In our last article related to FRP piping, we presented a brief introduction regarding the FRP pipes, their applications, properties, joining methods, FRP pipe fittings, Codes, Standards, Specifications, drawbacks, and differences between FRP pipes and GRE/ HDPE pipes. Click here to revise those points now and then proceed to read further. In this article, we will learn what are FRP pipes made of.

As the fiberglass-reinforced pipe is a composite material, it must be made up of a combination of two or more materials. The common materials used to make up the FRP pipe are:

- Fiber Glass Reinforcements

- Resin

- Fillers

- Promoters, accelerators, and inhibitors

- Pigments & UV stabilizers

The designer can create a wide variety of FRP piping that gives a broad range of properties and performance characteristics by,

- Selecting the right combination and amount of compositions.

- Manufacturing process.

Importance and Types of Fiberglass Reinforcements used for FRP pipes

Fiberglass reinforcement plays a major role in the mechanical strength of fiberglass pipes. The mechanical strength of an FRP pipe will increase by using more layers of fiberglass reinforcements. Different types of fiberglass reinforcements are as follows,

Surface Veils (SV):

- These are lightweight fiberglass reinforcement mats that permit high resin content with minimal reinforcement (glass-to-resin ratio of approximately 90:10).

- Due to the high resin content, it creates excellent chemical resistance at the pipe and fittings surface.

- It provides a smooth appearance for the surfaces of FRP pipe and fittings.

- This sort of fiberglass reinforcement is employed in the inner and outer layers of FRP pipe and fittings.

Continuous Roving (CR):

- Continuous rovings consist of bundled, untwisted strands of glass fiber reinforcement.

- Continuous rovings are utilized in the structural layers of filament wound piping.

- Because of the high glass content created by applying the continual rovings, It provides high strength in the direction of the fiber.

Chopped Strand Mat (CSM):

- This type of reinforcement utilizes short glass fibers, randomly oriented and held along with a resinous binder.

- Chopped strand mat provides good chemical resistance due to high resin and low glass ratio.

Woven Roving (WR):

- This kind of reinforcement utilizes glass fibers that are oriented in the 0° or 90°directions.

- Unlike chopped stand mats, the fibers are continuous and no binder is employed to hold the arrangement together.

- To maximize adhesion, woven rovings are used after chopped strand mat layers.

Types of Resins used for Fiberglass Pipes

Resins systems are divided into two basic groups which are thermosetting and thermoplastic. Fiberglass pipes and fittings use only thermosetting resin systems. Manufacturers/Purchasers choose a resin system based on chemical, mechanical, and thermal properties and the processability of flowing fluid.

The thermosetting resins fall into two general categories

- Polyester resins

- Epoxy resins

Polyester Resins:

Polyester resins are used to produce large-diameter sewage and water piping. Polyester resins have excellent chemical resistance. Manufacturers may select from different types of polyester resins that provide a good range of performance characteristics.

Epoxy Resins

Epoxy resins are generally used in the manufacturing of small-diameter piping (less than 30 inches). This type of resin will allow higher service temperatures compared to polyester resins.

Fire Retardant Resins

- All of the resin types (Polyester and Epoxy resins) are available in fire-retardant versions.

- These fire-retardant derivatives generally consist of bromine and antimony compounds to enhance the fire resistance property of resin.

Why Fillers are added to the manufacturing of FRP pipes?

Fillers are used as a volume substitute to reduce the resin cost. Inert fillers like hydrated alumina, glass microspheres, clay, talc, sand, calcium carbonate, and calcium silicate are used.

Fillers in FRP pipe can reduce shrinkage, add stiffness, control opacity, add fire retardancy and improve surface finish.

What are Promoters, accelerators, and inhibitors in FRP pipes?

Promoters and accelerators advance the action of the catalyst to reduce the processing time of FRP pipes and fittings. On the other hand, inhibitors control the cure cycle and increase the shelf life of the resin mix.

Why are UV stabilizers and pigments used in FRP pipes?

The pigments are added to achieve the specific color shade for FRP pipes. Ultraviolet stabilizers are imparts long-run resistance to the effects of sunlight and other weathering elements.

Online Video Course of FRP/GRP/GRE Pipeline Stress Analysis using Caesar II

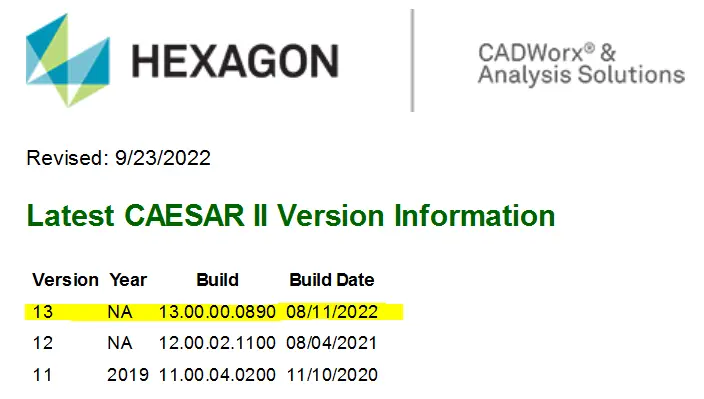

If you are interested in learning FRP/GRE/GRP Piping Stress Analysis using Caesar II software, you can have a look at the following online video course