Process Industries uses various types of equipment for different process reasons. The main purpose of this presentation is to discuss the basic aspects related to fixing an appropriate location for the piping design of static equipment. Static equipment generally found in process plants are as follows:

- Fired Heaters

- Reactors

- Exchangers

- Air-cooled Heat Exchangers

- Drums

- Towers

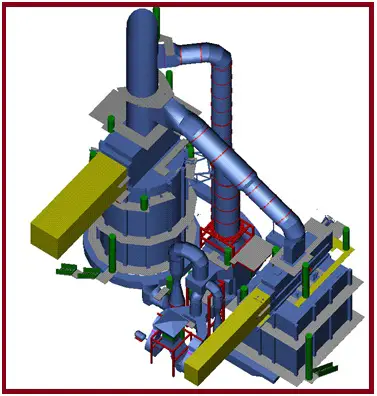

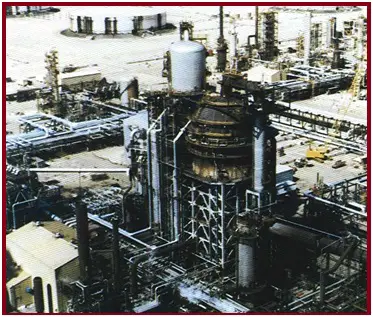

Fixing the Location of Fired Heaters

- The fired heater shall be located in the upwind direction or at least crosswind from sources of hydrocarbon leaks.

- The minimum distance is required between the fired heater and the fractionating tower and reactor.

- Provide tube removal/maintenance space within battery limits. Crane access may be necessary, especially for vertical tubes.

- Provide space for removal/maintenance of burners, soot blowers, and convection sections.

- Knockout drums for fuel gas supply to fired heaters shall be located as close as possible.

Fixing the Location of Reactors

- The location shall be as close as possible to Fired Heaters so that piping is short and simple.

- Reactors shall be located for ease of access during catalyst unloading and loading operations.

- Space shall be allowed for cranes and storage of spent and new catalysts.

- A separate structure with the platform is required for catalyst loading and unloading.

- Space shall be allowed for TW- removal & maintenance.

Fixing the Location of Exchangers

- Locate exchangers at grade unless the elevated location is required by the Client.

- Shell and tube exchangers shall be located with channel end away from pipe ways to facilitate tube bundle removal.

- For exchangers under drums or unit structures, where ever possible the channel end shall be clear of overhead structures for the handling of the channel end by mobile equipment.

- Heat exchangers containing flammable liquids above 260 C, or their auto-ignition temperature (if lower), shall not be located beneath other equipment.

- Exchangers shall be located close to the associated equipment and pipe rack, so that the piping is short, but has adequate flexibility.

Fixing the Location of Air-cooled Exchangers

- Process equipment shall not be located above or below air-cooled heat exchangers.

- Locate above the unit pipe rack.

- Can’t locate where the discharge air from one exchanger can become the incoming air to another exchanger.

- Provide crane access to air-cooled heat exchangers for maintenance.

- The distance between the air condenser outlet and the receiver shall be minimized.

Fixing the Location of Drums

- Drums are located within a processing unit either adjacent to related equipment or as a standalone operation

- Should be positioned to facilitate an orderly and economic piping interconnection.

- Generally, drums are located on either side of a central pipe rack serviced by an auxiliary road for maintenance access

- Drums are generally located at all levels of enclosed or open-sided structures.

You may be interested in

Static Equipments used in Process Piping Industry

Nozzle Loading of Various Equipments and means for reducing them

Considerations for Equipment and Piping Layout of Air Cooled Heat Exchanger Piping

A Brief Presentation on Storage Tanks

Vendor Offer Review, TBE and Vendor Drawing Review

Construction and Maintenance of Fired heaters

Thank you for this post.

Just wanted to add that there is a new fired heater software called Heater560, which is very easy to use and allows you to design API Fired Heaters fater than ever before.