Whenever there is a need for moveable pipe connections, swivel joints are one of the solutions. They allow to move or rotate one part/component of the system relative to the other. This slow rotational movement provides very good flexibility to the piping system. In this article, we will learn about the basics of swivel joints, their applications, types, features, working, and selection.

What is a Swivel Joint?

A swivel joint is a precision-machined flexible piping component installed between pipes, hoses, or equipment. Their design allows one component of the system to move/rotate relative to the other. Industrial swivel joints are designed to work for an extensive temperature and pressure range. They have to ability to absorb external forces and generated stresses. Properly designed swivel joints have the ability to allow 360-degree rotation in 1, 2, or 3 planes.

Applications of Swivel Joints

Swivel joints are used in various industries including

- Chemical and petrochemical industry

- Power plants

- Metal and mining

- Water preparation and municipal technology

- Pharmaceutical industry

- Food and drink industry

- Refining industry

- Test stands

- Cooling water supply and water treatment plants

- Hydraulic systems and pneumatics

- Ink and paint industry

- Brewing and distillation industries

- Automotive industry

- Recycling industry

- Loading equipment

- Aviation and shipbuilding

- Paper and wood industry

- Cryogenic industry

- One of the common uses of swivel joints is in marine loading arms.

Materials for Swivel Joints

Swivel joints are manufactured from a range of materials depending on application requirements. Some of the common swivel joint materials are:

- Carbon Steel

- Stainless Steel

- Aluminum

- Brass

- Ductile Iron

- Bronze

- Hastelloy

- Duplex Steel

- Monel

- PTFE Lined

Characteristics of Swivel Joints

The main characteristics of swivel joints are:

- They are compact engineered components.

- They provide tight Seals

- They have a protected bearing chamber

- Long-Life Bearings

- Easy Lubrication

- No Field Adjustment is Necessary

- They are rigid, safe, and sustainable

- Swivel joints are available in various sizes starting from 3/4 inches.

- They are usually produced in flanged, threaded, and butt-welded end connections.

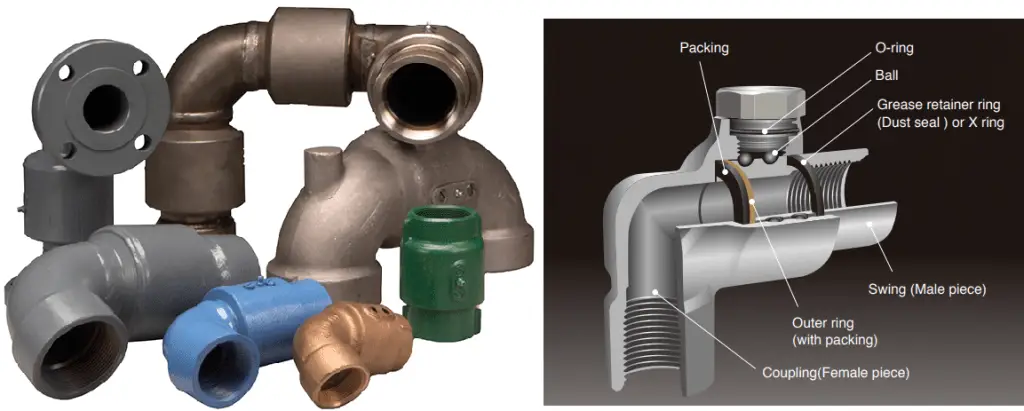

Working of a Swivel Joint

Swivel joints are usually made up of two main components; the sleeve and the body. They are locked in place by one or more ball-bearing races. These ball-bearing races keep the body and swivel sleeve properly aligned to allow the swivel to have a rotary motion around its axis. As the two parts of the swivel can rotate, the piping system components connected to the two ends of the swivel will also rotate freely and independently around the swivel’s axis. To have multiple axes of rotation, multiple swivels are installed with different orientations. This allows the system more freedom of movement between the sides of a fluid conveyance system. Different types of lubricants can be used to lubricate the bearing races.

The actual mechanical work is performed by the swivel’s ball bearings. However, the most important part of the swivel joint is the liquid-tight pressure seal that retains the pressurized working fluid. Pressure seals can be made from thermoplastics or elastomers like PRFE, FKM, Kalrez, fluoroelastomer, Chemraz, and nitrile rubber. The properties of these seal material options make them suitable for service with various fluids over a range of operating temperatures.

Types of Swivel Joints

Swivel joints can be categorized based on various parameters as mentioned below:

Depending on the end connection, there are three types of swivel joints

- Flanged swivel joint

- Threaded swivel joint, and

- Welded swivel joint.

Depending on the working component parts, swivel joints can be of three types:

- Compact O-ring swivel joints that use an o-ring for pressure seal.

- V-ring swivel joints that use a triple v-ring packing for sealing. They are robust in construction and suitable for severe applications.

- Split Flange swivel joints that use a separate bearing pack design with an H-ring and two O-rings.

Depending on the flow paths, there are basically three types of swivel joints:

- Straight through swivel joints having coaxial flow path.

- Right-angle swivel joints having outlet ports perpendicular to inlet ports.

- Offset swivel joints are a combination of both of the above designs

Depending on the axis of rotation, swivel joints are available in various styles which vary from manufacturer to manufacturer.

Selection of Swivel Joint

There are various parameters that must be considered for selecting a swivel joint for an application. Some of these factors are:

- Type of Fluid used

- Operating parameters of the fluid

- Space requirement

- Machining tolerances

- Insertion types like Seals, o-rings, wear rings, v-ring, bearings, etc

- Load requirements

- Environmental requirements

- Duty Cycle, torque requirement

- End connection requirement

- Material requirement, etc

Proper specification of swivel joint internal components is very important to reduce leaking possibilities. All parts must be designed based on recommended design guidelines.

Hi, thanks for your info on swivel joints

I am in need of 1″ swivel joint stainless steel that I want to use for water max 5-10 bar but I need to able to rotate it up to 1000 RPM

What would you recomend for use like that?

Regards

Arni