A Pipe Shaver is a specialized tool used for preparing pipes for joining or fitting installation. They are most widely used for preparing FRP, GRP, PVC, and other plastic pipes. The main purpose of the Pipe Shaver tool is to remove a precise amount of material from the outer surface of a pipe to create a beveled edge or to ensure a smooth and clean surface for proper pipe connection. Pipe shaver machines help achieve a proper fit and alignment between pipes, ensuring efficient flow and minimizing potential leaks.

Pipe Shavers are typically handheld devices that utilize a rotating cutting mechanism to shave pipe or create a taper. They may incorporate cutting blades or abrasive wheels designed specifically for cutting fiberglass or other plastic pipes. These tools are often adjustable to accommodate different pipe sizes and may offer various bevel angles to match specific project requirements.

FRP pipe shavers are available to handle a wide range of pipes, ranging from 2 inches up to 48 inches. They are portable, fast, efficient, and reliable devices.

Applications of Pipe Shaver Tools

Pipe shaver tools have various applications in different industries and sectors. Here are a few common applications:

Pipe Joining and Welding:

Pipe shavers play a crucial role in pipe joining and welding processes. They are utilized to prepare the pipe ends by creating beveled edges or chamfers. These beveled edges allow for better alignment and penetration during welding, resulting in stronger and more secure joints.

Industrial Piping Systems:

In industrial settings, where various types of pipes are used for transporting fluids or gases, pipe shavers are employed to prepare the pipe ends before installation. This ensures that the pipes fit together seamlessly and securely, minimizing the risk of leaks or inefficiencies in the system.

Fiberglass and Composite Piping:

Fiberglass pipe shavers, as mentioned earlier, are specifically designed for preparing fiberglass pipes. They remove material from the outer surface of the pipe, creating beveled edges or ensuring a smooth surface for proper fitting and joining of fiberglass pipes.

Plumbing and Construction:

Pipe shavers are frequently used in plumbing and construction projects. They are employed to remove burrs, rough edges, or excess material from the cut ends of pipes to ensure smooth connections and proper fitment. This helps prevent leaks and ensures efficient flow through the pipes.

Pipeline Maintenance and Repair:

Pipe shavers are useful in pipeline maintenance and repair work. They can remove damaged or corroded sections of a pipe, preparing it for replacement or repair. By shaving the pipe ends, a clean surface is created for the connection of new pipe sections or fittings.

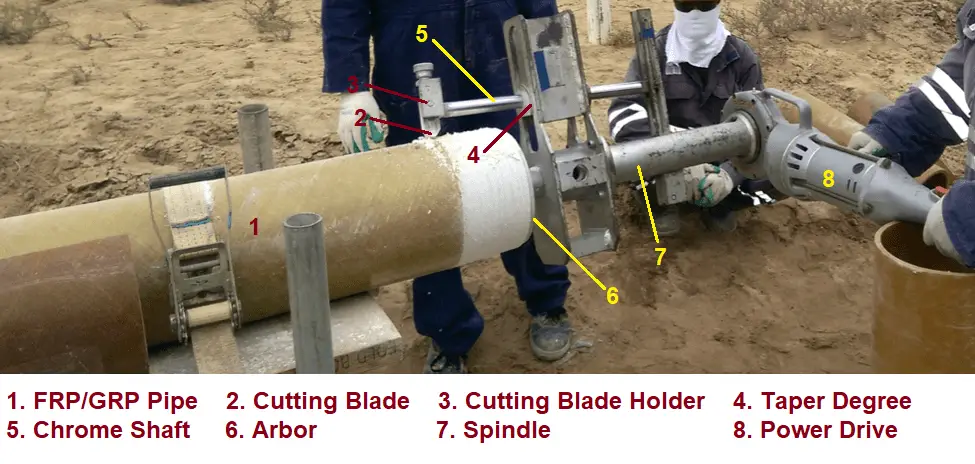

Components of a FRP Pipe Shaver Tool

The specific components of a Fiberglass Reinforced Plastic (FRP) pipe shaver tool can vary depending on the design and manufacturer. However, here are some common components typically found in FRP pipe shavers:

- Cutting Head: The cutting head is the primary component responsible for removing material from the surface of the FRP pipe. It may consist of cutting blades, abrasive wheels, or other cutting mechanisms specifically designed for FRP materials.

- Drive Mechanism: The drive mechanism powers the cutting head and provides the necessary rotation or movement required for material removal. It can be manual, electric, or pneumatic, depending on the type of pipe shaver.

- Adjustable Settings: Many FRP pipe shavers feature adjustable settings to accommodate different pipe sizes and bevel angles. These settings allow users to customize the tool to meet specific requirements.

- Clamping or Holding Mechanism: To ensure stability and accuracy during the shaving process, some pipe shavers may include a clamping or holding mechanism. This component securely holds the pipe in place, preventing movement and ensuring precise shaving.

- Handle or Grip: The handle or grip provides a comfortable and secure hold for the operator. It allows for easy maneuverability and control during the shaving process.

- Depth Adjustment Mechanism: Some pipe shavers have a depth adjustment mechanism that controls the amount of material removed from the pipe’s surface. This mechanism allows for precise control of the cutting depth.

- Safety Features: Depending on the design, FRP pipe shavers may incorporate safety features such as blade guards, safety interlocks, or ergonomic handles to enhance operator safety during operation.

- Power Source: If the pipe shaver is a powered tool, it may include components such as an electric motor, battery pack, or air compressor (in the case of pneumatic tools) as part of the power source. Fig. 1 below shows some of the important components of a pipe shaver machine.

Working of Fiberglass Pipe Shavers

The working principle of Fiberglass Pipe Shavers can vary depending on the specific design and model of the tool. However, the general working principle involves the following steps:

- Secure the Pipe: The fiberglass pipe is securely held or clamped in place to prevent movement during the shaving process. This ensures stability and accuracy during the operation.

- Adjust the Tool: The tool is adjusted to the desired bevel angle or cutting depth, depending on the requirements of the project or specific pipe specifications. Some pipe shavers have adjustable settings to accommodate different pipe sizes and bevel angles.

- Activate the Cutting Mechanism: Once the tool is set up, the cutting mechanism is activated. This may involve turning on a motor that drives the cutting blades or abrasive wheels or engaging a manual cutting action.

- Remove Material: As the cutting mechanism rotates or moves along the surface of the pipe, it removes a precise amount of material from the outer surface. This material removal process creates a beveled edge or a smooth surface, depending on the tool’s design and settings.

- Control and Monitor the Shaving: During the shaving process, the operator controls the tool’s movement, ensuring even and consistent material removal. The operator may need to apply appropriate pressure to achieve the desired shaving result while avoiding excessive cutting or damage to the pipe.

- Inspect the Shaved Surface: Once the shaving process is complete, the operator inspects the shaved surface to ensure it meets the required specifications. This may involve checking for smoothness, bevel angle, or any irregularities that could affect the proper fitting or joining of the pipe.

Note that the specific details of the working principle may vary among different models and manufacturers of Fiberglass Pipe Shavers. Therefore, it’s advisable to consult the manufacturer’s instructions and guidelines for the particular tool being used to ensure proper and safe operation. In short, the following steps must be followed:

- Set diameter and angle

- Fit the Arbor

- Set the taper-cutting angle

- Insert the shaver into the pipe

- Adjust the cutting tool, and then

- Start the shaving process

- Retract the cutting tool and release the central bolt to finish off

Specification of Fiberglass Pipe Shavers

Specifying a Fiberglass Reinforced Plastic (FRP) pipe shaver involves providing detailed requirements and specifications to ensure that the tool meets your specific needs. Here are some key factors to consider when specifying an FRP pipe shaver:

- Pipe Size and Material: Specify the range of pipe sizes (diameter) that the shaver should accommodate. Additionally, mention the type of material the FRP pipes are made of, as different shavers may be designed for specific materials.

- Bevel Angle: Determine the desired bevel angle for the pipe ends. This can vary depending on the project requirements or industry standards. Clearly state the required bevel angle or any specific beveling requirements.

- Cutting Depth: Specify the desired cutting depth or material removal amount. This will ensure that the shaver removes the necessary material for proper fitting or joining of the pipes.

- Power Source: Specify whether you require a manual or powered FRP pipe shaver. Manual shavers are operated by hand, while powered shavers may have electric or pneumatic motors for automated cutting.

- Adjustable Features: If you have specific needs for adjustability, such as variable bevel angles or cutting depth settings, clearly state those requirements. Some shavers may offer adjustable features to accommodate different pipe sizes and beveling needs.

- Safety Features: Consider any specific safety features you require, such as blade guards, ergonomic handles, or safety interlocks. Safety should always be a priority when working with pipe shavers.

- Brand or Manufacturer: If you have a preference for a particular brand or manufacturer, specify it in your requirements. This can help narrow down the options and ensure that you receive products from reputable sources.

- Quantity and Delivery Time: Specify the number of pipe shavers needed and any specific delivery time requirements if applicable.

When specifying an FRP pipe shaver, it’s crucial to provide clear and detailed requirements to the supplier or manufacturer. This will help them understand your needs accurately and provide you with the most suitable options. Additionally, consulting with experts or suppliers in the FRP pipe industry can provide valuable guidance on the specific requirements and available options for FRP pipe shavers.

Safety Considerations

When using a Fiberglass Pipe Shaver, it’s important to follow safety precautions and manufacturer instructions to ensure proper usage and avoid any potential risks. To protect against serious injury or loss of life, comply with the safety measures:

- Safety shoes must be worn

- Working gloves to protect against sharp GRP Materials

- Buttoned-up protective clothing must be worn

- Long hair must be tied

- A dust mask should be used

Notable Manufacturers of Fiberglass Pipe Shavers

When it comes to manufacturers specializing in Fiberglass pipe equipment and tools, the following companies are well-regarded:

- Future Pipe Industries

- Ameron

- NOV

- OTA

- Ershigs