Being a piping engineer you must be familiar with the term “Piping Shoe”. Pipe shoe supports are highly popular for insulated lines. As insulation material is usually not capable to withstand high piping loads, piping shoes are used to transfer the piping loads to secondary civil structures without damaging the insulation.

What is a Piping Shoe?

A pipe shoe is a special type of pipe support structure made of structural members or plates with a flat base. Pipe shoes find major applications for supporting the following pipes:

- Insulated lines.

- Sloping pipes.

- Larger Pipes with smaller thicknesses (Usually pipes> 20-inch size with less than Sch 20 thickness).

Functions of Pipe Shoes

Pipe shoes act as an intermediate member between the pipe and the secondary steel structure and serve the following purposes:

- They stop pipes/ insulation from rubbing against structures thus preventing damage to insulation material.

- By separating the pipe and structure materials separate, they help in preventing galvanic corrosion in case of dissimilar material.

- Pipe shoes help to increase the structural life by not transferring the high pipe temperature to the structure.

- Pipe shoes help in preventing pipe damage for thin-walled pipes in support locations by transferring the loads to structures.

Types of Pipe Shoes

Pipe shoe supports are categorized based on various parameters as provided below:

Depending on the material of construction, pipe shoes are classified into two types: Metallic pipe shoes, and composite pipe shoes.

Metallic Pipe Shoes

As the name suggests, this type of shoe is made from metals. This is the most common type of piping shoe support used in the process and power piping industries. Metallic piping shoes are the oldest type of piping shoes that serving the piping industry for decades. Traditionally, metallic pipe shoes are manufactured from I-beams, channels, or structural plates. Metallic pipe shoes are simple and low-cost piping support solutions for high-temperature piping systems.

Composite Pipe Shoes

Composite pipe shoes offer the best corrosion-resistant alternative to metallic pipe shoes. They are usually UV resistant, strong, and durable. They are a relatively new addition to pipe shoe groups.

Depending on the attachment of pipe shoes to the parent pipe, they are classified into two groups: welded shoes and clamped shoes.

Welded Pipe Shoes

When pipe shoes are directly welded to the pipe, they are known as welded pipe shoes. Welded pipe shoes are normally used for carbon steel pipes for which welding is easy and cheaper. Welded pipe shoes have very high load-carrying capabilities and are suitable for axial and lateral loads.

Clamped pipe Shoes

For certain material, direct welding in pipes are not permitted or welding is costly and difficult. In such a scenario, clamped pipe shoes are used and the pipe shoe is welded on the clamps. For galvanized pipes, stainless steel pipes, DSS pipes, etc clamped pipe shoes are used. Parent pipe-compatible clamp material is chosen so that no galvanic corrosion occurs and then the shoe material is welded on the outside surfaces of the clamps. Clamped piping shoe supports, in general, carry lower loads as compared to welded counterparts. Clamps pipe shoes are not advisable to use as axial stops or line stops.

Depending on the construction, pipe shoes are of two types: T-type shoes and Saddle-type shoes.

T-type Piping Shoes:

They are usually used for pipe shoes having lower loads. Usually, pipes with a size of less than 26 inches use T-type pipe shoes.

Saddle-type Pipe Shoes:

Saddle supports are used for pipes with sizes exceeding 24 inches. They are suitable for carrying high loads.

Deciding Pipe Shoe Lengths

It is a better engineering practice to standardize pipe shoe designs. In most plants, a shoe length of 300 mm is normally used for pipes up to 24-inch size, and a length of 500 mm is used for pipes with diameters exceeding 24 inches. However, depending on the thermal movement at the support location the shoe length needs to be adjusted.

For example, a 300 mm long pipe shoe will support the pipe over the structural member up to a 150 mm longitudinal pipe movement. If the pipe movement is more than 150 mm, then the length of the pipe shoe should be increased accordingly so that the pipe support does not fall off the structural member.

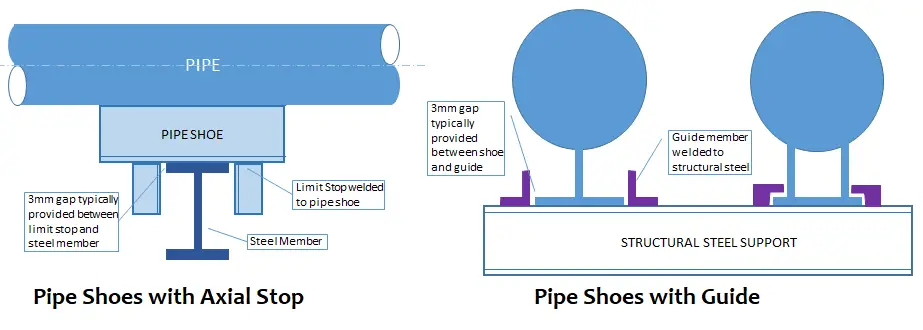

Also, the shoe supports with line stop members usually require more lengths than the standard pipe shoe lengths. So, based on the dimensions of the secondary structural member and line stop member the pipe shoe length needs to be increased.

Factors affecting Pipe Shoe Design

The main parameters that affect the design of pipe shoes are

- Expected Support loads: Members need to be designed based on these loads.

- Pipe Insulation thickness: Pipe shoe height is decided based on the pipe insulation thickness. Normal practice is Piping Shoe Height=Pipe Insulation thickness (mm)+25 mm.

- Thermal Displacement at the support location to decide shoe length.

- Support type in the location: For example line stop supports will require more lengths.

- Shoe material: To be compatible with pipe material.

There are two other terms that are often associated with pipe shoes; Hot Shoe and Cold Shoe.

Hot Shoes: Hot pipe shoes usually refer to pipe supports for high-temperature piping systems.

Cold Shoes: A cold shoe normally refers to a support component that incorporates an insulating material that attaches directly to the pipe. This pipe shoe with insulation functions as a load-bearing component for transferring the pipe load to the structure.

Click here to learn more about Piping Supports

Online Video Courses on Piping Support

To learn more about piping support design and engineering you can opt for the following video course.

I really enjoy reading your blog post, it has really challenged me to make good Engineering decisions when doing my designs. You should write a book sir☺️

Nice explanation

It is a nice post. It is very helpful for me. Thanks for sharing such a great information.