ASME B16.47 is an American standard for large-diameter steel flanges. This standard covers the design of flanges from NPS 26 to NPS 60. For lower sizes i.e., up to NPS 24, ASME B16.5 has to be referred. ASME B16.47 provides pressure-temperature ratings, materials, dimensions, tolerances, marking, and testing for pipe flanges with rating class designations 75, 150, 300, 400, 600, and 900. The Standard also includes the requirements and recommendations regarding flange bolting, flange gaskets, and flange joints.

What is ASME B16.47 Flange Series?

The ASME B16.47 standard provides the use of two types of flange series.

- Series A flanges and

- Series B flanges.

Series A specifies flange dimensions for general-use flanges whereas Series B specifies flange dimensions for compact flanges. Series A flanges have larger bolt circle diameters than Series B flanges.

This is to be noted that Series A and Series B flanges are not interchangeable. So, the user must take care of the compatibility issues that may arise by mistake. In most cases, flanged valves, equipment bolted between flanges, and flanged equipment are compatible with only one series of these flanges.

Difference between ASME B16.47 Series A and Series B Flanges

The major differences between Series A and Series B can be decided based on the following parameters:

1. Physical Attributes:

Series A Flanges:

- Thickness and Weight: Series A flanges are thicker and heavier compared to Series B flanges. This increased thickness provides greater strength and durability.

- Bolt Holes: They have larger diameter bolt holes, which generally require larger fasteners.

- Bolt Circle Diameter: Series A flanges have a larger bolt circle diameter, which means they have fewer but larger fasteners.

Series B Flanges:

- Thickness and Weight: These flanges are thinner and lighter than Series A flanges, making them less robust.

- Bolt Holes: Series B flanges feature smaller diameter bolt holes that necessitate the use of smaller fasteners.

- Bolt Circle Diameter: They have a smaller bolt circle diameter, which results in more bolt holes and generally requires smaller bolting hardware.

2. Strength and Load Handling:

Series A Flanges:

Strength: Due to their increased thickness and material weight, Series A flanges are stronger and can handle more external loading compared to Series B flanges.

Series B Flanges:

Strength: These are relatively weaker and can handle less external loading due to their reduced thickness and lighter weight.

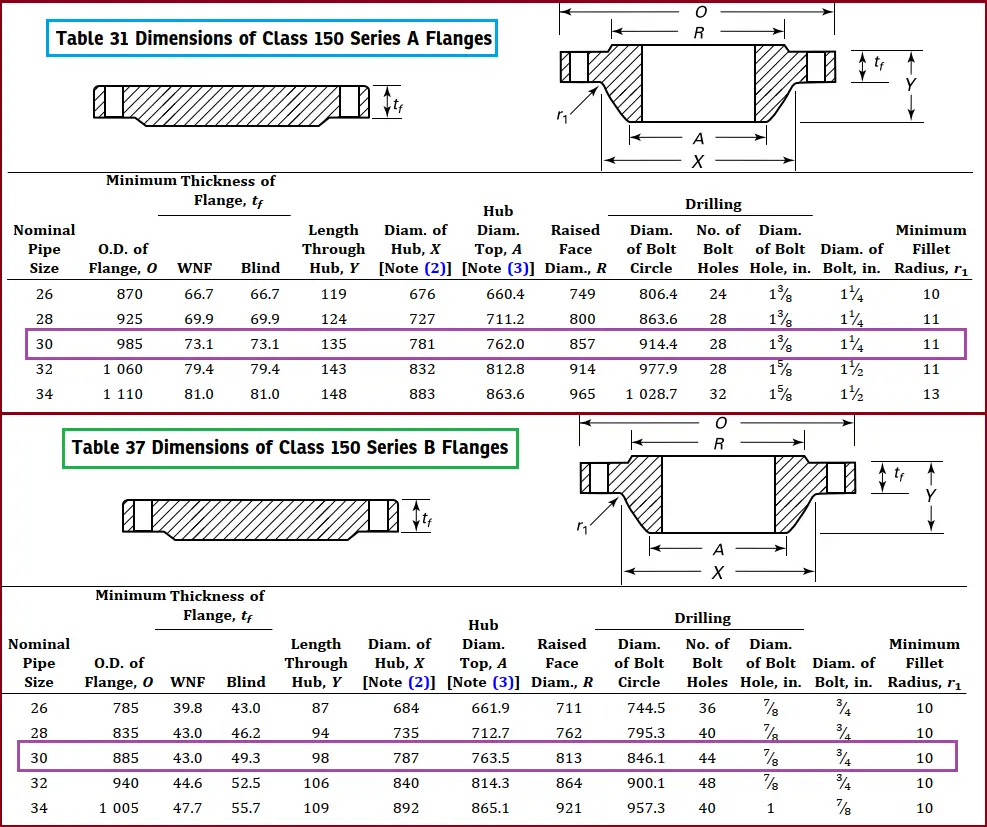

Refer to Fig. 1 below, which highlights some of the differences:

3. Fasteners and Installation:

Series A Flanges:

Fasteners: The quantity of fasteners is fewer but larger fasteners are required. This generally leads to a larger bolt circle diameter.

Series B Flanges:

Fasteners: They require more quantities but smaller fasteners. This results in a smaller bolt circle diameter.

4. Flange Types and Standards:

Series A Flanges:

- Types: Includes weld neck flanges, blind flanges, and ring-type joint (RTJ) flanges from Class 300 through Class 900.

- Application: Series A flanges are generally used in new pipeline projects or equipment installations.

Series B Flanges:

- Types: Also includes weld neck flanges and blind flanges but does not include RTJ flanges in the standard.

- Application: More commonly used for refurbishment or replacement jobs in existing pipelines.

5. Cost:

Series A Flanges:

Price: Typically more expensive due to the higher steel content and thicker design. The increased material weight contributes to higher costs.

Series B Flanges:

Price: Generally less costly because of the reduced steel weight and thinner design, which results in lower material and manufacturing costs.

6. Compatibility and Usage:

Series A Flanges:

- Compatibility: Not compatible with Series B flanges in terms of bolting due to differences in bolt-hole sizes and patterns.

- Typical Uses: Industrial connectors such as valves, pumps, and pipeline separations.

Series B Flanges:

- Compatibility: Not compatible with Series A flanges for the same reasons mentioned above.

- Typical Uses: Often used in pipeline applications where cost-efficiency and weight considerations are more critical.

The following table provides the major differences between ASME B16.47 Series A and Series B flanges.

| Sr. No | Parameter | ASME B16.47 Series A Flanges | ASME B16.47 Series B Flanges |

| 1 | Origin | Earlier Series A flanges were known as MSS SP 44 flanges. | These flanges were known as API 605 flanges. |

| 2 | Dimension | Flange Outer diameter, Bolt Circle Diameter, Flange Thickness, Bolt Diameter, etc. are larger for Series A Flanges for the same pressure rating class. | B16.47 Series B flanges are compact as compared to Series A flanges. |

| 3 | Strength | ASME B16.47 Series A flanges are comparatively stronger. Hence, can handle more external loading before leakage. | Load bearing for the same pressure class is relatively less. |

| 4 | Fastener Requirement | The quality requirement is less but bigger size. For example, as seen in Fig. 1, a 30-inch class 150 series A flange needs 28 bolts of 1-1/4 inch diameter. | The quantity of fasteners is more. For example, a 30-inch class 150 Series B flange requires 44 bolts with a diameter of 3/4 inch. |

| 5 | Ring type joint Types | Available from Class 300 through Class 900 | Does not exist. |

| 6 | Pressure Class 75 | Not available for series A flanges | Available for Series B flanges |

| 7 | Flange Weight | The weight of ASME B16.47, series A flanges is more. So, they exert more load on piping supports. | Weight is comparatively less |

| 8 | Cost | More expensive. | cheaper. |

| 9 | Industry Use | More frequently used. Used for critical applications. | Less frequently used. Normally used for non-critical applications. |

Dimensional Comparison for ASME B16.47 Series A and Series B Flanges

Refer to Fig. 2, which shows the comparative dimensions for 30″ (150 class) Series A and Series B ASME B16.47 flanges.

What is the flange standard for flanges above 60″ sizes?

Ans: Flanges above 60″ sizes are usually designed based on the AWWA C207 standards, or they are specifically designed by manufacturers considering the specific requirements of the users/purchasers.

Few other useful differences for you.

Differences between ASME B 31.4 and ASME B 31.8

13 major differences between Seamless and Welded Pipe

10 Differences between Pressure and Stress

Difference between Tee and Barred Tee

Difference between Stub-in and Stub-on Piping Connection

Difference between Centrifugal and Reciprocating Compressor

Difference between PDMS and PDS

Difference between Piping and Pipeline

Difference between Pipe and Tube

Difference between Primary load and Secondary load

Difference between Caesar II and Start-Prof

Difference between API and ANSI Pump

Appreciate what you”re doing . Thanks a lot.

Excellent work keep it up

Excellent

Thank you for sharing the difference for ease of selection of flange class.

Thank you so much

for nominal sizes greater than 60″, which class is followed?

i have pipe diameter ranging upto 125″

need to order the blind flanges accordingly.