Pipeline pigging is a very important activity during pipeline maintenance. It involves the use of pigs to clean, inspect, test, and check pipeline conditions of new or existing pipelines. Pig Launchers, Pig Receivers, and Pig Traps are essential components in the process of pipeline pigging. All of them are used for both liquid and gas pipelines. In the oil and gas industry operation, pig launchers, receivers, and traps are frequently used. They play a major role in maintaining the integrity, efficiency, and safety of pipelines that transport various fluids, including oil, natural gas, and liquids. In this article, we will learn about Pig launchers, Pig Receivers, and Pig Traps in detail.

Section 1: Pig Launchers

What is a Pig Launcher?

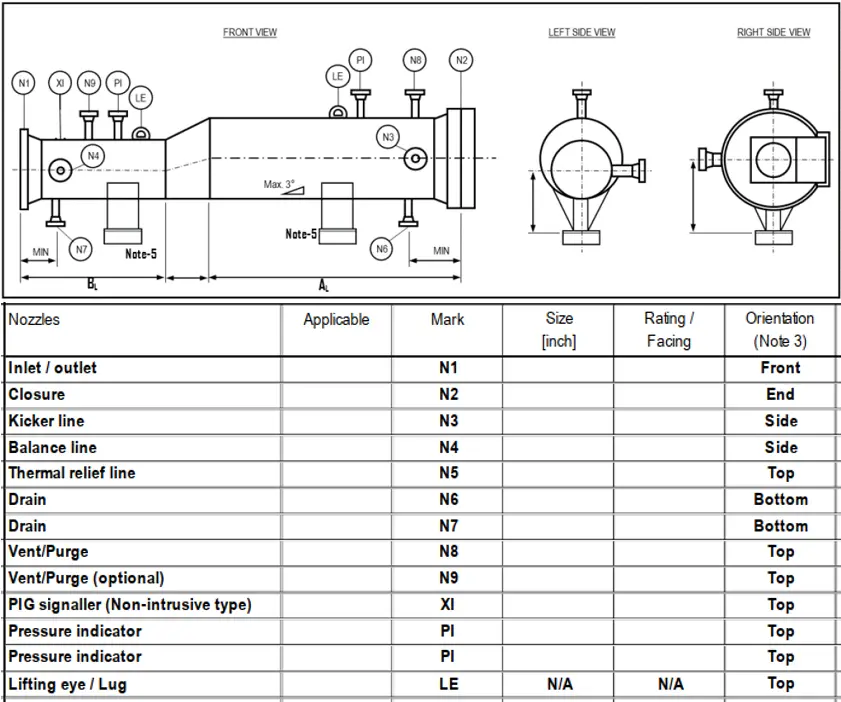

A pig launcher, located at the start of a pipeline is a device used to send a PIG through a pipeline. This is a Y-shaped funnel section of a pipeline where the PIG is propelled from the launcher barrel. Based on the pipeline size, the pig launcher size is decided. A pig launcher is also known as simply a launcher, launching station, or pig trap launcher. Pig launchers in onshore pipelines are usually horizontal but vertical installations of pig launchers are found on offshore platforms. Fig. 1 shows a typical schematic diagram of a pig launcher.

What does a pig launcher do?

The main functions of a pipeline pig launcher are:

- To safely introduce a pig into the pipeline.

- To provide a controlled environment for launching the pig into the pipeline.

- To isolate the section of the pipeline for pigging from the rest of the pipeline network.

What are the components of a pig launcher?

A typical pig launcher has the following components:

Major and Minor Barrel:

The Barrel part is the main body of the pig launcher. The major and minor barrels are both cylindrical vessels. The major barrel has a larger diameter and the minor barrel has a smaller diameter. The major barrel is an enlarged section of the barrel used for loading or retrieving pigs. The minor barrel is a section of the barrel between the pig trap valve and the reducer. They withstand the operating pressure and temperature of the pipeline. The barrel has several key components:

- Barrel Valve: At the inlet end of the barrel, the barrel valve is located. The main function of the valve is to allow the pig to be loaded into the launcher and also to seal the pipeline when the pig launcher is not in use.

- Nozzle: The nozzle is the connection point between the launcher and the pipeline. It’s where the pig is inserted into the launcher.

- Pressure Relief Device: A safety device that prevents over-pressurization of the barrel. It can be a rupture disc or relief valve.

Other components of a pig launcher include the following items:

- Reducer: An eccentric reducer between the major and minor barrel.

- Pig Signaller: Pig signallers are devices that monitor the passage of the pig through the launcher. They provide valuable information about the pig’s location and movement within the pipeline.

- Launching Mechanism: The launching mechanism is responsible for propelling the pig into the pipeline. It can be either pneumatic or hydraulic. The choice of launching mechanism depends on factors such as pipeline size, operating pressure, and pig size.

- End closure: A quick opening end closure welded to the major barrel allowing the insertion and removal of pigs

- Kicker line connection (A kicker line connects the major barrel with the bypass line to enable diversion of the fluid through the barrel to launch or receive a pig.), Kicker line valve.

- Balancing line connection (A balance line connects the front of the pig trap (minor barrel) to the kicker line).

- Closure Mechanism: The closure mechanism of a Pig Launcher is responsible for sealing the barrel during normal pipeline operation and for safely launching the pig.

- Pressure gauge connection

- Utility connections

- Vent and drain connection, drain valve

- Relief Lines

How Do PIG Launchers Work?

The operation or working of a Pig Launcher may vary slightly depending on the specific application. However, the major pig launcher working philosophy involves the following steps:

Step 1: Ensure that the isolation and kicker valves are closed.

Step 2: Open the drain valve and vent valve to fully drain the pipeline.

Step 3: Open the trap door.

Step 4: Load the pig with its nose in contact with the reducer

Step 5: Seal the closure and trap door.

Step 6: Close the drain valve.

Step 7: Open the kicker valve and fill the trap.

Step 8: Once full, close the vent valve.

Step 9: Open the isolation valve and the pig is ready to launch

Step 10: Gradually close the main valve and build the required pressure in the pipeline launcher by increasing the flow through the kicker line.

Step 11: At a certain pressure, the PIG leaves the pig trap and enters the pipeline

Step 12: Once the PIG leaves the launcher, fully open the mainline valve, and close the isolation and kicker valve.

Step 13: Monitor the pig’s progress using pig signalers and instrumentation.

Section 2: Pig Receivers

What is a Pipeline Receiver?

A pig receiver is located at the end of the pipeline. It is a cylindrical container to receive a pipeline pig out of the pipeline. Pipeline pig receivers are also known as Pig Trap Receiver, Receiving Station, or simply Receiver. Pig receivers are mostly horizontal in both onshore as well as offshore installations. Fig. 2 below provides a typical image of the Pig launcher and receiver station.

What is the Function of a Pipeline Receiver?

The primary functions of a pig receiver are:

- To safely receive and capture the pig after it has traveled through the pipeline.

- To isolate the section of the pipeline for pigging from the rest of the pipeline network.

- To allow for the safe removal of the pig after inspection, maintenance, and for further processing.

Components of a Pig Receiver

A pig receiver also has components similar to a pig launcher.

Working of a Pig Receiver

The working steps for a pig receiver are mentioned below:

Step 1: The barrel valve is closed to isolate the receiver from the rest of the pipeline.

Step 2: As the pig enters the receiver, it is captured and held in the trap.

Step 3: The pressure within the receiver is safely released to ensure that it can be safely opened.

Step 4: The closure mechanism is opened to access the pig for inspection or maintenance.

Step 5: The pig is carefully removed from the pig receiver using specialized equipment.

Pig Launcher vs. Pig Receiver

A pig launcher and a pig receiver are both essential components of a pipeline pigging system, but they serve different purposes and have different designs.

A pig launcher is the access point where the pig is inserted into the pipeline. It is typically a large vessel that is connected to the pipeline and is designed to handle the high pressures and flow rates of the pipeline. The launcher is equipped with a closure mechanism, such as a valve or a quick opening closure (QOC), that allows the pig to be inserted into the pipeline and launched downstream.

A pig receiver, on the other hand, is the access point where the pig is removed from the pipeline. It is also a large vessel that is connected to the pipeline and is designed to handle the high pressures and flow rates of the pipeline. The receiver is equipped with a closure mechanism, such as a valve or a QOC, that allows the pig to be captured and removed from the pipeline.

The key differences between a pig launcher and a pig receiver are:

- The direction of flow: A pig launcher is where the pig is inserted into the pipeline, while a pig receiver is where the pig is removed from the pipeline.

- Closure mechanism: Both the pig launcher and pig receiver have closure mechanisms, but they serve different purposes. The launcher closure mechanism allows the pig to be launched into the pipeline, while the receiver closure mechanism captures and removes the pig from the pipeline.

- Location: Pig launchers and receivers are typically located at opposite ends of the pipeline. The launcher is located at the upstream end of the pipeline, while the receiver is located at the downstream end of the pipeline.

Overall, the pig launcher and pig receiver are both essential components of a pipeline pigging system, and their proper design, installation, and operation are critical to ensure the safe and efficient cleaning, inspection, and maintenance of pipelines.

Section 3- Pig Trap System

What is a Pig Trap System?

A pig trap system is defined as an ancillary item of pipeline equipment, with associated pipework and valves, for introducing a pig into a pipeline or removing a pig from a pipeline. Pipeline Pig Traps are a critical component of both Pig Launchers and Pig Receivers. Safely capture and hold the pig after it enters the launcher or receiver. Pig Traps in pig receiving stations prevent the pig from re-entering the pipeline and allow for its easy removal.

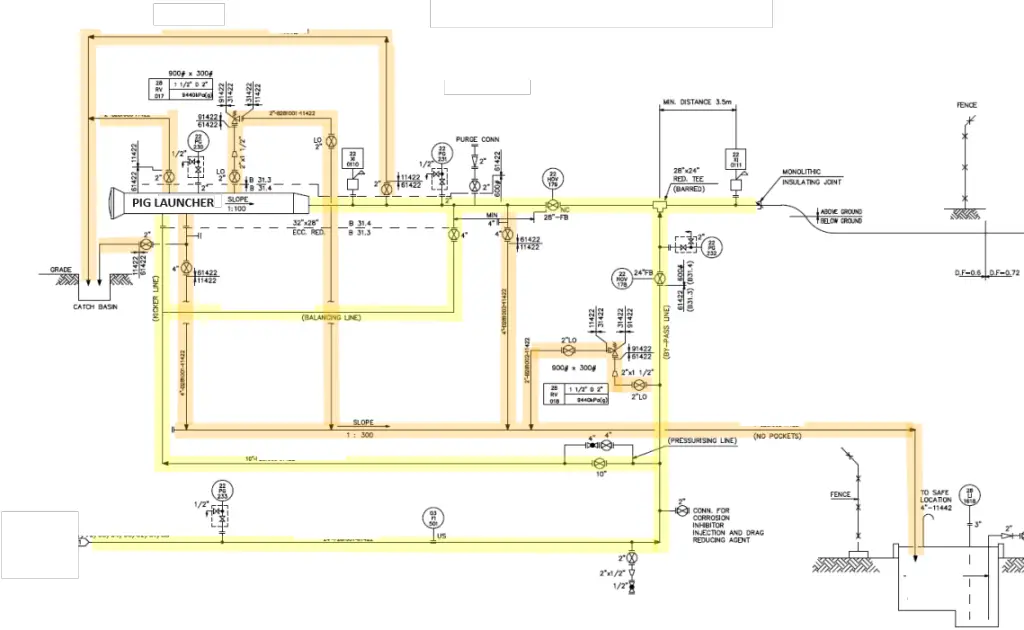

Both pig launching stations and pig receiving stations are known as pig trap systems. Fig. 3 below shows a typical P&ID showing the arrangement of Pig launcher system will all connected pipe parts.

Types of PIG Traps

Pig traps are categorized into two classes; permanent pig traps and temporary pig traps.

Design Considerations for PIG Trap Systems

The design for pig trap systems varies from project to project and onshore to offshore installations. Some of the guidelines that can be considered for designing horizontal permanent pig trap systems are listed below:

- Pig trap systems are designed based on ASME B31.4 for liquid services and ASME B31.8 for gas services.

- Normally the pig trap will have flanged nozzles unless welded nozzles are specified to minimize flanged joints for leak path reduction.

- Barrel lengths are decided based on the type of pigs used.

- The reducer between the major and minor barrel shall be eccentric with a flat side at the bottom to enable the bottom of the entire barrel at the same level.

- The barrel is sloped down towards the end closure or towards the pipeline to a maximum of 3° to improve the draining of liquids from the barrel.

- The drain nozzle at either end shall be suitably located to ensure the maximum possible draining of the pig trap barrels.

- The minimum nominal diameter of all pipework shall be DN 50 (NPS 2).

- A kicker line connects the major barrel with the bypass line to enable the diversion of the fluid through the barrel to launch or receive a pig.

- For a launcher, the kicker line shall be connected to the major barrel as close as possible to the end closure, and for a receiver as close as possible to the reducer.

- For bi-directional pig traps, a single kicker line may be located as close as possible to the end closure.

- A balanced line connects the front of the pig trap (minor barrel) to the kicker line. A balance line shall be provided on launchers to enable filling and pressurizing of the barrel on both sides of the pig. Whereas, A balance line shall be provided on receivers to prevent any possible pressure differential across a received pig.

Good day! executant work!

Hello Mohamed,hope you are well in this month of ramdan

please is pig trap stay under pressur or empty in gas compressor station when it is in service.

Best regards