In the world of industrial processes, efficient and accurate information management is vital for smooth operations and optimal productivity. Process Datasheet is one such essential tool for all oil and gas projects. From engineering and manufacturing to oil and gas, process datasheets play a crucial role in ensuring seamless communication, facilitating equipment procurement, and driving effective decision-making. In this article, we will learn about the significance of process datasheets, their structure, and how they streamline operations in various industries.

Process datasheets are one of the important process deliverables generated during the detailed design phase of a project. Defining every piece of equipment is essential for every project and process datasheets quantify the equipment before procurement. Once the Process team prepares the P&ID (Piping and Instrumentation Diagram), the next phase is to create process data sheets for each piece of equipment. these process datasheets can be sent to suppliers or vendors to obtain pricing.

What Is a Process Data Sheet?

A Process Datasheet summarises the performance of equipment or a system. The technical characteristics of the equipment/system are specified in the process datasheet for initiating the detailed design. They are also known as Design Datasheets or Process Equipment Datasheets. All the fundamental technical requirements (Design Data) to specify equipment (technical specification) are provided in the process datasheet.

Process datasheets serve as a consolidated source of information about a specific component or equipment within an industrial process. These documents provide a standardized format for capturing key technical details, specifications, and operational requirements. Process datasheets act as a bridge between engineering and procurement teams, enabling effective collaboration and reducing the risk of miscommunication.

Understanding Process Datasheets

Structure and Components of Process Datasheets

Process datasheets for oil and gas industries typically contain the following sections:

General Information:

This section includes the equipment name, tag number, and a brief description of its function. It provides an overview of the equipment’s purpose and its integration within the overall process.

Process Parameters:

Here, critical process parameters are documented, including temperature, pressure, flow rates, and any other relevant operational variables. These parameters help in determining the equipment’s suitability for a specific process.

Design and Construction:

This section outlines the equipment’s design specifications, construction materials, dimensions, and installation requirements. It ensures that the procurement team can select the right equipment that aligns with the process needs and meets industry standards.

Performance and Efficiency:

Process datasheets highlight the performance characteristics and efficiency metrics of the equipment. This information assists in evaluating the equipment’s capability to meet production targets, energy efficiency goals, and overall process optimization.

Overall each process datasheet usually includes:

- Overall size of the equipment

- Number of equipment,

- Approximate geometry (Diameter, length, etc)

- Identification of the nozzle and tie-in point connections,

- Material of construction of the equipment (Material, Corrosion allowance, cladding requirement, lining requirement, etc)

- Full range of operating conditions (Design Pressure, Design and Operating temperature, Test Pressure, Fluid Type, etc).

- Specific notes and remarks.

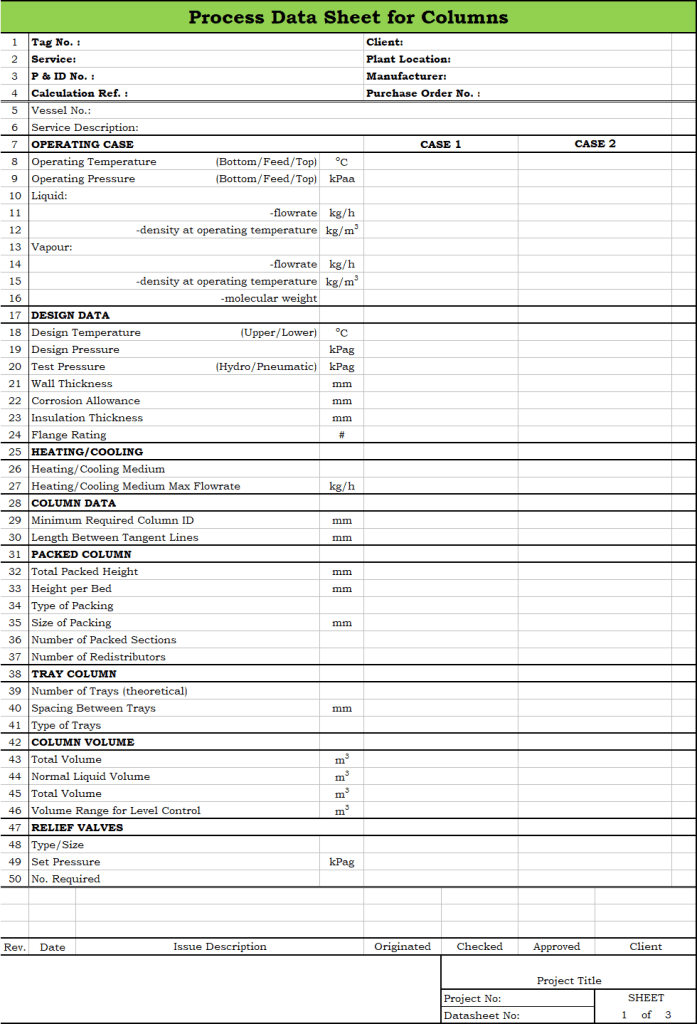

The Process Datasheet sometimes includes a simple diagram to easily communicate the technical specifications to the vendor, supplier, or clients. Mechanical datasheets for a piece of equipment are often prepared using the process datasheets as a reference. Fig. 1 below shows an example of a typical process datasheet template.

Significance and Benefits of Process Datasheets

Process datasheets offer numerous benefits as mentioned below:

Standardized Communication:

By providing a uniform format for technical information, process datasheets facilitate clear and concise communication between engineering, procurement, and maintenance teams. This reduces misunderstandings, accelerates decision-making processes, and minimizes project delays.

Streamlined Procurement:

Process datasheets play a vital role in equipment procurement by enabling precise specification and selection. Procurement teams can refer to these datasheets to identify vendors that provide equipment meeting the required specifications, reducing the risk of purchasing incompatible equipment.

Enhanced Safety and Compliance:

Process datasheets include crucial safety considerations, such as hazardous area classifications, electrical ratings, and necessary safety features. Adhering to these specifications ensures compliance with industry regulations and minimizes safety risks in the workplace.

Improved Equipment Reliability and Performance:

Process datasheets provide comprehensive information on equipment design, performance, and maintenance requirements. This knowledge enables better equipment selection and facilitates proactive maintenance planning, leading to enhanced reliability and performance.

Efficient Project Management:

Process datasheets are invaluable during the project management phase. They serve as a reference for design reviews, equipment installation, and commissioning activities, ensuring that projects progress smoothly and efficiently.

Applications of Process Datasheets

Process datasheets find applications across various industries. Some of the typical examples are:

Chemical and Petrochemical Industry:

In the chemical and petrochemical industry, process datasheets are extensively used for equipment procurement, such as pumps, reactors, heat exchangers, and distillation columns. These datasheets help in specifying material compatibility, corrosion resistance, pressure ratings, and other critical factors specific to chemical processes.

Oil and Gas Industry:

In the oil and gas sector, process datasheets play a vital role in the procurement and selection of equipment for exploration, production, refining, and transportation. Datasheets for equipment like compressors, separators, pipelines, and storage tanks provide crucial details about pressure ratings, materials, safety features, and environmental considerations.

Pharmaceutical and Biotechnology Industry:

Process datasheets are essential in the pharmaceutical and biotechnology sector, where strict compliance with regulatory standards is paramount. Datasheets for equipment like sterilizers, bioreactors, filtration systems, and cleanrooms outline critical parameters, such as sterility requirements, temperature control, agitation systems, and documentation protocols.

Power Generation Industry:

In the power generation industry, process datasheets are used for various equipment, including turbines, generators, boilers, and control systems. These datasheets provide specifications related to power output, efficiency, fuel requirements, emissions control, and safety features.

Manufacturing Industry:

Process datasheets find applications in the manufacturing sector for equipment such as conveyors, robotics, CNC machines, and industrial ovens. Datasheets in this industry specify parameters like speed, load capacity, precision, control systems, and energy consumption.

Generation of Process Datasheets

Even though the responsible engineer for preparing a process datasheet is a process engineer, it is jointly prepared by a process engineer and a mechanical engineer. Sometimes other disciplines like electrical and instrumentation may also help the process engineer in the process datasheet creation process.

Most design companies have their own standard process datasheet template for each type of equipment. So, while preparing the process datasheet for specific equipment, process engineers fill out the process data in those standard templates of process datasheets. Data like flow, temperature, pressure, capacity requirements, etc are obtained from the Process Flow Diagram (PFD), or process engineers calculate and fill the process datasheet. Equipment information like design code, loading information, flange and nozzle requirements, etc are usually provided by the responsible mechanical engineer.

Process datasheets vary from one piece of equipment to another. For static equipment, the data required will be different from rotating equipment. So, depending on the number of equipment in any project, different process datasheets need to be prepared. As the data from the process datasheet is used for the equipment design by the manufacturer, the data must be thoroughly checked and verified before sending to the equipment vendor. Process datasheet usually provides data for critical items in the equipment or system skipping the insignificant items.

The following documents are required for preparing a process datasheet:

- Process P&ID

- PFD

- Equipment Design Codes

- Process Design Basis

- Industry Guidelines and Best Practices

- Supplier datasheets, etc

Final Thoughts

Process datasheets are indispensable tools for efficient and streamlined industrial operations. By providing standardized and detailed information about equipment specifications, process parameters, and operational requirements, these datasheets enhance communication, aid procurement processes, improve safety, and optimize performance. Whether in the chemical, oil and gas, pharmaceutical, power generation, or manufacturing industry, process datasheets play a crucial role in facilitating informed decision-making, ensuring compliance with regulations, and driving operational excellence. Embracing the use of process datasheets not only enhances efficiency but also contributes to overall productivity and profitability in a rapidly changing industrial landscape.

Good article