Excavation is a fundamental part of many construction projects, from building foundations to laying infrastructure. However, while excavation is essential, it also comes with significant hazards that can lead to serious accidents if not properly managed. Excavation Hazards are the dangers associated with soil excavation at construction sites. During construction site excavation, both the workers inside trenches and on the surface are at high risk. So protective measures must be considered against the hazards in the excavation. In this article, we will explore different types of excavation hazards during site excavation and the protective measures that should be undertaken to reduce accidents.

Definitions related to Excavation Hazard

- Excavation – a man-made cut, cavity, trench, or depression formed by earth removal.

- Trench – a narrow excavation. The depth is greater than the width but not wider than 4.5 meters.

- Shield – a structure able to withstand a cave-in and protect employees

- Shoring – a structure that supports the sides of an excavation and protects against cave-ins

- Sloping – a technique that employs a specific angle of incline on the sides of the excavation. The angle varies based on an assessment of impacting site factors.

The discussion of this topic covers four main points. At the conclusion of this article, you should be able to:

- State the greatest risk present at an excavation.

- Briefly describe the three main methods for protecting employees from cave-ins.

- Name at least three factors that pose a hazard to employees working in excavations and at least one way to eliminate or reduce each of the hazards.

- Describe the role of a competent person at an excavation site.

Types of Excavation Hazards

Excavation is the removal of soil or rock from a construction site that creates an open space for installing pipes, equipment, etc. using various construction tools, machinery, or explosives. So, excavation creates a hole or cavity that is hazardous. Various types of excavation hazards arise at the construction site. Cave-ins or collapses are the greatest risks. Other hazards include:

- Asphyxiation due to lack of oxygen

- Inhalation of toxic materials

- Fire

- Excavated Soil or Equipment falling on workers.

- Moving machinery near the edge of the excavation can cause a collapse.

- Falling, Slips, Trips

- The accidental severing of underground utility lines/power lines.

- Material handling Hazards.

Excavation is one of the most hazardous construction activities. Most accidents occur in trenches 1.2 to 4.5 meters deep. There is usually no warning before a cave-in.

1. Cave-ins

Cave-ins are perhaps the most dangerous excavation hazard. They occur when the walls of a trench or excavation site collapse, burying workers under tons of soil.

1.1 Reasons of Cave-ins

The main causes of cave-ins include:

- Unstable Soil: Soil types such as sandy or loose soils are more prone to collapse. Clay and silt can also become unstable when wet.

- Improper Shoring: Shoring systems (support structures) that are incorrectly installed or inadequate can fail, leading to cave-ins.

- Water Accumulation: Rain or groundwater infiltration can weaken soil stability, increasing the risk of cave-ins.

- Vibration: Nearby construction activities or heavy traffic can cause soil to shift and destabilize excavation walls.

1.2 Precautions from Excavation Hazards, Cave-ins

Employees should be protected from cave-ins by using an adequately designed protective system. Protective systems must be able to resist all expected loads to the system.

1.3 Protective system from Cave-ins

A method of protecting employees from cave-ins, from material that could fall or roll from an excavation face or into an excavation, or from the collapse of adjacent structures. Protective systems include

- support systems,

- sloping and benching systems,

- shield systems, and

- other systems that provide the necessary protection.

Additionally, the following measures should be undertaken:

- Soil Analysis: Conduct a thorough soil analysis to determine soil type and stability.

- Shoring and Shielding: Use proper shoring (bracing) and shielding systems designed for the specific excavation depth and soil conditions.

- Drainage Systems: Implement effective drainage solutions to manage water accumulation.

- Regular Inspections: Conduct regular inspections of excavation sites to identify and address potential hazards.

1.4 Excavation Safety Plan Requirements

A well-designed protective system means

- Correct design of sloping and benching systems.

- Correct design of support systems, shield systems, and other protective systems.

- Appropriate handling of materials and equipment.

- Attention to correct installation and removal.

Several factors come into play when developing a total protective system. The design of the system itself, how materials and equipment are handled in and around the excavation, and the installation and removal of protective system components.

1.5 Design of Protective Systems against Excavation Hazards and Risks

The employer shall select and construct :

- slopes and configurations of sloping and benching systems

- support systems, shield systems, and other protective systems

- Shield – can be permanent or portable. Also known as trench box or trench

- Shoring – such as a metal hydraulic, mechanical, or timber shoring system that supports the sides

- Sloping – from sides of an excavation that are inclined away from the excavation

1.6 Protect Employees Exposed to Potential Cave-ins

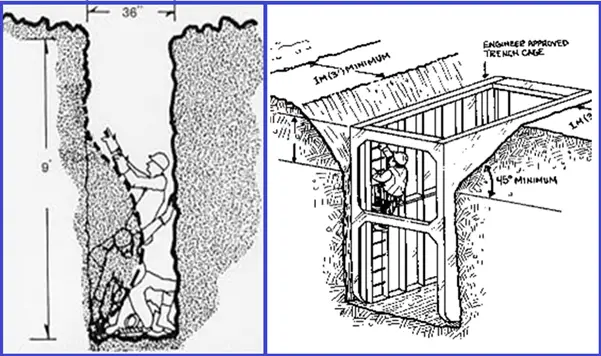

To protect personnel from cave-in excavation hazards (Fig. 1) the following preventive measures can be undertaken

- Maintain at least a 2 m distance from the edge of the cut and use blocks to prevent over-run.

- Slope or bench the sides of the excavation,

- Make proper arrangements to barricade the area being excavated.

- Support the sides of the excavation, or

- Place a shield between the side of the excavation and the work area

1.7 Controlling Factors for Excavation Protective System

Various factors need to be considered while designing a protective system against the hazards and risks of excavation. Those are

- Soil classification

- Depth of cut

- The water content of the soil

- Changes due to weather and climate

- Other operations in the vicinity

- The employer or his designee must select and construct designs of support systems, shield systems, and other protective systems.

- Trenches more than 5 feet require shoring or must have a stabilized slope

- Trenches less than 5 feet – a competent person must inspect to determine that a protection system is not necessary for soils where there is no indication of a potential cave-in

- In hazardous soil conditions, trenches under 5 feet need protection

1.8 Shoring in Construction

Shoring in construction means erecting a temporary structure to support unsafe excavation walls or other unsafe structures till work is finished.

- Provides a framework to work in

- Uses Wales, cross braces, and uprights

- Supports excavation walls

- Must know the soil type

- Must know the depth and width of the excavation

- Must be familiar with the OSHA or other relevant standard Tables

Trench Shield: A trench shield must be built around the work area.

1.9 Hydraulic Trench Support

Using hydraulic jacks the operator can easily drop the system into the hole. Once in place, hydraulic pressure is increased to keep the forms in place. Trench pins are to be installed in case of hydraulic failure

1.10 Materials and Equipment

- Materials and equipment used for protective systems shall be free from damage or defects that might impair their proper function.

- Manufactured materials and equipment used for protective systems shall be used and maintained in a manner that is consistent with the recommendations of the manufacturer, and in a manner that will prevent employee exposure to hazards.

- When material or equipment that is used for protective systems is damaged, a competent person shall examine the material or equipment and evaluate its suitability for continued use. If the competent person cannot assure the material or equipment is able to support the intended loads or is otherwise suitable for safe use, then such material or equipment shall be removed from service and shall be evaluated and approved by a registered professional engineer before being returned to service.

1.11 Protection from Vehicles during excavation

- Install barricades

- Hand/mechanical signals

- Stop logs

- Grade soil away from the excavation

- Fence or barricade trenches left overnight

1.12 Hazardous Conditions

- The weight and vibrations of the crane make this a very hazardous condition.

- They should not be working under this crane.

- In addition to the unprotected trench, a cave-in hazard is increased by machinery which gets too close.

- Even normal vehicular traffic, such as that along an adjacent interstate or road through an industrial part may impact an excavation. The vibrations from continuous or heavy traffic may undermine the soil and cause a cave-in.

1.13 Excavation Spoils

Excavation spoils are the soil, dirt, and rubble that are removed while excavating. The following considerations should be made for preventing hazards from excavation spoils.

- Don’t place spoils within 2 feet of the edge of an excavation

- Measure from the nearest part of the spoil to the excavation edge

- Place spoils so rainwater runs away from the excavation

- Place spoil well away from the excavation

2. Other Excavation Hazards

2.1 Falling Loads

Falling loads involve materials or equipment falling into an excavation site, which can pose severe risks to workers. Causes include:

- Improper Material Storage: Materials stored too close to the edge of an excavation can fall in.

- Equipment Movement: Construction equipment near the excavation site can accidentally drop loads.

- Unsecured Loads: Loads that are not properly secured can shift and fall.

2.1.1 Preventative Measures from Falling Loads:

- Secure Storage: Keep materials and equipment well away from the edge of excavations.

- Use Barriers: Install barriers or guardrails to prevent accidental falls of materials.

- Proper Training: Ensure that workers handling equipment are trained in secure load practices.

2.2 Falling into Excavations

Workers and pedestrians can accidentally fall into excavations if proper safeguards are not in place. This can result in severe injuries or fatalities.

2.2.1 Preventative Measures from Falling into Excavations:

- Guardrails and Covers: Install guardrails and covers around excavation sites to prevent falls.

- Warning Signs: Place clear warning signs around excavation areas.

- Access Control: Restrict access to excavation sites to authorized personnel only.

2.3 Utility Strikes

Excavation work often intersects with existing utilities such as gas, water, or electrical lines. Striking these utilities can lead to dangerous situations such as explosions, floods, or electrocution.

2.3.1 Preventative Measures from Utility Strikes:

- Utility Locating: Use utility locating services to map out existing underground utilities before digging.

- Safe Digging Practices: Employ safe digging practices, such as hand digging near known utility lines.

- Emergency Procedures: Develop and communicate emergency procedures for utility strikes.

2.4 Equipment Hazards

Excavation work involves various types of equipment, including backhoes, excavators, and bulldozers. Hazards associated with equipment include:

- Equipment Overturns: Heavy machinery can overturn if used improperly or if the ground is unstable.

- Moving Parts: Equipment with moving parts can cause injuries if proper safety precautions are not followed.

- Blind Spots: Equipment operators may have limited visibility, increasing the risk of accidents.

2.4.1 Preventative Measures from Equipment Hazards:

- Operator Training: Ensure that all equipment operators are properly trained and certified.

- Maintenance: Regularly maintain and inspect equipment to ensure it is in good working condition.

- Safety Measures: Use spotters to guide equipment operators and maintain clear communication on-site.

2.5 Exposure to Hazardous Atmospheres

Excavations, especially those of significant depth, can sometimes encounter hazardous atmospheres, including toxic gases, low oxygen levels, or high levels of particulates.

2.5.1 Preventative Measures from Exposure to Hazardous Atmosphere:

- Air Monitoring: Use air monitoring equipment to check for hazardous atmospheric conditions.

- Ventilation: Implement proper ventilation systems to ensure a safe working environment.

- Protective Equipment: Provide workers with appropriate personal protective equipment (PPE) such as respirators.

- Test excavations more than 1.2 meters before an employee enter the excavation for:

- Oxygen deficiency

- High combustible gas concentration

- High levels of other hazardous substances

Employees shall not be permitted to work in hazardous and/or toxic atmospheres. Such atmospheres include those with:

- less than 19.5% oxygen,

- a combustible gas concentration greater than 20% of the lower flammable limit, and,

- concentrations of a hazardous substance that exceed those specified in the Threshold Limit Values for airborne contaminants established by the ACGIH.

2.6 Preventing Excavation Hazards from Water

Water is Hazardous. So,

- Employees shall not work in excavations in which there is accumulated water, or in excavations in which water is accumulating unless adequate precautions have been taken to protect employees against the hazards posed by water accumulation. The precautions necessary to protect employees adequately vary with each situation but could include special support or shield systems to protect from cave-ins, water removal to control the level of accumulating water, or the use of a safety harness and lifeline.

- If water is controlled or prevented from accumulating by the use of water removal equipment, the water removal equipment and operations shall be monitored by a competent person to ensure proper operation.

- If excavation work interrupts the natural drainage of surface water (such as streams), diversion ditches, dikes, or other suitable means shall be used to prevent surface water from entering the excavation and to provide adequate drainage of the area adjacent to the excavation.

- Water = Cave-in Hazard

2.7 Means of Egress

- A stairway, ladder, or ramp must be present in excavations that are 1.2 meters or deeper

- Structural ramps that are used solely by employees as a means of access or egress from excavations shall be designed by a competent person. Structural ramps used for access or egress of equipment shall be designed by a competent person qualified in structural design and shall be constructed in accordance with the design.

- Ramps and runways constructed of two or more structural members shall have the structural members connected together to prevent displacement.

- Structural members used for ramps and runways shall be of uniform thickness.

- Cleats or other appropriate means used to connect runway structural members shall be attached to the bottom of the runway or shall be attached in a manner to prevent tripping.

- Structural ramps used in lieu of steps shall be provided with cleats or other surface treatments o the top surface to prevent slipping.

2. 8 Protection from Falls, Falling Loads, and Mobile Equipment

- Install barricades

- Use hand / mechanical signals

- Grade soil away from the excavation

- Fence or barricade trenches left overnight

- Use a flagger when signs, signals, and barricades are not enough protection

To protect employees from these hazards, take the following precautions:

- Keep materials or equipment that might fall or roll into an excavation at least 2 feet from the edge of excavations, or have retaining devices, or both.

- Provide warning systems such as mobile equipment, barricades, hand or mechanical signals, or stop logs, to alert operators of the edge of an excavation. If possible, keep the grade away from the excavation.

- Provide scaling to remove loose rock or soil or install protective barricades and other equivalent protection to protect employees against falling rock, soil, or materials.

- Prohibit employees from working on faces of sloped or benched excavations at levels above other employees unless employees at lower levels are adequately protected from the hazard of falling, rolling, or sliding material or equipment.

- Prohibit employees under loads that are handled by lifting or digging equipment. To avoid being struck by any spillage or falling materials, require employees to stand away from vehicles being loaded or unloaded. If cab vehicles provide adequate protection from falling loads during loading and unloading operations, the operators may remain in them.

Competent Person against Excavation Hazards

Must have had specific training in and be knowledgeable about:

- Soils classification

- The use of protective systems

- The requirements of the standard

- Must be capable of identifying hazards, and authorized to immediately eliminate hazards

Inspections of Excavations

A competent person must make daily inspections (Fig. 2) of excavations, areas around them, and protective systems:

- Before work starts and as needed,

- After rainstorms, high winds, or other occurrences which may increase hazards, and

- When you can reasonably anticipate an employee will be exposed to hazards.

If the competent person finds evidence of a possible cave-in, indications of failure of protective systems, hazardous atmospheres, or other hazardous conditions:

- Exposed employees must be removed from the hazardous area

- Employees may not return until the necessary precautions have been taken

Site Evaluation Planning

Before beginning excavation:

- Evaluate soil conditions

- Construct protective systems

- Test for low oxygen, hazardous fumes, and toxic gases

- Provide safe in and out access

- Underground services

- Determine the safety equipment needed

Summary

- The greatest risk in an excavation is a cave-in.

- Employees can be protected through sloping, shielding, and shoring the excavation.

- A competent person is responsible for inspecting the excavation.

- Other excavation hazards include water accumulation, oxygen deficiency, toxic fumes, falls, and mobile equipment.

Excavation work is an integral part of construction but comes with inherent hazards that require careful management. By understanding the common hazards, implementing effective safety measures, and adhering to regulatory standards, construction professionals can significantly reduce the risks associated with excavation. Continuous education, proper planning, and diligent supervision are key to maintaining a safe excavation environment. Prioritizing safety not only protects workers but also contributes to the overall success of construction projects.

Few more useful resources for you…

What is Engineering Process Safety?

Safety Rules during A Field Visit By A Design Engineer

An article on Crane safety during Construction

HAZOP (Hazard and Operability) Study: A brief introduction

An article on Excavation Hazards at Construction Sites

Hazardous Area- Theory, Classification and Equipment selection: A short presentation

An article on THE HAZARDS OF PRESSURE TESTING

Good write ups by the author. Safety precaoutions by the excavators must be in considerations to avoid death during excavation.

Thanks for the reminder that having barricades should be part and parcel with civil excavation services. I’d like to get my garden excavated soon in order to check the underground utilities there. I’d like to make sure that that aren’t being damaged by the roots of my trees so it’s best to get them inspected.

Very nice for study purpose

Great research surely, thanks. Edwin. God purely bless u. Nembabazi.

Excavation is one of the most hazardous activity in construction activity.

Before taking up this activity, expert should explore all the potential hazards and control measures.

I was faculty for this activity for GETs .