A Material Take Off (MTO) is a process to study a drawing and find out all the materials required to construct the drawing in physical form. In each individual drawing, specific items are listed along with approximate quantities. Those materials are then tabulated in excel or in other company-specific standard forms as per size and quantity involved to make a comprehensive material listing which is sent to the procurement department for purchasing or to the construction team for fabrication. Material Take Off or MTO is a very important step in materials management for procurement and construction.

Depending on the project size and complexity, the materials list or material take-off can be long or short. Without proper management of these materials, unnecessary delay and expense in project execution can happen.

Major Steps in Piping Material Management

The major steps involved in Piping Material Management are:

- Preparation of Piping Material Class

- Preparation of purchase specifications/datasheet for piping specials

- Preparation of Material take-off

- Preparation of Material Requisition

- Receipt of quotations from prospective bidders

- Technical Bid Evaluation

- Vendor document review/approval (post-award)

Material Take Off (MTO) of piping items or piping material take-off is a detailed listing of piping components required for a given project. It includes:

- Commodity Code,

- Size,

- Quantity and

- Purchase description for all the items.

Purpose of Material Take Off

The Material Take Off or MTO is used for the purpose of

- Making Proposal,

- Material Estimation &

- Preparation of Purchase Requisitions.

- Material Take Off helps in a rough estimation of the project cost

Material Take-Off Process

Normally there are three stages of Material Take Off Preparation which are explained in the following article: Introduction to Piping MTO, BOM, BOQ & MTO Stages

Initial MTO (also called First MTO) is generated manually at the beginning of the project. Very often, the 3-D model is not available or complete at that stage. Hence, Initial Material Take Off is generated on the basis of P&ID and Project Specifications.

This is required as the complete modeling takes time and we need the MTO at the earliest to initiate procurement activities.

As the 3D modeling progresses, detailed MTO is generated electronically by the 3D modeling software (PDS/PDMS, etc). The Piping Material Specification is generated in electronic format and is linked to the 3-D modeling software for the purpose.

Accuracy and correctness are of prime importance and digital material take-off provides more accurate estimation in less time with respect to manual MTO estimation.

Following input, documents are required for working out the initial (First) MTO.

- Piping & Instrumentation Diagram (P&ID)

- Line List

- Standard/Project PMS.

- Project specification & standard drawings.

- Equipment Drawings/Data Sheet.

- Instrument Hook-up Sketches.

Manual Material Take-Off Preparation

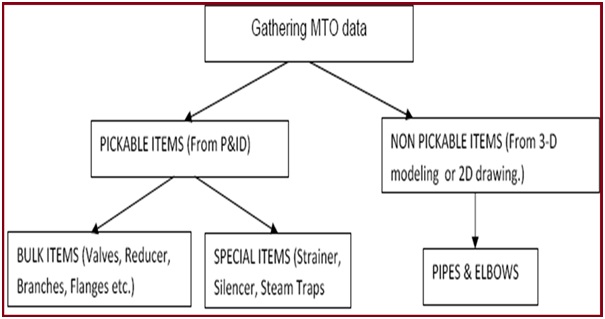

Fig. 1 below shows a flow diagram of how manual material take-off is generated. It is a time taking process and must be thoroughly checked as manual estimation is prone to errors.

Steps for Manual MTO Preparation

Manual Material Take Off is generated in the following steps:

- Make a folder of all P&IDs as a master copy for 1st Bulk MTO.

- All pick-able items are entered in an MTO format excel File, refer next sheet.

- All entries must be taken against a specific line number. In case a line number is not marked on P&ID, it has to be assumed by adding suffixes A, B, etc. with the main header line.

- Queries shall be raised for components that are not available in PMS. All such queries shall be documented & MTO shall be updated as & when queries are resolved.

- All assumptions made are documented & such items shall be marked as Hold. All assumed data is maintained in a separate file & tracked. MTO shall be updated whenever confirmed data is received.

- The basis of Material Take Off is a properly issued version of P & ID or documented communication.

Special Items in Material Take-Off Sheet

- Prepare the Piping Specialty Item index in a proper format.

- All special items (Strainer, Steam Trap, Sample cooler, Flame arrestor, Silencer, Sight glass, Special valves) shall be tagged in P& ID.

- Items like Safety showers, hoses, and couplings shall be given a common tag number distinctly.

- Prepare a datasheet having all Piping / Material data of special items.

- Send datasheet to process & related department for review & incorporating missing data & comments. All the missing data/information required to be filled by other disciplines shall be highlighted by the material team.

- Prepare IFP datasheet, when commented & updated datasheet is received.

Non Pickable Items

- Pipe Length & Elbows quantity is generated by 3-D modeling.

Generation of Total MTO

- Combine pick-able bulk items and non-pickable items (except piping special items)

- Combined data is processed and validated against the piping material specification (PMS).

- Check & Rectify errors.

- The final BOM (Bill Of Material) is received from the successful run file.

- Piping specials are processed separately

Preparation of Material Requisition

Material requisition for purchase includes:

- Bill of materials having commodity codes, sizes, material specifications, and quantity

- Additional technical requirements, inspection & test guidelines, documentation requirements, and guidelines for bid submission

- Receipt of quotations from prospective bidders and Technical Bid Evaluation

- Vendor offers are invited for the material requisition

- Received offers are evaluated to ensure technical compliance to material and project specifications

- TBE report is sent to the procurement department

- The purchase order is placed on a technically acceptable vendor after commercial negotiations

Vendor document review/approval

- After the purchase order is placed on a particular vendor, the vendor submits all the documents required per material requisition.

- These documents are reviewed and commented on to ensure compliance with all the specifications

- After the approval of the documents, the actual manufacturing of the material begins.

- Inspection and testing of materials are carried out at the vendor shop according to approved ITP/QAP

- Material is dispatched to the site after successful inspection and quality checks.

Normally every organization has its own standard format for each of the below-mentioned Material Take Off categories:

- Piping and Piping Component MTO

- Special Item MTO

- Insulation MTO

- Paint MTO

- Total MTO

Few more related Resources for you.

Introduction to Piping MTO, BOM, BOQ & MTO Stages

Piping Materials Take-off & Processing: An Overview

Piping Design Basics- Isometric Drawings

Role of a Piping Material Engineer

Hello,

first of all I’d like to say thanks very much for that wonderful topic, then I’d like to ask about MTO form or template if you have

thank you.

Mohammed Elbadri

Senior Projects Engineer

Thanks Sir…for sharing as it is useful