Long pipelines are often subjected to lateral and upheaval buckling. Both upheaval and lateral buckling can induce excessive bending stresses in the pipeline that may lead to pipeline failure. In January 2000, the 1.3 million liters of oil spill in Guanabara Bay, Brazil was initiated due to the lateral buckling phenomenon that caused the rupture of the offshore pipeline wall. Such consequences can be prevented, if the pipeline (both onshore and offshore) is designed to take care of the lateral and upheaval buckling phenomenon.

What are Lateral Buckling and Upheaval Buckling?

A pipeline traveling long distances transporting fluids under pressure and temperature is a slender structure. Both, temperature and internal pressure cause pipeline longitudinal expansion. Surface friction acts against this expansion restraining it which generates compression stresses in the pipeline wall that eventuates in buckling. There are two types of Buckling; Lateral Buckling and Upheaval Buckling.

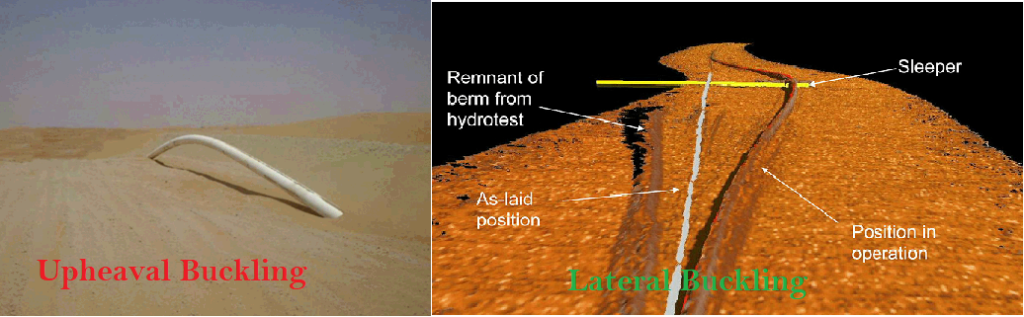

A surface-laid pipeline resting on the sand or seabed buckles laterally in the horizontal plane and this is called lateral buckling. On the other hand, a pipeline in a trench or sometimes buried pipeline undergoes buckling in the vertical plane, known as upheaval buckling. Both lateral buckling and upheaval buckling are highly sensitive in presence of local geometric imperfection.

As you might have gone through the previous article regarding the “Stress Analysis for Surface laid pipelines”, one of the Points of consideration during the analysis is the LATERAL / UPHEAVAL BUCKLING of the pipelines. The problem of upheaval / lateral buckling of the pipelines not only occurs naturally for the offshore (subsea) pipelines but also for the onshore pipelines at the Gathering and Injection lines of Oil and Gas production fields. In this article, we will explore the causes and the optimizations which could be implemented to avoid Upheaval / Lateral Buckling.

Causes of Lateral and Upheaval Buckling

When a pipeline is under operation at a temperature and pressure higher than ambient, it will try to expand. If the line is not free to expand, the pipe will develop an axial compressive force. If the force exerted by the pipe on the soil exceeds the vertical restraint against uplift movement created by the pipe’s weight, its bending stiffness, and the resistance of the soil cover, the pipe will tend to move upward, and considerable vertical displacement may occur. The pipeline response may then be unacceptable because of excessive plastic yield deformation. Upheaval buckling is hence a failure mode that has to be taken into account in the design of trenched and buried pipelines.

The buckling in the lateral direction is most probable when the pipelines are laid on a flat area or bund area (SABKHA area as it is also known in a desert) for sabkha areas and when it is not provided with sufficient lateral resistance. However, when the pipelines are buried in a normal trench, the soil constraints in the lateral direction are high due to a large mass of soil, and chances of lateral buckling are not present.

Upheaval Buckling Calculation

The calculation for the upheaval buckling is based on the technical paper “About Upheaval and Lateral buckling of embedded pipelines” by Dr. K. Peters (3R International Edition 2006) for the underground pipelines and flowlines.

Based on the calculations, the maximum allowable overbend angle, in 12m of pipe length (Cold bend length considered in Pipelines), along the pipeline route and other calculation parameters are specified in the applicable calculation reports and the drawings. The calculations can also be done with the development of programs in ‘Mathcad,’ or equivalent software based on Dr. K. Peter’s technical paper as mentioned above.

The calculations model is carried out in 2- phases,

Phase 1: Calculation is done based on the topographically surveyed pipeline corridor profile

Phase 2: The verification phase for the design model is based on the actual survey for the top of the pipe in the trench after lowering and before back-filling.

Lateral Buckling Resistance in SABKHA

A lateral force that required resisting lateral buckling can be calculated as per calculations mentioned in “Technical Paper about Upheaval & Lateral Buckling of Embedded Pipelines” while the allowable lateral bend angle can be also calculated in a similar way to the allowable over-bend angle as explained above with the difference being using the lateral soil resistance. However, in most cases, the change in direction will be exceeding any allowable lateral bend angle, and hence the lateral berm reinforcement at the change of direction shall be provided based on the study done by K. TERZAGHI in Theoretical Soil Mechanics.

Extra Soil Cover/Berm Reinforcement Material

In case of upheaval buckling analysis proves that an extra soil cover is required at any location on the pipeline route and also if berm reinforcement is required to resist lateral buckling, gatch material shall be used with the required stabilization and proper slope (1:2) so that it shall not be blown away by wind effect across pipeline design life. Gatch material shall be the same as the approved for pipeline berm stabilization.

Guidelines and Recommendations

Suitable notes shall be included in the alignment sheets and the applicable drawings to take care of the maximum allowable over-bend angle, during construction. The alignment sheets also shall indicate the minimum elastic bend radius.

The buried pipelines shall be laid in such a way that the profile of the pipeline is smooth and without steep direction change. To achieve this cutting and filling or other suitable methods shall be done during pipeline construction.

For a given design parameter, there are two primary options to control the upheaval buckling. The first one is to ensure that the change of angle is within the calculated maximum allowable overbend angle limit for the given soil cover. The second one is to increase the soil resistance to increase the allowable overbend angle. To increase the soil resistance, the most direct method is to increase the soil cover

If the profile is such that the angle exceeds this limit when routing the pipeline, then suitable grading shall be done to keep the change of angle within limits, or alternatively, the allowable angle can be increased by increasing soil cover

Based on upheaval buckling calculations, the maximum allowable over-bend angle per 12 m pipe length shall be defined while pipeline corridor profile grading shall be carried out to keep the change of angle within such allowable over-bend angle limits.

The calculations for normal terrain sections in sandy areas shall be carried out for an effective height of 1 meter. Though the total effective height would be considered 1.9 m with 1 m as the normal depth of cover and 0.9 m soil cover in lieu of a total berm height of 1.0 meters.

In addition to the requirement in item 9.4 above during corridor grading, the construction team shall survey the top of pipe elevations immediately after lowering at intervals of 100 meters and 10 meters intervals at a change of directions for a reasonable distance on both sides. This top of the pipe shall survey shall be carried out for the full entire pipeline in sections before backfilling and shall be completed for the full pipeline length and submitted to the stress engineer for upheaval buckling verification after laying.

Along with this document, the construction shall refer to relevant documents regarding stress analysis and the maximum allowed angle for field bends.

If two or more pipelines are laid in the same trench or are in the same corridor with the same grading, the maximum allowable overbend angle shall be the lowest of all the individual maximum overbend angles.

During the construction, the contractor shall give special attention to rough sections of the route identified in the alignment sheets and shall grade such rough sections suitably in line with the calculation results. This will make sure that during final buckling checks additional cover if required shall be minimum.

Conclusions

As per past experience, upheaval buckling would be expected at locations with less vertical resistance to axial compressive force in the pipeline sections such as straight sections between nearby road crossings, vertical/ horizontal overbend angles higher than allowed buckling angles, interface between sabkha and non- sabkha areas, at both sides of road crossings, etc.

Very well explained Jimmy.

Thanks

Thank you Ben.

Thanks for explaining it in detail. you have presented it nicely. However, while explaining Lateral buckling, you have mentioned ” A lateral force that required resisting lateral buckling can be calculated as per the Appendix provided at the end” . But I could not find any appendix attached here. Could you please upload the said appendix?

Hello Rajeev. Same has been updated

Hi Jimmy

Very well explained.

However, pt.6 under recommendations suggest to consider 1.9m cover for calculation. Right ??

1m cover should be conservative approach for the design life considering erosion etc.

Thank you sir for your suggestion.

Very well explained.

Is there a criteria for the allowable amount of lateral buckling amplitude or allowable axial stress?

If there is, please tell me what is it and a references or article that he has mentioned

, indicate which part of the source.

Thank you for your help.