.

- Learn to create load cases for pump piping analysis in Caesar II software.

- Learn to read data from pump GA to model and analyze using Caesar II.

- Practical Case Study of a Pump Piping Stress Analysis

Module 10: Static and Dynamic Analysis of Slug Flow in Caesar II (Duration: 1.5 hrs)

- To learn from this course click here. It covers

- Basics of Slug Flow Analysis

- Calculation of Slug Forces

- Application of Slug Forces

- Static Analysis of Slug Flow

- Dynamic Analysis of Slug Flow

Module 11: FRP-GRP-GRE Piping/Pipeline Stress Analysis Using Caesar II (Duration: 1.5 hrs)

- Proceed here to enroll in this module of the course. It briefly explains

- Basics of FRP/GRE/GRP Piping

- Inputs to ask from the vendor for FRP/GRP/GRE Pipe Stress Analysis

- Modeling and Analyzing GRP/FRP/GRE Piping system in Caesar II

- Flange Leakage Checking for FRP Piping Systems

- FRP Pipe Supporting Guidelines

Module 12: Pipeline Stress Analysis using Caesar II (Duration: 1.5 hrs)

- Click here for enrolling in this module. This module covers

- Liquid and Gas Pipeline Stress Analysis using ASME B31.4 and ASME B31.8

- Difference between Piping and Pipeline

- Differences between ASME B314 and ASME B31.8

- Use Caesar II software for pipeline stress analysis with a practical case study

Module 13: Dynamic Analysis of Piping Systems in Caesar II Software (Duration: 1.5 hrs)

- Join this module by clicking here. This module covers

- Dynamic Analysis Basics

- Static Analysis vs Dynamic Analysis

- Types of Dynamic Analysis

- Modal Analysis Case Study

- Response Spectrum Analysis Case Study

Module 14: Guide to Reviewing a Pipe Stress Analysis Report (Duration: 1 hr)

- Click here for joining this module. It covers

- Learn How to Review a Pipe Stress Analysis Report

- Requirements of Pipe Stress Analysis Report

- What to Review in a Pipe Stress Analysis Report

- Practical Sample Review Process

- Steps for Reviewing Pipe Stress Analysis Report

Module 15: Flow-Induced Vibration Analysis of Piping System (Duration: 1 hr)

- Enroll in the FIV analysis module by clicking here. It covers:

- Common causes of piping vibration and their effects.

- Definition of Flow-Induced Vibration.

- Reasons for FIV in a piping system.

- FIV Study/Analysis Steps Based on Energy Institute Guidelines

- Mitigation Options of FIV Study Results.

Module 16: Acoustic Induced Vibration Basics for Piping Systems (Duration: 45 Mins)

- Click here to enroll in this module. This module covers:

- What is Acoustic-Induced Vibration or AIV?

- Causes and Effects Of Piping Vibration

- Acoustic-Induced Vibration Analysis Steps

- Mitigation of AIV

Module 17: Storage Tank Piping Stress Analysis (Duration: 1 hr)

- Click here to enroll in this module. Storage tank piping stress analysis module covers the following

- Differences between a storage tank and a pressure vessel?

- Types of storage tanks used in oil and gas industries

- Why is storage tank piping critical?

- What is Tank settlement?

- What is Tank bulging?

- Storage Tank Nozzle Load Qualification

- Practical case study of storage tank piping analysis

Module 18: Stress Analysis of Tower/Vertical Column Piping System (Duration: 1.5 hrs)

- To join Module 18, Click here. This module Covers:

- Application of Vertical Columns/Towers

- Inputs Required for Column Piping Stress Analysis

- Creating temperature profiles for Column/Tower Piping systems

- Modeling of the Equipment

- Clip/Cleat Support Modeling from Towers

- Skirt Temperature Calculation

- Nozzle Load Qualification

- Practical Case Study

Module 19: Stress Analysis of Heat Exchanger Piping System (Duration: 1.5 hrs)

- To enroll for the heat exchanger piping stress analysis module, click here. This module explains

- Types of Heat Exchangers Used in the Oil and Gas Industries

- Temperature Profile of Heat Exchangers for Modeling

- Modeling the Heat Exchanger

- Nozzle Load Qualification

- Practical Case Study of a Shell and Tube Heat Exchanger Modeling

Module 20: A Roadmap to Pursue a Career in Pipeline Engineering (Duration: 1 hr)

- Join the course by clicking here. It covers:

- What is a Pipeline?

- What is Pipeline Engineering?

- Types of Pipeline Engineers, Their Roles and Responsibilities

- Opportunities for Pipeline Engineers

- Piping vs Pipeline; What are the Differences?

- Piping or Pipeline- Which Career Option is Better?

- How to become a Pipeline Engineer

Module 21: Steps for Pipeline Wall Thickness Calculation & Case Study (Duration: 1 hour)

- Click here to enroll in this module. This module covers:

- Need for Pipeline Thickness Calculation

- Pipeline Thickness Calculation Steps for Restrained and Unrestrained Pipelines

- Example of Pipeline Thickness Calculation for Aboveground Pipelines

- Buried Pipeline Thickness Calculation Case Study

- Additional Checks to satisfy pipeline thickness calculations

As mentioned earlier, new modules will be added frequently. So, keep visiting this post. Also, you can request any specific module by mentioning it in the comment section.