Vents and Drains are required in piping systems to meet the Process, Construction, Testing, and Commissioning requirements. These are basically small tapping connections from the main pipes having a total length limited to 300 mm. These connections are with an isolation valve or without. Even though vents and drains are small connections in the piping system and are very often missed or neglected, they are very important and must be provided. Installing vents and drains after the pipe has been installed results in additional costs and an extended schedule. In this article, we will learn about Vents and Drains in detail.

What is a Vent and Drain Connection?

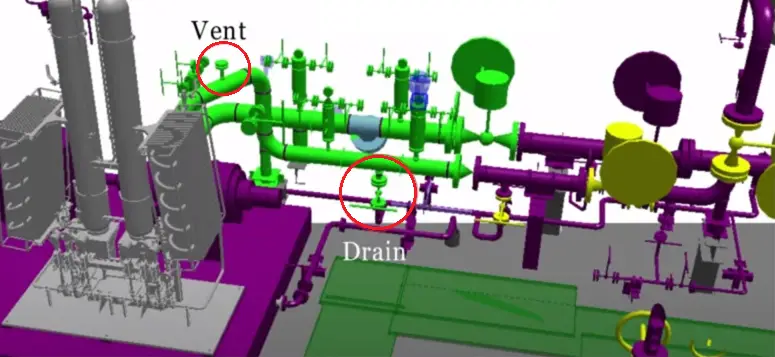

A vent is a piping connection taken from the top of the main pipe whereas a drain is the tapping connection taken from the bottom of the main pipe. In a piping configuration, vents are usually taken from the high point and that is why they are known as high point vents. Similarly, drains are considered in the low points and are popularly known as low point drains.

Types of Vents and Drains

Depending on the purpose of the vent or drain connection, vents and drains are classified into two groups.

- Hydrostatic test vents and drains, and

- Process vents and drains

Hydrostatic Test Vents and Drains

Hydrotest vent and drain connections are provided for use during hydrostatic leak testing. Hydrostatic vents and drains shall be provided only for the piping system subjected to the hydro test. Vent connections are located at high points and drain connections are located at low points of piping systems based on the physical piping configuration.

The main purpose of hydrostatic vents is to expel the air present in the pipe while filling the pipe with water for hydro-testing. If the air does not get a passage to be removed, it will be compressed inside the piping system, will cause an air bubble, and a pressure drop will occur. Also, water venting from high point vents will ensure the complete filling of water for starting the test. Once this is ensured, these vents are closed and pressurization starts.

The hydro testing drain connections are used to drain the water from the pipe after hydro testing is completed. During draining the vent connection is also kept open.

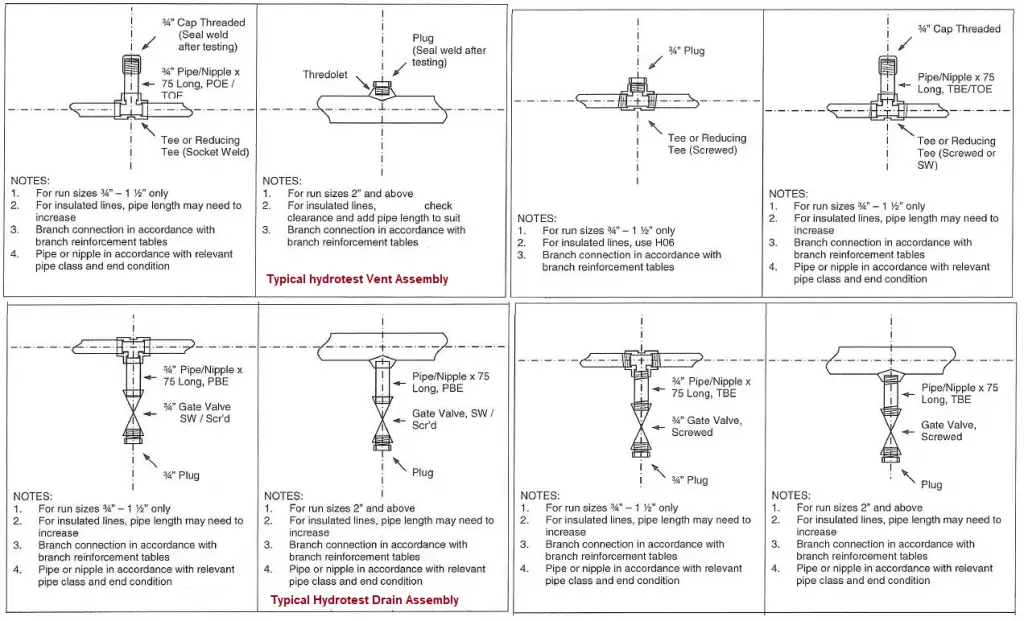

If the piping system is subjected only to pneumatic tests (e.g. instrument air, nitrogen system, etc.), then hydro-test vents and drains need not be provided. Fig. 2 below provides some typical hydro test vent and drain assembly details:

Hydrostatic test vent and drain features:

- Hydrostatic test vent and drain connections are not usually shown in the P&ID drawings but are shown in the detailed construction piping drawings.

- Hydrostatic drains are provided with an isolation valve but Hydrostatic vents are normally provided without valves. However, if valves are provided they shall be shown in the P&IDs.

- When Hydrostatic vents and drains are marked on the P&IDs, they are tagged as ‘HV’ & ‘HD’ respectively to differentiate from the process vent & drains. Access is normally not provided for hydrostatic test drains and vents.

- Hydrostatic vents shall be provided for line sizes 1½” and above Since line sizes 1” and below are considered to be self-venting. However, Hydrostatic drains shall be provided for all line sizes (including small bore piping).

- The hydrostatic vent & drain sizes and arrangement shall be as indicated in the piping standard drawing or stated in the project specifications.

- Hydrostatic vents not provided with valves, but with threaded plugs or end caps shall be seal welded after testing.

Process Vents and Drains

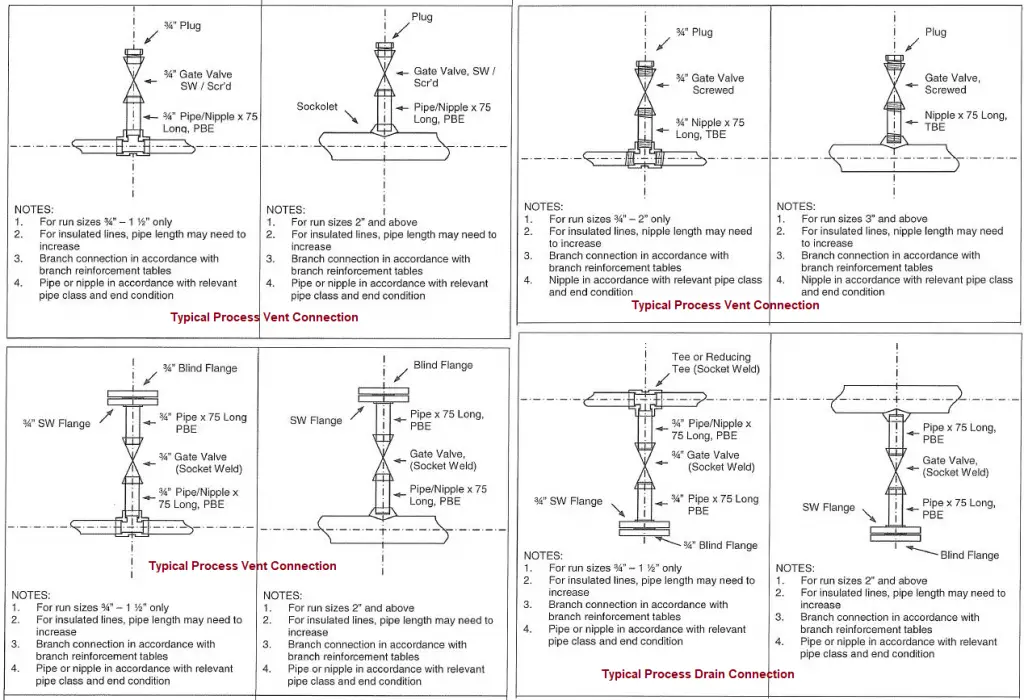

Process vent and drain connections are provided in piping systems for use during operation (start-up, shut down) or maintenance. These are provided for specific process requirements. These drain and vent connections are shown on the P&IDs and related detailed piping drawings. Process vents and drains are always provided with valves and are located such that they are easily accessible by operations or maintenance personnel. Once the venting or draining operation is complete, these valves are closed to continue the normal operation.

Process vents and drains are closed with suitable closure devices like plugs, caps, and blinds are sometimes connected to the vent/drain systems. On the pump discharge piping a drain connection shall be provided between the check valve and block valve to permit the draining of the line downstream of the check valve. This drain connection shall be indicated in the P&ID. Fig. 3 below shows some typical process vent and drain assembly details.

Characteristics of Vents and Drains

A Hydrotest drain shall not be provided if a line already has a process drain at the lowest point of the piping system. The process drain itself shall act as a hydro test drain in such cases.

A Hydrotest vent shall not be provided if a line already has an instrument connection (e.g. pressure/ temperature instrument) at the high point of the piping system. This connection itself shall act as the hydro test vent.

Adequate gussets/ bracings shall be provided to support the vents and drain in case of lines are subjected to vibrations.

Vents shall be avoided in control valve assemblies at elevated locations by using flat-side top reducers. The same is applicable to the outlet of relief valve lines with flat-side top reducers. During testing, the hydro tester shall provide a temporary spool with a vent connection in lieu of the control valve.

Depending on process requirements, hydro test drains may have to be connected to the drain system.

If there are service-specific drain systems like hot oil, hot water, etc., care shall be taken to connect the drains to the appropriate drain system.

Separate vents and drains shall be provided on the lines in a system if the piping specification or pressure class changes. With pressure break or class break, separate hydro-test packs are prepared, and hence separate vent and drain for the hydro test must be provided.

There are some cases where a hydrostatic vent may be required in the case of a vertical pocket or vertical pocket with a manual valve. Similarly, These are some cases where a hydrostatic drain may be required

Hello Anup Kumar Dey,

Well articulated and comprehensive article on Vents and Drains.

More to be compiled and added on Automatic removal of Air and Dissolved Gases from Venting and at Drain points in STEAM operation Space inside pipelines and vessel .

Also about Automatic Venting of Air from Cold and Hot Water piping systems in operation.

Do share your communication IDs for proactive discussions, should you desire.

Regards,

Homi R. Mullan

9820811308

mullan.hts@gmail.com

Hi , I am mech. Eng . We have a procedd piping L=90 m from : water , O2 , N2 , Ar .in horizontal arrangement . Where is best location for vent and drain connections ? If is nessacary redesign arranement to vertical ?

Dear Mr.Anup Kumar,

Due to height, no access to vent valve isolation. Is it possible to connect pipe to vent valve line and isolation valves installed at lower position, which is operation level on the ground?

Please advise.

If the matter is about the process concept, yes you can.

But if the usage is only for hydrotest, you can’t.

can you give more explanation, why in process concept we can and in hydrotest matter we cant?

Excellent post

Dear Mr. Anup,

Well article on Vents and Drains.

I have one question. If there is a tank with vent and drain both, the tank has valve on bottom and kept in sea.

So, the tank fills directly on basis of gravity no pump is used. Is there relation between vent or drain to adjust water filling (water level height) inside tank by gravity.

how did air vented off completely in pipeline of different elevation

Hi jee,

During hydro test it’s common everyone says every 10 metre 1 bar pressure drop can be accepted during hydro test.

Which standards in process Piping in 31.3 or it’s mentioned in some other standard please reply.

Sir can we take system drain tapping from pipe fittings example bottom of eccentric reducer?

Yea, we can take tapping from fittings.. but it is costly affair.. and should be avoided as much as possible…

What is the reference document for vent and drain philosophy? vent and drain philosophy is required for all type of fluid lines?

Dear Mr. Anup

Kindly provide the code number and clause no which give Design details of vent & drain in hydrotest?