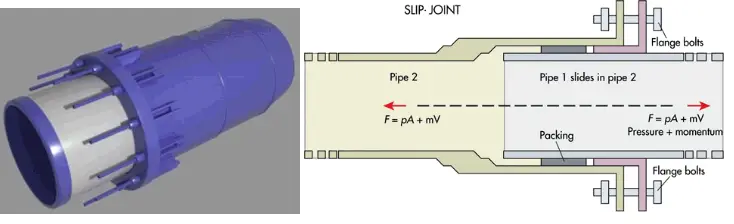

What is a Slip Joint?

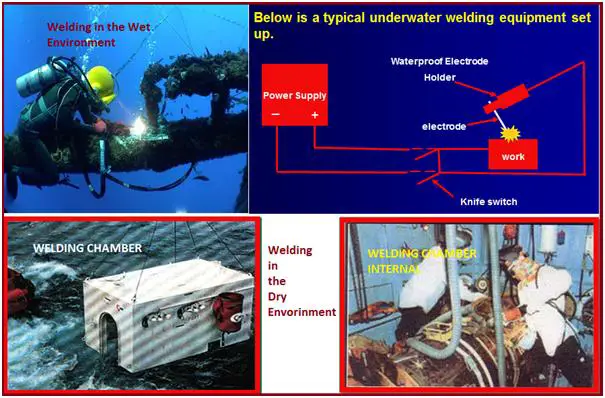

Slip Joints are mechanical joints that allow the contact surfaces of the pipes joined together to slip away from each other. When there is a large thermal movement of pipe and an expansion loop can not be provided due to other constraints, slip joints can be used to solve expansion stress problems. The slip joint has a rugged construction that makes it suitable for hostile environments, such as inside a ditch, underwater, or underground. However, as the sliding surfaces do not create perfect sealing, leakage may develop along the surface. This concern limits the use of slip joints in hazardous materials. To ensure the slip joint tightness, a considerable force needs to be maintained on the gasket or packing. This results in a fairly large internal friction force resisting the slipping movement. In some cases, this internal friction force is so huge that the joint simply losses its flexing capability. Slip joints are sometimes also known as slip-type expansion joints.

Types of Slip Joints

Depending on the modes of the sliding motion, slip joints are divided into two main types:

- Axial slip joint and

- Rotational slip joint.

Axial Slip Joint:

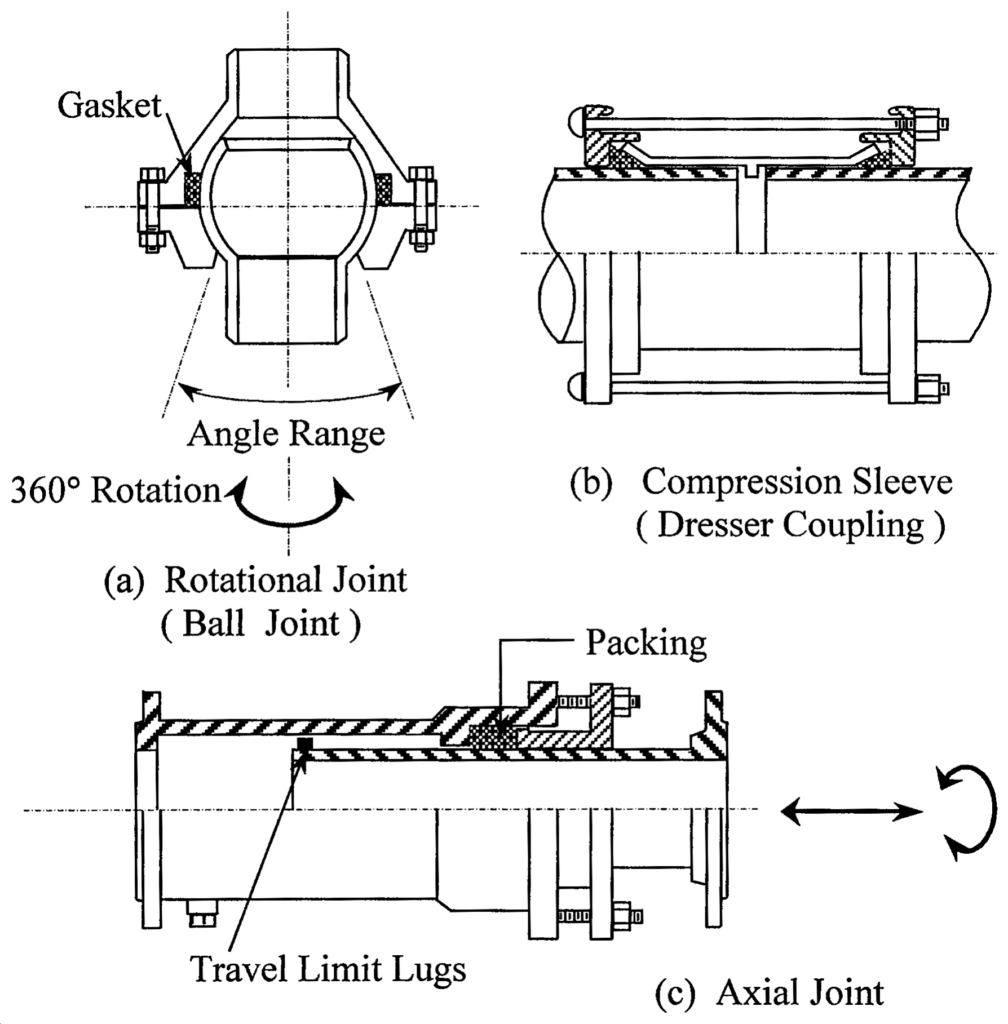

An axial slip joint allows the pipe to slide into it axially and at the same time allows the pipe to also rotate axially. Axial slip joints come in different styles. For low-pressure and temperature lines, the compression sleeve as shown in Fig. 1 (b) is used. When some moderate thermal expansion needs to be absorbed similar types of clamp-on couplings are commonly used. The compression sleeve, also known as Dresser Coupling, is very popular in water distribution systems where the temperature change is mainly due to climate change. For large movements at higher temperatures and pressures, an internally guided construction with a secure packing gland as shown in Fig. 1 (c) is used. All axial slip joints need main anchors to resist the pressure thrust force similar to bellow expansion joints.

To ensure column stability, properly located guides are needed. However, joints with internal guides are not required.

The internal friction force of an axial slip joint is very significant and should be taken into consideration in the design and analysis of piping and supports. Because an axial joint is normally installed to accommodate the expansion of a straight piping run, the anchor design load can be accurately estimated by the simple addition of the pressure thrust force plus the joint internal friction force plus the support external friction forces.

A computerized analysis normally requires for piping systems that are not entirely straight. The internal friction force can be simulated as the spring force of the axial flexible joint. Because the internal friction force is the product of movement and spring constant, it varies with the actual movement. The analysis may require a couple of iterations to match the spring force with the internal friction force provided by the manufacturer of the joint.

The axial slip joint can also accommodate the axial rotation of the pipe. Occasionally, a joint is specially constructed to accommodate only the axial rotation of the pipe. Because no axial movement is allowed, internal lugs can be installed to resist the pressure thrust force. Therefore, for this type of axial rotation joint, no anchor is needed. By strategically locating a couple of these types of rotational joints, the resulting piping system, much like a multi-hinged system, can accommodate very large movements.

Rotational Slip Joint:

A rotational slip joint is also known as a ball joint or a ball-and-socket joint. As shown in Fig. 1(a), the common type of ball joint is constructed with three main pieces. It has an inner ball-shaped adapter enclosed by a two-piece, dome-shaped housing. At the junction of the two housing pieces, the gasket is placed. As permitted by the opening of the outer housing, the joint can rock at a specific range. It is also capable of rotating 360 degrees axially. It is considered capable of rotating in any direction in a practical sense.

The rotational slip joint or ball joint is a very rugged component that is suitable for hostile environments, such as offshore and loading dock applications. It can sustain considerable abuse by piping and equipment operators. Again, to maintain the tightness of the joint, sufficient force has to be applied and maintained at the gasket or packing. This results in a considerable friction force creating a fairly large resisting moment against the rotation of the joint. The moment required to rotate the joint is called the break-off moment, whose magnitude is available from the manufacturer of the joint. This break-off moment can have a very significant effect on the flexibility of the piping and has to be taken into consideration in the design and analysis of the piping system.

Applications of Slip Joints

Slip joints are widely used in the wastewater plumbing industry. Also, they are popular in the piping industry for non-hazardous piping systems. Other applications of slip joints are:

- Slip joints are used in large structures for allowing independent motion of large components while enabling them to be joined. Bridges and overpasses frequently have slip joints that allow a deck to move relative to piers or abutments. The joints are constructed with elastomeric pads to permit motion or can use rollers on flat surfaces to allow the ends to move smoothly.

- Slip joints are used to adjust the length of the propeller shaft when demanded by the rear axle movements in the Automobile industry.

Very good information. A question, What can be used in buried pipes because they have settlements of 400 mm ?, where the pipe will deform and fail. It is for diesel fluid that its breakage will impact the environment. Maybe you have published an article on pipeline design studies and protection elements, I am thinking of absorbing combined angular and rotational movements of the pipeline. Thank you in advance for all your contributions to this specialization.

Hello a query. Have you published topics related to Inertia of Motors and Pumps of different models? How to calculate it theoretically and compare them with typical vendor values?

Hello Anup

Could you explain the above.

“Occasionally, a joint is specially constructed to accommodate only the axial rotation of the pipe. Because no axial movement is allowed, internal lugs can be installed to resist the pressure thrust force. Therefore, for this type of axial rotation joint, no anchor is needed”

Questions:

1. For a simple slip expansion joint, how could eliminate forces in anchors?

2. For example for 150 psig, 10″ steam pipe thrust forces + frictions are above 18,000 lbs.

Thanks

When installing a sigle slip joint in a heating piping system, I would like to know how to install the slip joint according to the pipe anchor, pipe guide installation location, fluid flow direction, or pipe extension direction.

It would be nice to see this “passionate” engineer reply to the queries.