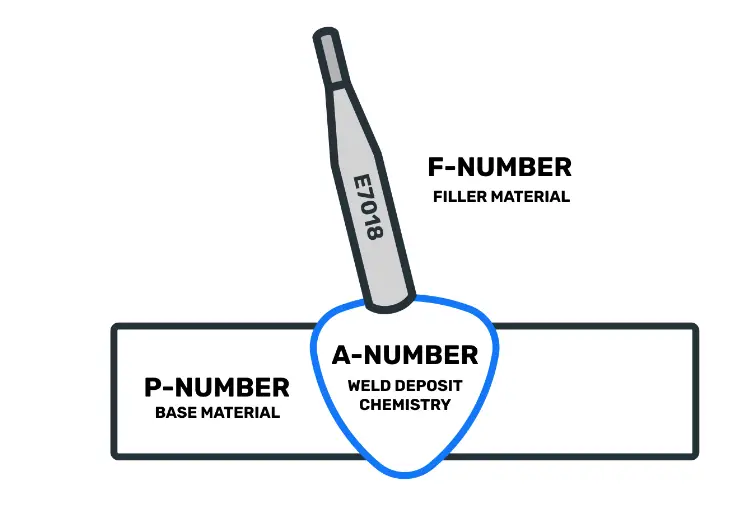

To ease welding procedure creation and welding procedure management, the ASME Weld Number tables provide a well-defined numbering system methodology. These numbers are assigned to the Weld base metals and filler metals. Grouping materials reduces the number of welding procedures and welder performance qualification tests for a wide range of materials. ASME Boiler and Pressure Vessel Code (ASME BPVC Section IX) has assigned a grouping scheme for base metals that consists of the P numbers and Group Numbers. Earlier there were ASME S Numbers that were removed by the code from the year 2009. Similarly, the filler metal grouping scheme consists of the F-Numbers and A-Numbers. Refer to Fig. 1, which clarifies what these numbers relate to.

What is the P Number in Welding?

Depending on the material characteristics like composition, weldability, brazeability, design consideration, heat treatment, and mechanical properties, ASME BPVC assigned P-Numbers to the base metals. The code assigned the same P-number for the materials with similar material characteristics. These are listed in Table QW/QB-422 of ASME. While changing the base metal from a qualified WPS to a new base metal, requalification or a new PQR is not required if the new base metal falls in the same P-Number.

These base metals are grouped by material and the assigned P-Numbers are constant for that specific material group. For example, the base metals of Low Carbon Steel or Carbon Manganese material fall in P-Number 1. The following table (Table-1) provides the P-number ranges for various metals and alloys.

| Sr. No. | Type of Steel, Metal, Alloy | P-Number |

| 1. | Carbon Steel (C-Mn ) | 1 |

| 2. | Low Alloy Steel (Cr-Mo Steels) | 4, 5A, 5B, 5C, 15E |

| 3. | Stainless Steels (Cr-Ni steels) | 8, 10H |

| 4. | Nickel & Ni-base alloys | 41 to 49 |

| 5. | Aluminum & Aluminum alloys | 21 to 26 |

| 6. | Copper & copper alloys | 31 to 35 |

| 7. | Titanium & titanium alloys | 51 to 53 |

| 8. | Zirconium & zirconium alloys | 61 and 62 |

From the ASME Sec IX table, QW/QB-422 can find the P-number of a specific grade of material, i.e. which material falls under which P-number and what is product form i.e. plate, forging, sheets, fittings, etc.

P-number is generally mentioned in WPS & PQR for procedure qualification and in WPQ for performance qualification.

What is the F-Number in Welding?

As the name suggests, F stands for Filler number. Depending on the composition, the microstructure of the material F-number is assigned to welding consumables i.e. filler wires, and electrodes to reduce the procedure and performance qualifications. F-number is generally mentioned in WPS & PQR for procedure qualification and in WPQ for performance qualification. The ASME Sec IX (QW-432 assigned the F-number on the basis of type of consumable, usability of consumable, metallurgical compatibility, heat treatment, and other mechanical properties. The same F no is assigned to carbon steel as well as stainless steel filler wires. For example. ER70S-6 & ER308 have the same F no. i.e. F no. 6. The following table (Table-2) provides the F-number ranges for various consumables as classified in ASME Section.

| Sr. No. | Type of Steel consumables | F-Number |

| 1. | Carbon Steel | 1 to 6 |

| 2. | Low Alloy Steel (Cr-Mo Steels) | 1 to 6 |

| 3. | Stainless Steels (Cr-Ni steels) | 5, 6 |

| 4. | Nickel & Ni-base alloys | 41 to 46 |

| 5. | Aluminum & Aluminium alloys | 21 to 26 |

| 6. | Copper & copper alloys | 31 to 37 |

| 7. | Titanium & titanium alloys | 51 to 56 |

| 8. | Zirconium & zirconium alloys | 61 |

| 9. | Hard-facing weld metal overlays | 71 and 72 |

From the ASME Sec IX, table QW-432 can find the F-number of specific consumables classified as per ASME Sec IIC. With the F-number there is a reduction of procedure and performance qualification as the same F-number of material does not require requalification.

From the ASME Sec IX, table QW-433 can be referred to for the welder performance qualification range. A snapshot is given below:

What is the A-Number in Welding?

As from the name, A stands for analysis. A-number is designated by ASME to weld metal deposition composition analysis to reduce the number of procedure qualifications in Welding. From the ASME Sec IX table QW-442 can be referred to for different A number is given to different groups of metals/alloys. A-number is generally mentioned in WPS & PQR. It is not essential for performance qualification i.e. not mentioned in WPQ.

Note that the A-Number gives the chemical composition of the weld metal in the “as-welded” state, not of the filler metal product in its raw form.

Click here to learn Welding Technology in detail.

Video Courses in Welding

To learn more about welding the following video courses you can refer to:

Thank you for sharing

In preparing Piping schedule unit rates (construction quantities), what’s recommended for material grouping for welding quantities? Whether to group materials according to P-number or F-number or combination between both of them?

If a combination will be used for material grouping, what’s the relation between both of P-number and F-number?

what will be the A Number when 2 dissimilar metals are welded

What’s the A-Number classification for Inconel UNS 625, 60 Ni-22Cr-9Mo-3.5 cb.

ASME IX QW-442 doesn’t figure this chemical composition on Table QW-442?