Drilling rigs are massive structural equipment that is used to drill water wells, oil wells, or natural gas extraction wells. By rotating a bit, a hole is drilled using a downward force.

Types of Reservoir

- Sandstone

- Limestone

Main Trapping Mechanism

- Anticline

- Fault

- Stratigraphic

Types of Drilling Rigs

Drilling Rigs are classified as follows

- Land Rigs

- Submersible Rigs

- Jack-up Rigs

- Platform Rigs

- Semi-submersible Rigs

- Drill Ship Rigs

Based on the configuration of the drilling rigs, they are grouped into Light, Medium, Heavy and Ultraheavy groups. The capabilities of such drilling rigs are tabulated below:

| Duty | Depth | |

| Feet | Meters | |

| Light | 3000 – 5000 | 1000 – 1500 |

| Medium | 4000 – 10,000 | 1200 – 3000 |

| Heavy | 12,000 – 16,000 | 3500 – 5000 |

| Ultraheavy | 18,000 – 25,000 | 5500 – 7500 |

Land Drilling Rigs

The features of Land drilling rigs are

- They typically come in light, medium, or heavy configuration

- Is moved using heavy trucks and cranes

- Small rigs may only drill to a few thousand feet.

- But larger ones are capable of 12,000 and more

Submersible Drilling Rigs

The features of Submersible Drilling Rigs are

- Tend to drill in fairly shallow water. They flood the legs with water and submerge them.

- Some of the rigs are above water, and crews drill from that location.

- Swamp type, river, and inland bay areas

- Typical water depths are 20 feet

Jack-up Drilling Rigs

The features of Jack-up Drilling Rigs are

- Have lattice legs that can be hoisted and lowered at will.

- They are hoisted and the rig is either towed or transported by ship.

- When in location, the legs are lowered to the sea bed.

- Jack-up rigs can drill in water depths up to 400ft

Platform Drilling Rigs

The features of Platform Drilling Rigs are

- Are immobile once built.

- However, they drill several wells from one location.

- They can be tender assisted.

- Three types of Platform are:

- 1-Steel Jacket, 2- Caisson Type 3- Concrete Gravity

Semi-submersible Drilling Rigs

The features of semi-submersible drilling rigs are

- Has hollow legs and pontoons. Like the submersible, the legs are also flooded

- However, anchors and/or Thrusters and Positioners keep the rig in position,

- When thrusters are used, it is called Dynamic Positioning (computer controlled),

Drill Ship

- Are self-propelled, floating offshore drill units

- A template that has holes drilled though it is fitted to the sea bed

Rig Systems

- The Power System

- The Rotating System

- The Hoisting System

- The Circulating System

- The Blowouts Prevention System

Power System

Subdivided into two parts

- Power Generation

- Power Transmission

- Electrical Transmission

- Mechanical Transmission

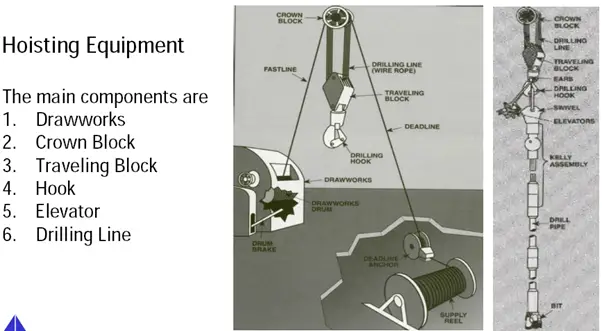

Hoisting System

- The supporting structure

- The hoisting equipment

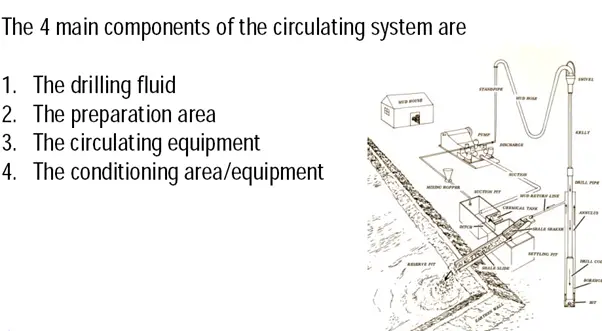

Circulating System

Drilling Fluid

- Transports cutting out of the hole

- Supports well-bore wall

- Cools and lubricates bit and drill stem

Fluid Composition

- Water-based drilling fluid

- Oil-based mud

- Air or gas-based drilling fluids

Blowouts Prevention System

The BOP system has two functions

- To seal the wellbore on a kick

- To maintain sufficient back pressure

BOP used in

- Land

- Submersible

- Jack-up

- Platform

Sub Sea BOP used in

- Semi-submersible

- Drill Ship.

Casing Design

Hydrostatic Pressure- Hydrostatic Pressure is defined as the pressure exerted by a column of fluid this pressure is a function of average fluid density and the vertical height or depth of the fluid column.

Mathematically it is expressed as:

HP=g. ρf.D

- HP = Hydrostatic pressure. (psi),

- g = Gravitational acceleration,

- ρf = Average fluid density. (ppg),

- D = True vertical depth. (ft)

Pore Pressure- Pore Pressure is defined as the pressure acting on the fluids in the pore spaces of the rock.

- Normal Pore Pressure: Normal pore pressure is equal to the hydrostatic pressure

- Abnormal Pore Pressure: It is defined as any pore pressure that is greater than the hydrostatic pressure

- Subnormal Pore Pressure: It is defined as any pore pressure that is less than the corresponding pore fluid hydrostatic pressure at a given depth

- Overburden Pressure: Overburden Pressure is defined as the pressure exerted by the total weight of overlying formations above the point of interest,

- Fracture Gradient: It is defined as the pressure at which formation breakdown occurs

Functions of Casing

- Prevent cave-in or washout of the hole

- Prevent contamination between zones

- Exclude water from producing formations

- Confine production to the wellbore

- Provide a means for controlling well pressure

- Provide a path for produced fluids

- Permit installation of artificial lift equipment

Casing Design Principles

Collapse Pressure- This pressure originates from the column of mud used to drill the hole and acts on the outside of the empty casing, Since the hydrostatic pressure of a column of mud increases with depth collapse pressure is highest at the bottom and zero at the top.

Collapse (C):

C = mud density x depth x acceleration due to gravity,

C = ρgh,

C = 0.052 ρ h

Burst: The burst criterion is normally based on the maximum formation pressure resulting from a kick during the drilling of the next hole section.

Therefore, the burst pressure is highest at the top and lowest at the casing shoe where internal pressure is resisted by the external pressure originating from fluids outside the casing.

Burst pressure at the surface (B1) = Pf – G x TD, Calculate the internal pressure (Pi) at the shoe using the maximum formation pressure at the next hole TD, assuming the hole is full of gas:

Pi = Pf – G (TD – CSD)

Pe = 0.465 x CSD,

Burst pressure at shoe (B2) = Pi – Pe

B2 = (Pf – G) x (TD – CSD) – 0.465 x CSD.

Tension: Most of the axial tension arises from the weight of the casing itself, Other tension loadings can arise due to: Bending, Drag, Shock loading, and during pressure testing of the casing.

Calculate the weight of the casing in the air (positive value) using true vertical depth,

Casing air weight = casing weight (lb/ft) * hole depth (TVD),

Calculate buoyancy for (negative value),

BF = Pe (Ae – Ai) for the open-ended casing,

BF = Pe Ae – Pi Ai for closed casing

Very good job am survey engineering work in oilfeild its first time for me to know about rig. So i searched on google i found your. Website. I got alot of information aboht rigs thank you keep it up

Your content is extraordinary

Please save my mail id and Number

If you have any WhatsApp group. Please add me 7013386981

iamsalim.mohammed@gmail.com

Hello am Frank may i get information about specification of Drilling Jars ,Drilling Steam for Water Drilling rig name and Model Ruston Erie L60. Thank you

HI Mr. Anup Kumar,

I was looking for a checklist for drilling rig equipment evaluation and in process got this page.

I requesting if you can guide and provide ”drilling rig equipment evaluation’ template in Xls / word.

My contact details as below