The world around us is shaped by magnificent structures that stand tall as testaments to human ingenuity and innovation. From ancient pyramids to modern skyscrapers, each architectural marvel is a result of meticulous planning and expert structural design. Structural design is the backbone of any construction project, ensuring the safety, stability, and functionality of buildings, bridges, and infrastructure. In this article, we’ll delve into the fascinating world of structural design, exploring its principles, key considerations, and the role it plays in shaping the future of our societies.

What is Structural Design?

At its core, structural design involves the art and science of creating safe and stable structures that can withstand various forces. Engineers employ mathematical and scientific principles, combined with creative thinking, to design buildings and infrastructure that can support their intended use. The key factors considered in structural design include:

a. Load Analysis:

Engineers evaluate the loads that the structure must bear, including dead loads (permanent weight like the building itself) and live loads (temporary loads from occupants, furniture, and equipment).

b. Material Selection:

Choosing the right materials, such as concrete, steel, wood, or composite materials, is vital to ensure durability and stability.

c. Forces and Load Distribution:

Structural designers carefully analyze how forces like gravity, wind, earthquakes, and temperature fluctuations will affect the structure and devise mechanisms to distribute these loads effectively.

Objectives of Structural Design

The objectives of structural design are to ensure that a building or infrastructure project meets specific criteria related to safety, stability, functionality, and durability. The primary goals of structural design are as follows:

Safety:

The paramount objective of structural design is to create a safe environment for occupants and users. Engineers must design structures that can withstand various loads, forces, and environmental conditions without compromising on safety. This includes considering factors like load-bearing capacity, structural stability, fire safety, and resistance to natural disasters like earthquakes, hurricanes, and floods.

Stability and Structural Integrity:

The structural design aims to create stable and reliable structures capable of supporting their intended loads and functions over their expected lifespan. Engineers analyze the forces acting on the structure and develop appropriate support systems, connections, and load distribution mechanisms to maintain structural integrity.

Functionality:

The design must ensure that the structure meets its intended purpose effectively. Whether it’s a residential building, office space, bridge, or any other infrastructure, the design must accommodate the functional requirements of the project and provide a safe and comfortable environment for its occupants.

Economy and Efficiency:

Structural design seeks to optimize the use of materials and resources, leading to cost-effective solutions. Engineers aim to strike a balance between structural safety and construction costs, maximizing efficiency without compromising quality.

Sustainability:

With growing concerns about environmental impact, sustainability has become an essential objective in structural design. Designers focus on utilizing eco-friendly materials, minimizing energy consumption, and considering the long-term environmental effects of the structure.

Compliance with Building Codes and Regulations:

Structural design must adhere to local building codes, regulations, and standards set by relevant authorities. Compliance ensures that the structure meets safety and environmental requirements, and it is legally permissible for construction.

Aesthetics and Architectural Integration:

While safety and functionality are critical, structural design also plays a role in shaping the visual appeal of a structure. Engineers work closely with architects to integrate structural elements seamlessly into the overall architectural design.

Adaptability and Future Expansion:

In some cases, structures need to be adaptable to potential future expansions or changes in use. Structural designers take into account potential modifications or additions to ensure the building can accommodate future needs without compromising safety.

Ease of Construction and Maintenance:

The design should consider constructability, ease of assembly, and efficient use of construction materials. Additionally, it should be designed in a way that allows for straightforward maintenance and repair throughout its lifespan.

Innovation and Technological Advancements:

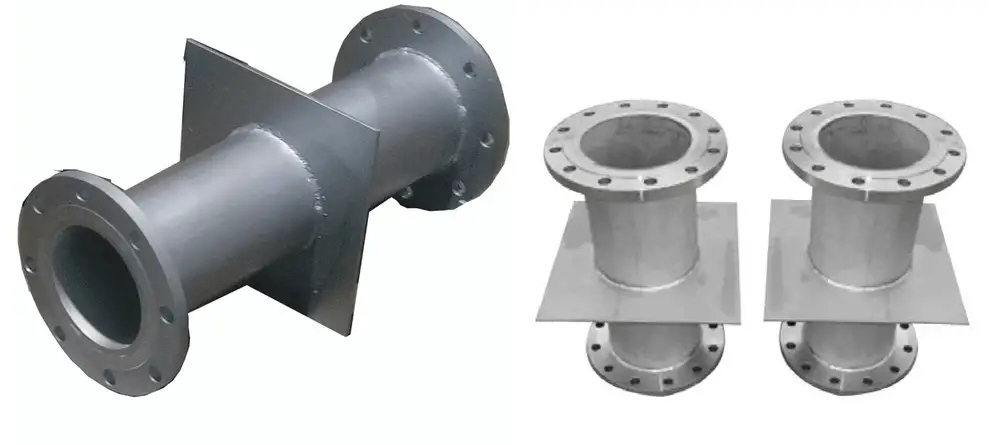

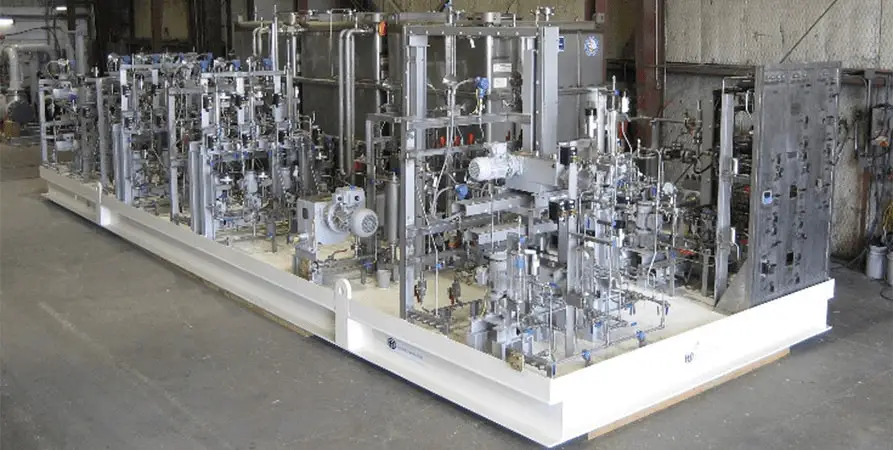

Advancements in technology and construction techniques continuously influence structural design. Designers aim to stay updated with the latest innovations to incorporate them into their projects, resulting in more robust and efficient structures. Fig. 1 below shows a typical complex structural design from a refinery complex.

Building Codes and Safety

Building codes and regulations are critical components of structural design. They are established by governments to ensure that structures meet specific safety standards, adhere to environmental norms, and protect inhabitants during natural disasters. Compliance with these codes is mandatory, and structural engineers must be well-versed in them while developing their designs.

Types of Structures

The structural design extends to various types of buildings and infrastructure, each with its unique challenges. Some common types of structures include:

- Residential Buildings: Houses, apartments, and other living spaces require designs that cater to the comfort and safety of the residents.

- Commercial Buildings: Office buildings, shopping malls, and recreational centers demand designs that accommodate large numbers of people and diverse functionalities.

- Bridges: Bridge design must account for dynamic forces, traffic loads, and environmental conditions to ensure stability and longevity.

- Towers and Skyscrapers: Tall structures necessitate innovative designs to withstand wind and seismic forces while maximizing usable space.

Stages in Structural Design

The process of structural design involves several stages that collectively ensure the creation of a safe, stable, and functional structure. These stages may vary slightly depending on the project’s complexity and the organization’s workflow, but the fundamental steps remain consistent. Here are the typical stages in structural design:

Project Brief and Feasibility Study:

In this initial stage, the project’s requirements and objectives are defined. Engineers work with architects, clients, and stakeholders to understand the project’s purpose, function, budget, and timeline. A feasibility study is conducted to evaluate whether the proposed project is practical and achievable.

Site Investigation and Analysis:

Engineers conduct a thorough site investigation to assess the environmental conditions, soil properties, and geotechnical factors that may impact the design. The analysis of this data helps in determining the appropriate foundation design and any necessary site-specific considerations.

Load and Design Criteria:

The structural design team determines the various loads that the structure will experience, including dead loads (permanent weight), live loads (occupants and temporary loads), environmental loads (wind, earthquakes, temperature), and any other relevant loads specific to the project. Design criteria, such as safety factors and deflection limits, are established based on building codes and standards.

Conceptual Design:

During this stage, the structural engineers develop several conceptual design options based on the project requirements and load analysis. These concepts explore different structural systems and materials to achieve the desired functionality and aesthetics.

Structural Analysis and Simulation:

Once a preferred conceptual design is chosen, engineers perform a detailed structural analysis using computer software to simulate the behavior of the structure under various loads and conditions. The analysis verifies that the design meets safety standards and structural performance criteria.

Design Development:

In this stage, the chosen conceptual design is refined and detailed to address specific architectural and functional requirements. Engineers finalize the selection of materials, dimensions, structural members, connections, and other essential design elements.

Construction Drawings and Specifications:

Detailed construction drawings and specifications are prepared to communicate the design intent to contractors and builders. These documents include plans, elevations, sections, and other technical details required for construction.

Permits and Approvals:

The structural design, along with other architectural and engineering plans, is submitted for regulatory approvals and building permits. The design must comply with local building codes and regulations to obtain the necessary approvals for construction.

Construction and Quality Control:

During the construction phase, engineers may oversee or assist with quality control to ensure that the actual construction aligns with the approved design. They may conduct inspections, monitor progress, and address any unforeseen challenges that arise during construction.

Structural Integrity and Safety Testing:

After construction, structural engineers may conduct testing and assessments to ensure the structure’s integrity and safety. This may include load testing, non-destructive testing, and other evaluations to verify the structure’s performance.

Occupancy and Maintenance:

Once the structure is completed and approved, it is ready for occupancy and use. Regular maintenance and periodic inspections are essential to ensure the structure’s continued safety and longevity throughout its design life.

Structural Design Engineering

Structural design engineering is a specialized branch of civil engineering that focuses on the analysis, planning, and design of structures to ensure their stability, safety, and functionality. It involves the application of scientific and mathematical principles to create buildings, bridges, and other infrastructure that can withstand various forces and loads while maintaining structural integrity.

Key aspects of structural design engineering include:

- Analysis of Loads and Forces

- Material Selection

- Structural Systems and Design Principles

- Building Codes and Regulations

- Computer-Aided Design (CAD) and Simulation

- Collaboration with Architects and Construction Teams

- Sustainability and Innovation

Steel Structural Design

Steel structural design refers to the process of planning, analyzing, and creating structural systems using steel as the primary construction material. Steel is a versatile and widely used material in the construction industry due to its high strength, ductility, durability, and ability to resist various loads and forces. Steel structural design encompasses the engineering principles and practices required to design buildings, bridges, industrial facilities, and other structures made predominantly or entirely from steel.

Key aspects of steel structural design include:

Load Analysis:

Steel structural designers analyze the loads that the structure will bear, including dead loads (self-weight of the structure), live loads (occupants, furniture, equipment), environmental loads (wind, snow, earthquakes), and any other relevant loads.

Material Properties:

Understanding the mechanical properties of steel, such as yield strength, tensile strength, elasticity, and ductility, is crucial for determining the structural members’ dimensions and configurations.

Structural Systems:

Steel structural designers develop various structural systems, such as trusses, beams, columns, and frames, to efficiently distribute loads and resist forces. These systems work together to ensure stability and safety.

Connections:

Properly designed connections are vital in steel structural design to transfer loads between members and maintain the integrity of the structure. Bolted, welded, and other types of connections are used based on specific design requirements.

Building Codes and Standards:

Compliance with building codes and standards is essential to ensure that steel structures meet safety and performance requirements. Codes set guidelines for the design, fabrication, and construction of steel structures.

Computer-Aided Design (CAD) and Structural Analysis:

CAD software is widely used in steel structural design to create detailed 3D models and construction drawings. Structural analysis software helps engineers simulate the behavior of steel structures under various loads and conditions.

Design Optimization:

Steel structural designers aim to optimize the design by finding the most efficient use of steel materials while meeting safety and functionality criteria. This involves balancing the steel’s cost with the desired performance.

Construction Methods:

Steel structural design also considers construction methods and techniques, as steel structures are often prefabricated and assembled on-site.

Steel structural design is applied to a wide range of projects, including commercial buildings, industrial facilities, warehouses, bridges, and high-rise structures. The combination of steel’s properties and the expertise of structural engineers allows for the creation of robust, flexible, and aesthetically appealing structures that stand the test of time. The durability and strength of steel make it a preferred choice for critical infrastructure, where safety and performance are paramount.

Structural Design Software Packages

There are several widely used structural design software packages that are popular among engineers and architects for designing and analyzing various types of structures. These software tools offer advanced features, simulation capabilities, and 3D modeling to ensure efficient and accurate structural designs. Some of the most widely used structural design software are:

ETABS (Extended Three-Dimensional Analysis of Building Systems):

ETABS is a popular software for the analysis and design of buildings. It offers comprehensive capabilities for the static and dynamic analysis of structures, including high-rise buildings, industrial structures, and bridges. ETABS is known for its robust modeling tools and efficient design features.

SAP2000:

SAP2000 is another versatile structural analysis and design software developed by the same company as ETABS. It is commonly used for linear and nonlinear analysis of structural systems, and it supports a wide range of materials, including steel, concrete, and composite materials.

STAAD.Pro:

STAAD.Pro is a widely used structural analysis and design software that supports a variety of structural elements and materials. It can handle linear and nonlinear analysis, and it is commonly used for the design of buildings, bridges, and other structures.

Robot Structural Analysis Professional:

This software, developed by Autodesk, is used for advanced structural analysis and simulation. It is commonly used in the design of buildings and industrial structures and offers seamless integration with other Autodesk products like Revit and AutoCAD.

SAFE:

SAFE is specifically designed for the analysis and design of foundations, including flat slabs, mat foundations, and rafts. It is widely used for designing the foundations of buildings and industrial structures.

RAM Structural System:

RAM Structural System, developed by Bentley Systems, is a comprehensive software package that offers integrated tools for the analysis, design, and drafting of building structures. It is commonly used for designing buildings of all types and sizes.

Tekla Structures:

Tekla Structures is primarily used for building information modeling (BIM) and the design of steel and concrete structures. It offers advanced modeling capabilities and interoperability with other design software.

MIDAS Civil and MIDAS Gen:

The MIDAS suite includes MIDAS Civil for civil engineering applications like bridges and highways, and MIDAS Gen for general structural analysis and design. These tools are known for their versatility and ease of use.

These software tools help engineers and designers perform complex structural analyses, optimize designs, and ensure that structures meet safety and performance requirements. Each software has its unique features and capabilities, and the choice of software depends on the specific project requirements and the preferences of the design team.

Advancements in Structural Design Engineering:

The field of structural engineering continues to evolve, driven by technological advancements and sustainability concerns. Some notable developments include:

- Computer-Aided Design (CAD): CAD software allows engineers to create detailed 3D models of structures, aiding in precise analysis and visualization.

- Building Information Modeling (BIM): BIM facilitates collaboration among architects, engineers, and contractors, leading to better-coordinated projects and reduced errors.

- Green Building Design: Sustainability is a growing focus in structural design, leading to the implementation of eco-friendly materials and energy-efficient features.

- Structural Health Monitoring (SHM): SHM employs sensors and data analysis to assess the health of structures, enabling proactive maintenance and prolonging their lifespan.

Conclusion:

Structural design is an intricate blend of art and science, shaping the world we inhabit. As populations grow, and cities expand, the demand for innovative and sustainable structural solutions will continue to rise. By incorporating cutting-edge technology, adhering to stringent safety standards, and embracing environmentally friendly practices, structural engineers will play a crucial role in building a better, safer, and more sustainable future for generations to come. So, the next time you gaze upon a soaring skyscraper or cross a gracefully designed bridge, remember the extraordinary effort that went into its structural design, silently supporting the world around us.