What is HAZOP Analysis?

The full form of HAZOP is a Hazard and Operability Study. This is a comprehensive multi-disciplinary team exercise to critically review (Analyze) the piping design (Layout/ Routing/Placement of branches/inline instrumentation items/equipment, etc.) with respect to Hazardous and Operational considerations and requirements.

A Hazard and Operability (HAZOP) analysis is a structured and systematic examination of a planned or existing process or operation in order to identify and evaluate problems that may pose risks to personnel or equipment or prevent efficient operation. This is a well-documented study and forms part of the quantitative risk assessment.

The HAZOP analysis technique was initially developed to analyze chemical process systems but has later been extended to other types of systems and also to complex operations and to software systems.

A HAZOP analysis is a qualitative technique based on guidewords and is carried out by a multi-disciplinary team (HAZOP team) during a set of meetings. A few of the common HAZOP analysis guidewords are listed below:

- No or not

- Other than

- More

- Early

- Less

- Late

- As well as

- Before

- Part of

- After

- Reverse (of intent)

- Others can be crafted as needed

HAZOP Analysis Mechanism

HAZOP analysis is now a mandatory activity. It is a qualitative, experience-intensive exercise. It is in the form of deviation analysis. After the process design, the steady-state specifications of each stream in the flowsheet are known.

The HAZOP analysis team exhaustively asks itself questions as to what will happen if this specification deviates on the positive or negative side of the expected steady-state value. It debates the possible causes and consequences of each such eventuality. Anything that appears to them as likely to lead to hazardous situations is debated further, and possible means of avoiding the same or raising alarm if it happens so that remedial action can be taken, etc. are recommended. This may lead to the recommendation of additional instrumentation on lines and equipment, Hi-Lo alarms and trips, etc. may be required to be provided.

The idea of HAZOP analysis is to foresee a hazardous situation and take measures and abundant precautions to avoid them and increase process safety.

Hazop analysis is a structured analysis, conducted after the design review, to ensure the design is suitable for all the intended operating conditions and complies with the HSE requirements. This process also ensures that the fundamentals of the design are thoroughly explained, understood, and examined.

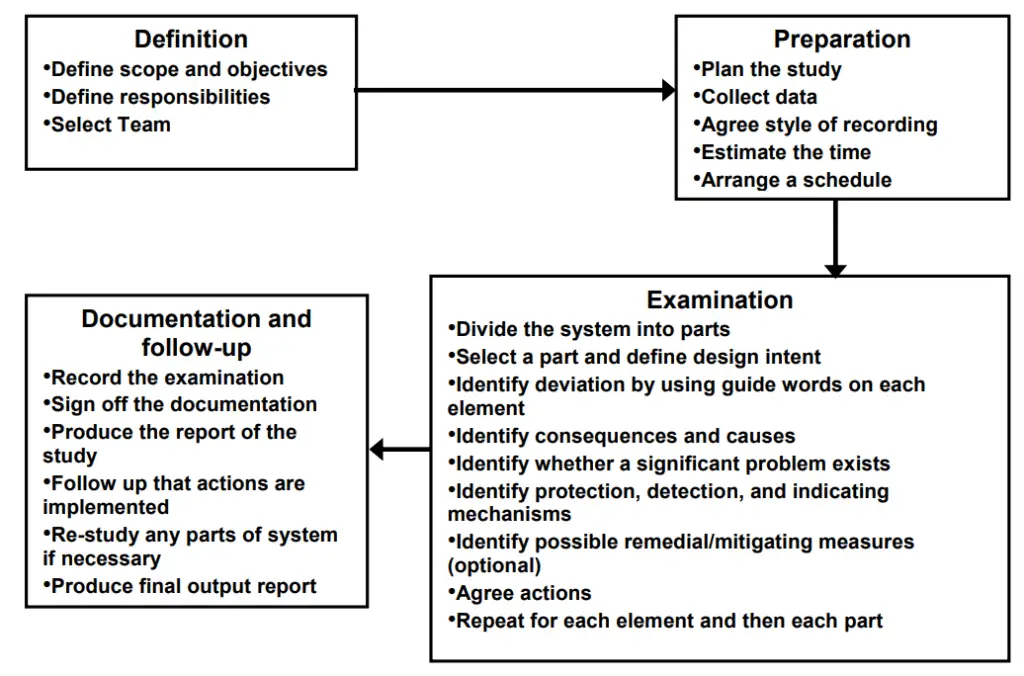

Basically, HAZOP analysis is performed in four phases as listed below:

- Definition Phase

- Preparation Phase

- Examination and

- Documentation and follow-up phase.

Important characteristics of all four HAZOP analysis phases are provided in the image below.

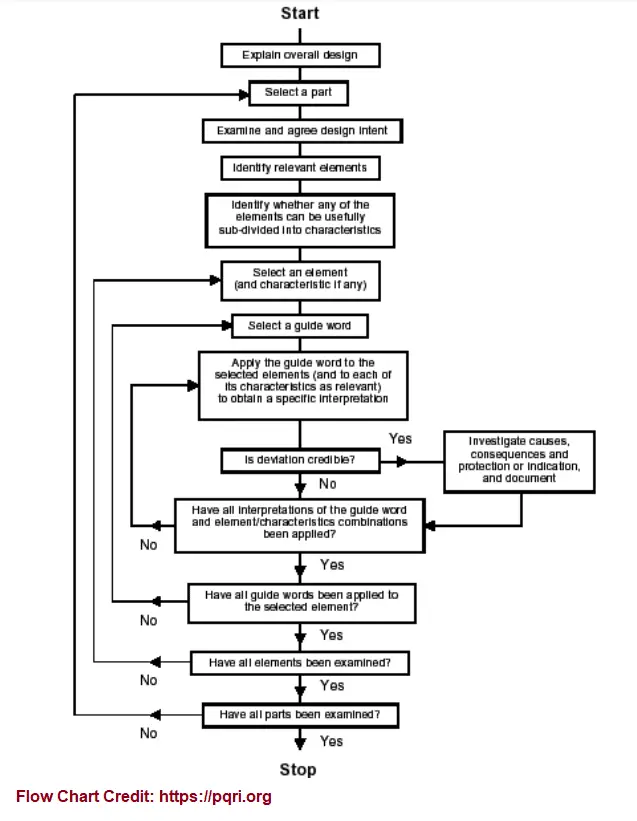

The examination phase is the most important HAZOP analysis phase among the four phases. A typical flowchart of the HAZOP Examination phase is provided below:

Advantages of HAZOP analysis

The benefit of the HAZOP is that early identification and assessment of critical hazards provide essential input to project development decisions. This leads to a safer and more cost-effective design with a minimum cost of change penalty. Other benefits of HAZOP are

- It works as a qualitative risk assessment tool

- During the brainstorming session based on past experiences, all lessons learned safety points are taken care of to prevent re-occurrence.

- HAZOP is a very simple and effective method.

- As HAZOP is a cross-functional team effort; experiences from all disciplines combine into the design for highly safe operation.

- HAZOP is a powerful communication tool for obtaining early buy-in on the approach.

Key Documents required for HAZOP analysis

Important documents required during a HAZOP Study are:

- PFD / PFSs (Process Flow Diagram/ Process Flow Schemes)

- P&ID / PEFSs (Piping & Instrument Diagrams/ Process Engineering Flow Schemes)

- Basis of Design

- Operating, controlling, and safeguarding philosophy

- Plot plans & Hazardous area classification drawings

- Cause & Effect diagrams

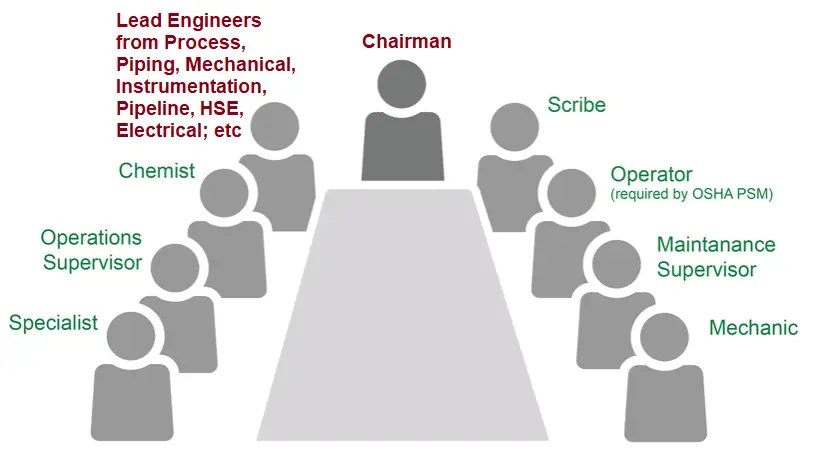

HAZOP Analysis Team Composition

Normally a HAZOP review team consists of

- Chairman (independent)

- Lead engineers from Process, Instrumentation & Control (both from the Design team and Client/ End-user)

- Operations engineer (from Client/ End-user)

- Lead engineers from Mechanical/Piping, Pipeline, HSE, and Electrical as required. (Both from the Design team and Client/ End-user)

The following image shows a typical team composition for HAZOP Analysis.

HAZOP Analysis Timings

The HAZOP analysis study should preferably be carried out as early in the design phase as possible to have an influence on the design. On the other hand; to carry out a HAZOP we need a rather complete design. As a compromise, the HAZOP is usually carried out as a final check when the detailed design has been completed.

A HAZOP study may also be conducted on an existing facility to identify modifications that should be implemented to reduce risk and operability problems.

Typically HAZOP analysis in EPC design companies is performed 3 to 4 weeks after the design review meeting, once the design review points are incorporated in the key documents.

Application of HAZOP Analysis

In recent times, the HAZOP study has gained worldwide acceptance across various industries due to its inherent benefits. The main industries are:

- Chemical,

- Petro-chemical

- Pharmaceutical

- Refinery

- Food

- Oil and gas

- Nuclear

- Fertilizer

- Power plants

Few more useful resources for you…

What is Engineering Process Safety?

Safety Rules during A Field Visit By A Design Engineer

An article on Crane safety during Construction

HAZOP (Hazard and Operability) Study: A brief introduction

An article on Excavation Hazards at Construction Sites

Hazardous Area- Theory, Classification and Equipment selection: A short presentation

An article on THE HAZARDS OF PRESSURE TESTING

Very good blog post. I absolutely appreciate this site.

Keep writing!

Very good describes, all thing of HAZOP study, keep it up.

Thank you so much for your Hazop instroduction!

Very interesting read. Nice job!!

From VietNam, very useful knowledge