The term TBE i.e, Technical Bid Evaluation is well-known to all piping engineers. Whenever any piping item is purchased from a vendor, before placing the final order, it is required to check the technical requirements of the items. This will ensure that the item is meeting all technical requirements for which the item is intended.

In a similar way, all spring hanger (both variable and constant) quotations received from spring hanger vendors (vendor drawings) are checked thoroughly. The following write-up will provide a guideline about the major points which must be checked for the Spring hangers to work properly.

Spring hot load, Cold load, Spring rate, Variability

It is intended that the vendor spring datasheet should meet the client’s spring hanger datasheet exactly. If at the start of the project, the spring vendor is decided and the offer is taken from that decided vendor then all the above-mentioned data will match exactly.

However sometimes it is not possible to determine the spring vendor at the start of the project and all springs are designed based on any standard spring vendor (such as the Lisega, Carpentar & Patterson, Piping Technology and Products, Anvil, or any other) and when the final order is placed from some other vendor the data varies. So in this context, the Piping Engineer (Materials engineer or Pipe Stress engineer) should check the acceptability of each Spring hanger.

Normal practice is to match the hot load exactly as that is the load the spring hanger will carry during operation. And because of different spring rates depending on the vendor, the cold load will vary. However, it is required to match the Spring rate as nearer as possible So the Cold load will also be nearer to the client datasheet value. A mismatch of roughly +/-5% is acceptable for Static equipment and Centrifugal Pump connected lines. For highly strain sensitive critical rotary equipment like Steam turbine, Centrifugal compressor, etc connected lines the stress engineer should input the exact offer values and verify the stress results.

In addition to the above, it is to be checked that the hot load and cold load lie within the range provided by the catalog. The variability is also to be checked and to be kept within 25% (10% for rotary equipment connected lines).

Overall Spring Height with all attachments

One of the major points which sometimes missed out for checking is Elevation or overall spring height (In certain cases Spring casing diameter). One should critically check the actual space available and the space required for placing the spring hanger. If the overall height with all attachments is more than the available space in the construction site then the Spring hanger needs to be rejected or the vendor is required to provide a separate revised offer for that spring. During the initial design phase, it is better to keep some extra space for the spring hanger assembly as that can be later adjusted after receipt of the actual vendor offer by adjusting rod length for top-mounted springs or by adjusting dummy length or shoe height for bottom-mounted springs.

Attachment Materials

The spring hanger (top-mounted Springs) attachments that will be directly in contact with the pipe like lug, clamp, etc should of similar material as that of the pipe. This must be ensured while doing TBE.

PTFE or SS plate requirements

Sometimes for bottom-mounted spring hangers PTFE or SS plate is required above the spring load flanges. While performing TBE it is to be checked whether the PTFE/ SS plate of proper dimension is provided by the vendor or not as well as provided as a loose item or attached with a load flange. The height of these items is to be included in over-spring height while designing or making datasheets.

Other Miscellaneous data

Some other miscellaneous data are required to be checked which are listed below:

- Whether the items supplied are corrosion-resistant or not?

- Whether Spring coil is coated or not?

- Whether all testing requirements are met?

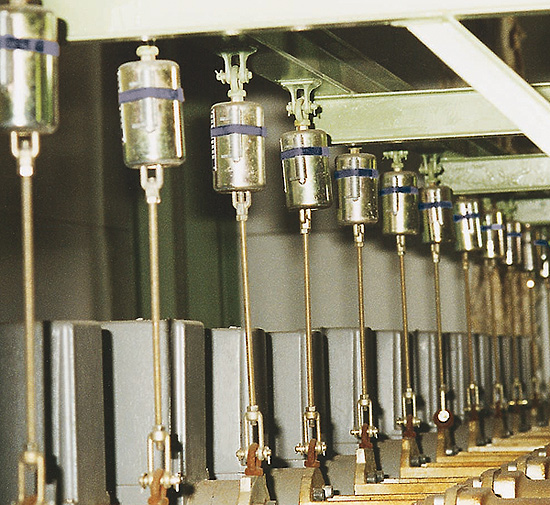

- The vendor should properly indicate the cold (Blue mark) and hot loads (Red mark) properly.

- Whether travel stoppers/preset pins are properly installed or not?

- Whether all items are painted as per governing specifications or not?

Few more useful Resources for you…

Technical and General requirements for Spring Hangers while purchasing.

TBE of vendor Spring hangers: Main points to consider before placing an order

Spring hangers: Common Interview Questions with Answers

Spring hanger selection and design guidelines for a Piping engineer using Caesar II

Basics of Pipe Stress Analysis

22 Mar2015 – Spring Hanger Procurement article. “Whether all items are painted as per gorerning or not?”

What is this (gorerning) word? Did you mean ‘governing’?