Piping Material Take Off (MTO) is a crucial process of any piping project. It plays an important role in estimating costs, planning resources, and ensuring the smooth execution of the project. Accurate MTOs are the foundation of successful piping projects. Piping Specifications, Fittings, Valves, Special Items, etc are the main components of piping MTO. The main purposes of piping material take-off are:

- Cost Estimation: Piping MTOs enable accurate cost estimation, helping project managers budget effectively and prevent cost overruns.

- Resource Planning: With a clear understanding of required materials, project teams can plan resources efficiently, avoiding delays due to material shortages.

- Procurement Guidance: MTOs guide the procurement process, ensuring that the right materials are sourced in the correct quantities and specifications.

What is Piping MTO or Material Take-Off?

The piping MTO or material take-off is a list of all the piping items required to be purchased to fabricate and construct the design to complete the demand of the project. This list includes all piping items like a pipe, piping fittings, valves, flanges, blind flange, spacer & blank, gasket, fasteners, and the special parts like a strainer, steam trap, flame arrester, rupture disc, expansion bellow, sight glass, hoses, sample cooler, etc.

It’s an essential part of the project estimation process. The material take-off sheet contains a list of all the materials required to complete the project. This list does not include any assets, such as equipment, machinery, and tools. These assets will also be required to complete the job of the project. MTO is prepared line-wise.

Note: Material take-off is different from the Bill Of Material (BOM) and Bill Of Quantity (BOQ).

Information in a Material Take-off Sheet

Material take-off seems to be straightforward but is quite complex in practice. As material take-off helps in the construction cost estimation process, it is necessary to understand what information should be added to the MTO sheet.

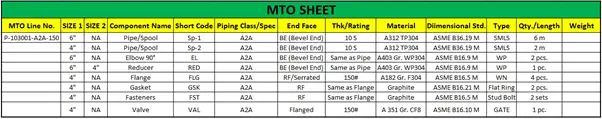

List of the Information available in the Material Take-Off sheet is as follows:

- Line number.

- Name of the piping items.

- Main size.

- Reducing size.

- Shortcode of the items.

- Piping class/specification.

- End/Face type.

- Thickness/Rating

- Material type.

- Dimensional Standard.

- Item type.

- Quantity/Length

- Weight

- Remark (for writing important notes related to piping items).

Note: The above list may vary from company to company.

The sequence of the piping items within the MTO sheet

- Pipe/Spool

- Fittings/component

- Flange

- Gasket

- Fasteners

- Spacer & Blanks

- Valve

- Specialty items

Note: It can be arranged at the convenience of the users.

What is the Bill of Material (BOM)?

In the world of piping, the Bill Of Materials (BOM) often appears on a piping isometric drawing. The BOM contains the list of all the components required to fabricate and construct the line. Piping Isometric provides the list of BOM for a particular line. The piping bill of material is not used for purchasing. It is used to provide the required material from the warehouse to the fabricator for the construction of the piping system as per the isometric drawing. BOM is a document used at the site during the construction phase.

What is the Bill of Quantity (BOQ)?

The Bill Of Quantity (BOQ) is a tendering document. It covers the scope of materials for the entire piping components of the project. However, it is not the final list as it may change further during the MTO preparation at different stages.

BOQ is produced at the starting stage of the project, before construction drawings. Thus, it will not reflect the exact quantity of materials required for the project. But this document finds its use for tendering or bidding.

Stages for Piping Material Take-Off

There are three stages or sessions of material take-off in a process piping project.

- Preliminary,

- Secondary, and

- Final.

There may be more stages depending on the project’s complexity. Sometimes, they are known as zero-level MTO, 30%, 50%, 70%, 90%, final MTO, etc.

Preliminary MTO

The preliminary MTO is prepared at a very early stage in the design process. At this stage, there is usually limited availability of the information. A preliminary MTO is prepared once the P&IDs and Plot plan are approved by the client or have been issued for approval. This is done long before there is any detailed design work started on the 3D modeling software. The preliminary piping material take-off is generated only when the Plot Plan is issued to the client for approval or it is “Approved”. The preliminary piping mto must be done by an experienced piping engineer/designer.

Use of the Preliminary MTO

There are two main reasons for preparing the preliminary MTO:

- Cost estimation

- Bidding of the material/ Request for quotation (RFQ)

Documents required for Preliminary MTO are

- P&ID

- PMS (Piping Material Specification)

Steps for Preliminary MTO Preparation

- Identify the numbers of lines, line classes/specs, and the line size from the P&ID.

- On the MTO sheet, enter the line number, line class, and line size.

- Identify the potential line routing of each line shown on the P&ID and route the line on the plot plan (we can also refer to a similar old project for reference.

- From the line routed on the plot plan, identify the approximate pipe length and estimate the numbers of fittings like elbows, tees, reducers, flanges, etc, and group them size-wise. (The length of the pipe and number of Elbows are not fixed at this stage of MTO).

- Identify the numbers of the valve from the P&ID directly.

- Estimate the High-point vent and low-point drain as per your guess and experiences.

- Enter the detail of the piping components in the MTO sheet following the sequence of the component, you can refer to Fig. 1.

- Now, go to the next line and repeat the same procedure.

- Highlight each line on the P&ID as you complete the above process, that will help in identifying the undone lines.

- Cross-check after completion.

Secondary MTO

When there is significant progress on the piping design, The secondary MTO is prepared. It may include the piping design done on 3D modeling software or 2D software. It must be done early enough to ensure that the procurement of the piping materials could fit the project schedule. This is prepared with the help of the material control group.

Secondary MTO is prepared with the help of PDMS/PMS/E3D by extracting the isometric from the ISO-draft module. This software gives the actual length of the pipes and the number of elbows used in the piping system. It is very difficult to find such information in the preliminary MTO.

Use of the Secondary MTO

There are mainly two reasons for preparing the secondary MTO

- To update the quantities, so that purchase orders for piping items can be issued.

- To update the project cost estimate.

Final MTO

The final piping MTO will identify the actual final material quantity. All items missed in the last MTO or modified due to design modification will be captured. It clears the final material cost required for the project.

The final MTO is prepared when the last isometric has been drawn, checked, approved, and issued. It proceeds in the same manner as the secondary MTO.

Use of the Final MTO

Final MTO is used for updating the last purchase order to fulfill the final need of material so as not to exceed spare material.

Note: MTO stages are not limited to these three only, if there is any modification occurs in the design at any stage of the project, then it is required to update the latest prepared MTO.

Difference Between BOM and MTO

BOM lists all the components for the construction and fabrication of an item. Piping BOM is used as a reference for the warehouse to give the material to the fabricator.

Whereas, MTO lists all items for purchase or procurement. It is a reference for material cost calculation.

Difference between BOM and BOQ

BOM provides a material list for component fabrication and is used at the site during construction.

Whereas, BOQ is a tendering document prepared at an early stage of the project. BOQ provides a basic scope of work based on drawings and specifications.

Few more related Resources for you.

Piping Materials Take-off & Processing: An Overview

Piping Design Basics- Isometric Drawings

Role of a Piping Material Engineer

Good information dear, So such type of information regarding to Project please share

Hi,

You can refer the below link

12 Phases of a Project Implementation (Oil & Gas)

Hi ,

Good information sir.

Can i know where you completed post gradute dimploma in piping engineering.

Kind regards,

Ajit thorat.

Suvidya Institute of Technology, Mumbai

It clarifies many things about the topic.

Hi, thank you for a valuable information. I am technology planner in oil and gas industry. This year I have requirement to implement Engineering Material solution. Any recommendations or experience with similar type of solution.

I have a solution for you. You can now get MTO from AutoCAD P&IDs using the software SSPIPE.

Contact me on my email sanpo@sspipe.net for more details.

Dear Rehan Ahmad Khan

Salam

Thank you so much indeed for the awesome description of MTO, BOM, and BOQ.

I learned a lot from your posts.

All the best

Adel Chaichian

Wassalam Mr. Adel,

I am glad you like it.

Thank you!

Great information Rehan. Keep sharing such valuable posts.

Appreciate your willingness to share these technical details for the benefit of others.

A well written article on MTO BOQ BOM. Thanks