The knowledge of both stress and strain is very important in design as their relationship to each other defines the mechanical properties of a material. But which comes first between Stress and Strain is really a very confusing question to many. Whenever a force is applied to a body, Stress, and Strain both are believed to occur. But which one comes first? Let’s try to understand the same from the basics.

What is Stress?

Whenever a force is applied to a body from outside (external forces), its first tendency is to resist that force. So, the body will generate an internal resistance force that will resist the external force to create any damage (deformation). This internal resistance force per unit area (cross-sectional area on which Force acts) is called stress and is denoted by

Stress (Ϭ)= -F/A

What is Strain?

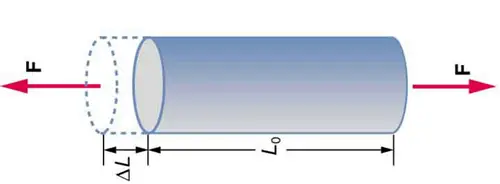

Refer to the image below (Fig. 1). When the pipe is pulled using a Force F, the pipe elongates i.e deformed from its original length L0

The strain is the geometric quantity that measures the deformation of the above pipe. The ratio of this elongation (∆L, change in length) with respect to the original length (L0) is known as Strain and expressed as

Strain (δ) =∆L/L0

Which comes first: Strain or Stress?

From the above paragraphs, it is clear that for the generation of Stress or Strain, the main contributing factor is the Force, F. So force is the cause. And Once force is applied, it tries to deform the body instantaneously. So obviously, deformation or change in length will come first. This deformation can be measured using Strain gauges. Because once deformation or damage tends to appear, then only internal resistance force will be created and will try to resist that change. So, there has to be deformation first for the creation of stress. Actually, stress is a derived value, it’s only a mathematical term. You can not see or measure it. Similar to Strain gauges there is no instrument where stress can be measured. It is always calculated.

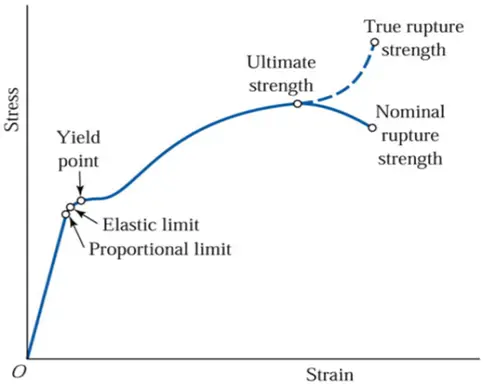

The same philosophy can be easily understood from the Stress-Strain curve, as well. For generating a curve, the standard practice is to keep the independent parameter on X-Axis and the Dependent one on Y-Axis. Now, look at the image below (Fig. 2) showing the stress-strain curve.

The Strain is on the X-axis and Stress is on the Y-Axis. Hence, It is clear that Stress is dependent on Strain.

Again, the above definitions of Stress and Strain are provided based on two assumptions.

- The cross-sectional area (A) is considered constant throughout.

- The original length (L0) is considered constant.

So, Now we defined the above; Stress =Force/Area and Strain=Change in length/original length.

According to the above assumption, both Area and Original Length is constant. So the above Stress-Strain curve can be considered as a Force vs deformation curve. Which means Force is creating the deformation.

So from the above discussions, it is clear that Strain comes first, and then Stress is generated.

Few more useful resources for you..

10 Differences between Pressure and Stress

Basics of Pipe Stress Analysis

Piping Stress Analysis using Caesar II

Piping Stress Analysis using Start-Prof

Piping Design and Layout Basics

Piping Materials Basics

I like your blogs

Thanks so clarifying this. It’s highly appreciated. I will like to read more on your post especially on shear force and bending moments.

With no external force (F in Fig. 1) no elongation happens in the pipe and therefore no strain and no stress.

Force is first, stress and strain are depending and simultaneous, connected by the E modulus.

Sir when force is creating the deformation then how strain comes first. Sorry i m not getting well. Your topic is so enloberating but i get confused in last line that when force crates deformation then how the strain comes first.

Firstly i applied force applied on a job per unit area it becomes the stress and after that change in length occures so how.

yes I too feel the same.

Good work.

It seems that you are the ex student of made-easy.And you were the student of Mondale sir too.

Its is really confusing . to my understanding whenever force applied to an object or material , their will be stress (resisting force) developed . I hope for all magnitude of force ,deformation will not occur but stress will be their which will resist from deformation. when the magnitude of force is exceeding gradually their is deformation in the form of yielding , necking etc.

sir in case of stone ,when we applied load , it will not deform then what we say that stress is already exist sir give a best example to understand this question which comes first