Embarking on an interview for a Piping Layout Engineer position is an exciting step in advancing your career in engineering design. This role demands not only a solid foundation in piping design principles but also proficiency with industry-specific software and the ability to solve complex layout challenges. As a Piping Layout Engineer, you’ll be responsible for creating detailed piping layouts that ensure the efficient and safe operation of industrial systems. To succeed in your interview, it’s essential to demonstrate your technical expertise, problem-solving skills, and ability to collaborate effectively with other engineering disciplines.

In this blog post, we’ll explore some of the most common and challenging interview questions for Piping Layout Engineers. By understanding what interviewers are looking for and preparing thoughtful responses, you can showcase your qualifications and readiness for the role. From discussing your experience with design software to handling real-world problems and ensuring compliance with industry standards, this guide will help you navigate the interview process with confidence. Prepare to highlight your skills, share relevant examples, and convey your passion for piping design as you take this next step in your professional journey.

When interviewing for a position as a Piping Layout Engineer, you’re stepping into a role that requires a deep understanding of both engineering principles and practical design skills. So, here are some of the important questions every piping design engineer should prepare before attending any interview.

Piping Design Engineer Interview Questions

- What is the purpose of piping engineering?

- What are the common materials used in piping systems?

- What is the basic difference between pipe specifications A106 Gr.A, Gr.B, and Gr.C?

- Explain the difference between a pipe and a tube.

- From which size onwards is the nominal bore (NB) of a pipe equal to the outer diameter (OD) of the pipe?

- What is a piping isometric drawing? What data does a piping isometric drawing contain?

- What is a P&ID? What role does a P&ID play in the piping design process?

- Describe the function of a pressure relief valve. What should you consider when creating a piping layout for a PRV piping system?

- What factors influence the selection of pipe size?

- Name the pressure instruments used in chemical industries.

- What is a flange?

- How can flanges be classified based on face finish?

- In a typical tie-in, where should the spectacle blind be inserted?

- What is a swage nipple?

- What is the significance of the pipe schedule? What are the differences between piping schedule and pipe thickness?

- Explain the term “corrosion allowance.”

- What are weldolets, and when are they used?

- What is the purpose of a gasket in a piping system?

- What is the most commonly used material for gaskets?

- Where are smooth finish flanges and serrated finish flanges used?

- What are the different types of pipe fittings?

- What are the types of temperature measurement instruments?

- What is a valve’s Cv value and why is this important?

- Explain the difference between a ball valve and a gate valve.

- What are the basic functions of instruments in piping design?

- What is NPSH in pump terminology? How does it affect the piping layout?

- What is the need for a steam trap in a steam piping system?

- Describe the term “water hammer.” What is the impact of water hammer on piping design?

- What are the common types of welds used in piping systems?

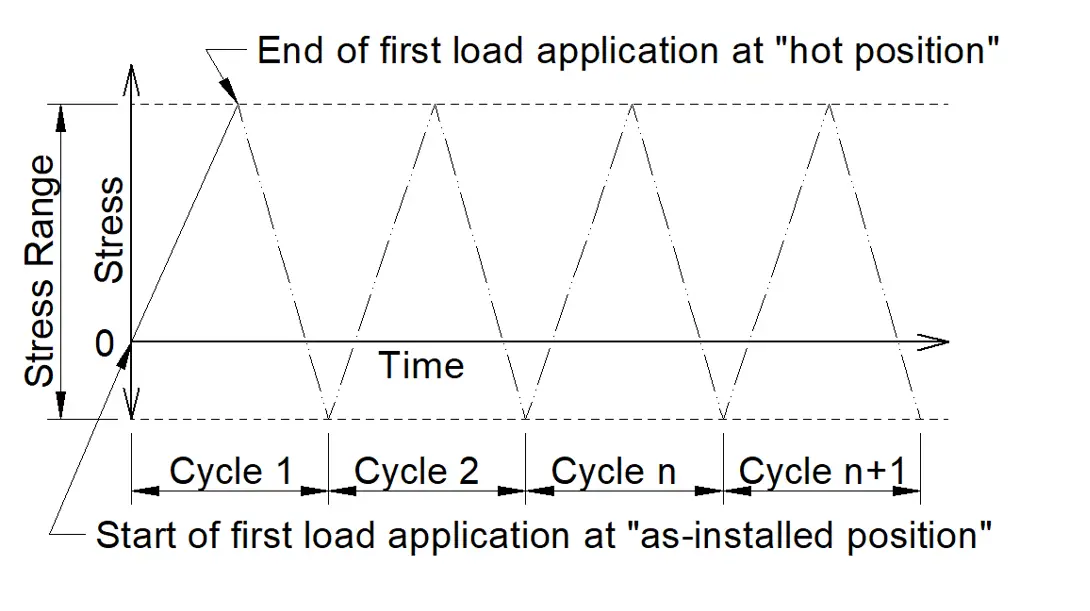

- Explain the importance of stress analysis in piping design.

- What is the purpose of a pipe support?

- What are the types of pipe supports?

- When should a spring hanger support be used?

- What is steam tracing, and why do we use it?

- What is the role of insulation in piping systems?

- Describe the function of an expansion joint in piping.

- What are the key considerations for underground piping layout?

- What is the difference between API and ASME standards?

- How do you select a flange for a pipeline?

- Explain the term “double block and bleed” in valve terminology.

- What would happen if we used concentric reducers in pump suction piping?

- What is a spool in piping?

- What is a model review, and what are its stages?

- What are the common causes of pipe vibration?

- What is the significance of a hydrostatic test? What is the test pressure?

- What is the basic difference between a hydrostatic test and a pneumatic test?

- Explain pump cavitation.

- Describe the function of a check valve.

- What is the meaning of design review? What is the role of a piping engineer in design review?

- Why do we use blind flanges in piping?

- What is the purpose of a reducer in piping?

- What is the purpose of an eccentric reducer and a concentric reducer? Can you give examples where eccentric reducers are used?

- What are the typical steps in piping design?

- Why do we use tees and crosses in a pipeline?

- What are the inferential methods of level measurement?

- Explain the importance of proper pipe routing.

- What is a blow-down?

- Can you draw a column piping from an overhead nozzle with all its supports?

- What is a jacketed pipe?

- When should you use a piping cap or a blind flange?

- What is the role of a piping engineer in a construction project?

- How do you design a rack?

- Describe the term “pipe rack.” What is the basic rule for placing pipes in a pipe rack?

- When all design parameters are the same, whose thermal expansion is higher among the following: a) Carbon steel, b) Stainless steel, c) Duplex steel, d) Cast Iron, e) Galvanized Carbon steel?

- How do you decide the number of tiers in a pipe rack?

- In what order do you arrange the pipes in a pipe rack, and why? How much of the area should be reserved for future expansion? Specify a range.

- What is the need for a loop in piping? How do you decide on expansion loops in a piping system?

- Explain the significance of flow velocity in piping systems.

- What is a piping class specification?

- What is the worst consequence of this layout in a steam piping system with a low pocket but no steam trap?

- What are the common methods of pipe bending?

- What is the need for a drip leg in a steam line?

- What is the meaning of the term “slug flow”? How does it impact piping design?

- A P&ID illustrates the specification break that occurs between carbon steel and stainless steel (at a flange). What additional arrangements do you need to make for that dissimilar material flange joint?

- What is the purpose of a strainer in a piping system? What are the different types of strainers used in piping system design?

- What is the need for a high-point vent and a low-point drain in a piping system?

- Explain the importance of non-destructive testing (NDT) in piping.

- How many types of piping specialty items do you know? Why are they called piping specials? Why are they not included in standard piping specifications?

- What are the common causes of pipe corrosion?

- What is a pressure-temperature rating, and why is it important?

- Describe the term “pipe flexibility analysis.”

- Draw a typical steam trap station layout and explain why the existence of a bypass line around the trap is not a good idea when the condensate is returning to a condensate header.

- What is a pipe trench?

- What are the difficulties in routing U/G piping with respect to A/G piping?

- What are the types of compressor drives?

- In a power plant inside a process refinery, where exactly does the ANSI B31.1 and ANSI B31.3 scope break occur?

- An air fin cooler (with two air coolers, each having two inlet nozzles) needs a typical piping arrangement. How many types of piping arrangements are possible?

- What is a valve trim composed of?

- Which American standard is referred to for the selection of the following piping elements: A) Flanges, B) Butt Welded fittings, C) Gaskets, D) Socket & Threaded fittings, E) Valves, F) Pipes?

- How can piping flanges be classified based on pipe attachment?

- What is the temperature limitation for carbon steel pipe material?

- Can we use ASTM A 106-B for a temperature of -35 Deg C? If so, at what condition?

- How are the pipe fittings classified based on end connections?

- Which type of piping materials are used for drinking water, instrument air, etc.?

- What are the differences between a long-radius elbow and a short-radius elbow?

- Why are welded pipes preferred over seamless pipes?

- What are the criteria for taking a branch connection from the main pipe?

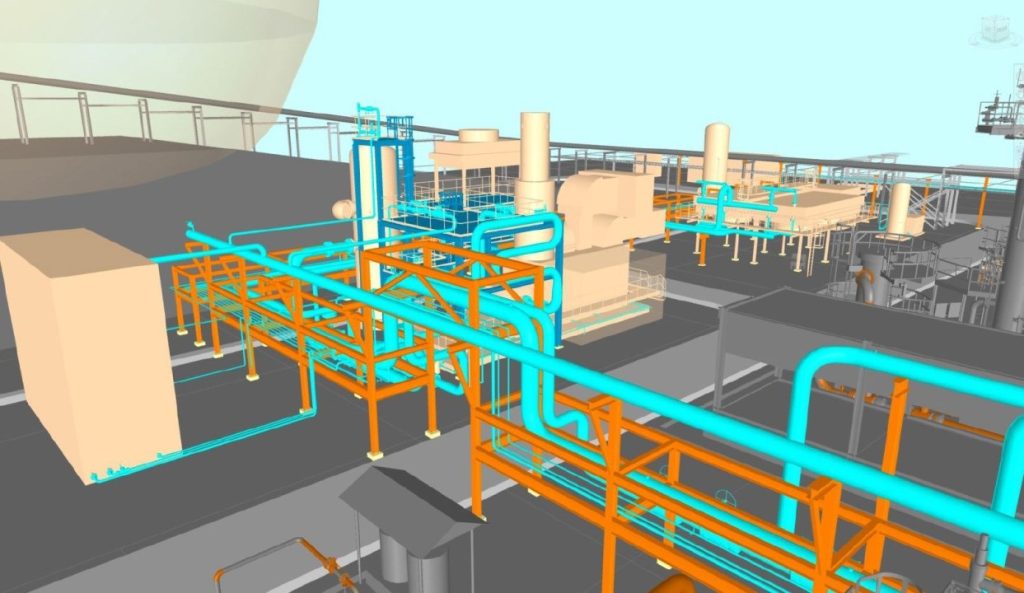

- Explain the role of 3D modeling in piping layout design.

- How far apart should two pipe welds be kept from one another?

- What do you mean by ‘PWHT’? Why is it required?

- What is the meaning of pipe support spacing? What is the basic span of supports for 2”/6”/10”/24” pipe?

- What is the meaning of a plot plan, and what are the criteria for designing it?

- Draw a typical layout of tank piping with its supports.

- What are the common issues related to pipe routing, and how do you mitigate them?

- How is the piping to the tank inlet nozzle supported, and why?

- What is the function of providing the anchor, cross guide, and guide for piping?

- Can you draw a typical piping layout for a shell and tube heat exchanger piping? Where do you provide anchors and slotted support for heat exchangers?

- When do you use clamped-pipe shoes? How do you decide the length of a pipe shoe support?

- What are the stages involved in Plant design?

- What care shall be taken while doing the layout for the end suction-top discharge horizontal-type centrifugal pump piping?

- What care shall be taken while routing piping for instruments?

- What is the meaning of equipment layout?

- Draw a piping routing for a top suction and top discharge pump.

- How do you calculate the width of a pipe rack?

- How do you interact with other departments? With which disciplines do you have an interface??

- What is a line routing diagram?

- What is the importance of pressure drop calculations in pipe sizing?

- How do you handle a situation when the client changes design requirements mid-project?

- What care shall be taken while doing the layout for the pump piping?

- How do you ensure the ease of access for maintenance during the design phase?

- Draw a pump suction piping arrangement from a storage tank outlet with proper support.

- What is an adjustable type of support, and why is that important?

- Can you calculate the Man-Hour required for piping design work? What is your basis for calculation?

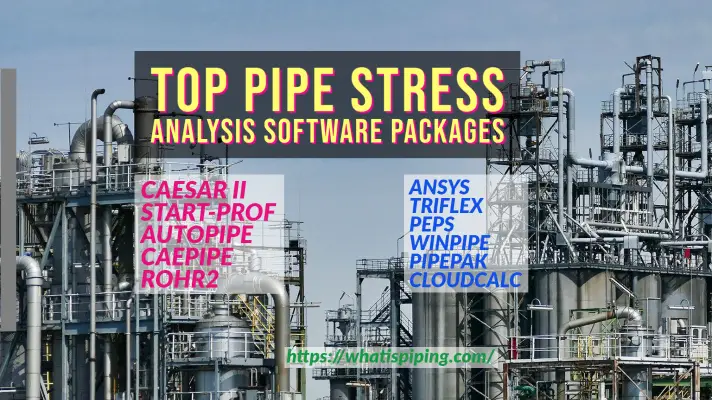

- What software programs have you used for piping design purposes?

- Which software is best for piping design: E3D or SP3D, and why?

- Can you draw a piping arrangement for a steam turbine piping?

- What are the considerations for pipe routing from a reciprocating compressor?

- How do you account for thermal expansion and contraction in your designs?

- What is the process of designing pipe supports, and what factors influence their placement?

- What are the key components of a piping design specification?

- How do you handle pipe routing through congested or tight spaces?

- How do you track progress in large-scale piping design projects?

- How do you manage a team of engineers and designers for a piping layout project?

- Can you describe a situation where you had to resolve a conflict between the engineering team and the client?

- How do you manage the handover process from design to construction?

- What is the significance of NFPA codes in the design of piping systems, particularly in hazardous areas?