Butterfly valves belong to the quarter-turn rotational motion valves family and are used primarily to stop, regulate, or start the flow. The term “butterfly” in a butterfly valve is actually a disk that is connected to a rod. When this rod rotates the disk by 90° the butterfly valve opens or closes. Butterfly valves are popular in the industry because of their lightweight, fast operation, and low costs. These valves use handles, gears, or automatic actuators for operation as per the requirement.

Smaller-size butterfly valves usually have manual operation whereas larger devices are normally motorized. With high flow capacities, butterfly valves enable the use of smaller units that reduces weight, cost, and space requirement significantly. With only two wetted parts and a range of valve linings, butterfly valves isolate the body from the flowing media which eliminates the need for expensive exotic materials.

The smooth contoured, crevice-free disc produces lower torques, while the design of butterfly valves makes them easy to install, maintain, and service.

Butterfly Valve Uses

The use of Butterfly valves is broad and wide. Some typical applications of butterfly valves are in the water supply, wastewater treatment, slurry services, fire protection, air and gas supply, vacuum services, lubrication system, chemical and oil industries, fuel handling systems, power generation, compressed air and gas services, steam services, food processing, pharmaceutical, marine systems, and sanitary valve application. Basically, Butterfly Valves are suitable for use in

- Constant Load Applications

- Space-Restrictive Applications

- Throttling Valves

Components of a Butterfly Valve

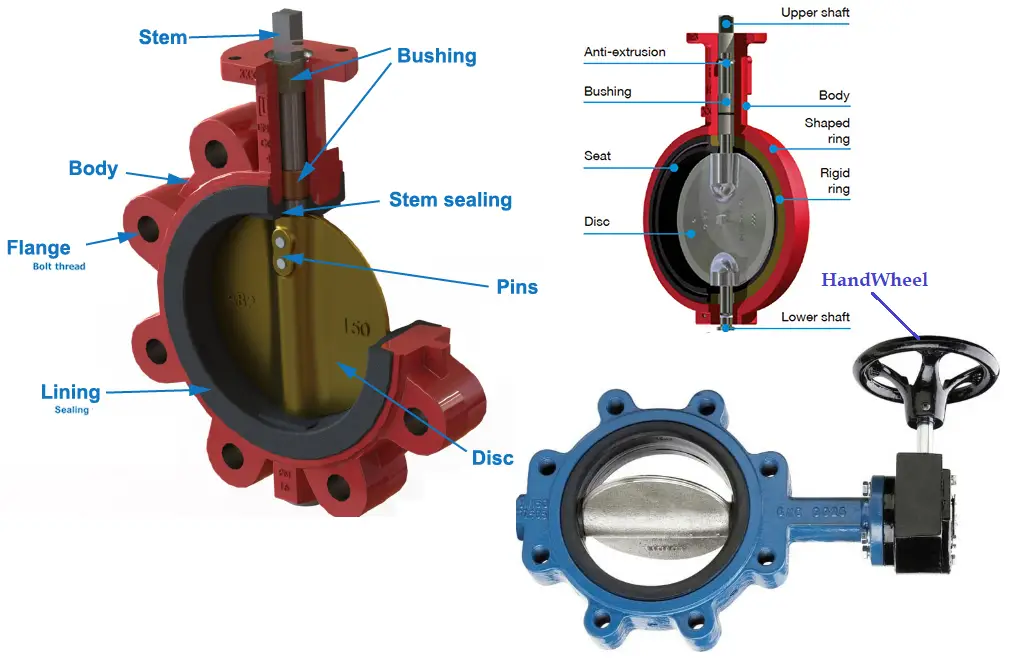

There are four main components in a butterfly valve: body, disk, stem, and seat.

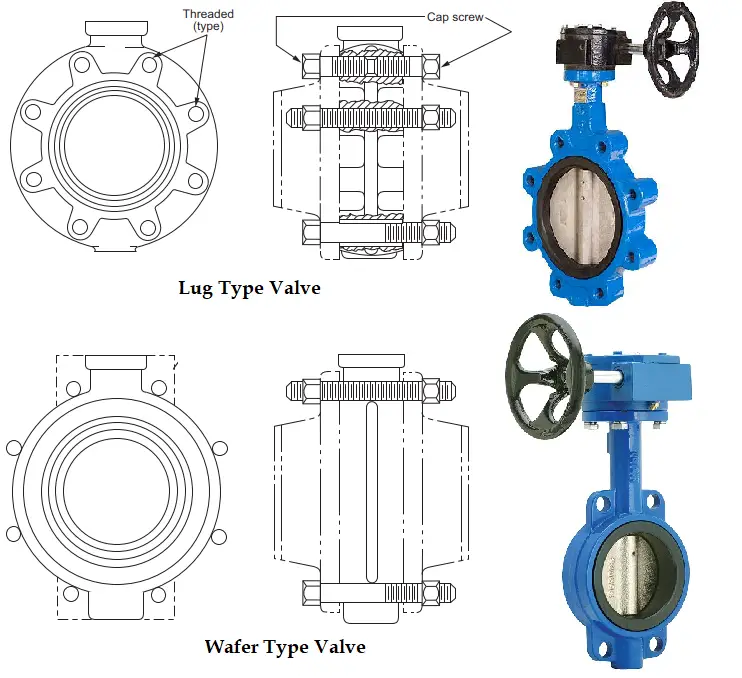

Valve body: the body of the Butterfly valves fits two pipe flanges, the most common body design is the lug and wafer type (Fig. 2).

Butterfly valve disk: The disk (disc) is the element that stops the flow. For improving flow, sealing, and operating torque, There are variations in disk design and orientation.

Valve Stem: The stem of the butterfly valve consists of a one-piece or two-piece shaft design. Stem design shall prevent galling potential between similar corrosion-resistant materials.

Butterfly valve Seat: To provide shutoff, the seat of a butterfly valve utilizes an interference fit between the disk edge and the seat. The seat may be bonded, pressed, or locked into the body.

The seat of the butterfly valve is an area that has various designs based on manufacturers. A single-piece flexible PTFE seat is a popular choice. The significance of the single-piece seat is that there are no O-rings or metallic springs to limit the temperature or corrosive conditions that the PTFE seat can be exposed to. With the application of the line pressure, the full cross-section of the seat is pressurized causing the seat to follow the natural deflections of the disc under pressure.

Advantages of Metal Seats in Butterfly Valves

Metal seats in the butterfly valves have various advantages and should incorporate the following:

- good tightness

- no jamming

- smooth control

- low torque

- wide temperature range

- low cavity relief

- good corrosion resistance

Functions of a Butterfly Valve

The main functions of a butterfly valve are

- Flow regulation: Flow can be easily controlled or regulated simply by turning the valve wheel.Using a flow controller the process can be automated.

- Flow Isolation

- Prevention of Backflow: Butterfly valves can be used for backflow prevention in some situations.

Types of Butterfly Valves

Depending on disc closure design, connection design, and actuation method, Butterfly valves can be categorized into several types.

- Based on the Disc Closure Design

- Concentric Butterfly Valve

- Eccentric Butterfly Valve

- Single-Offset

- Double Offset

- Triple Offset

- Based on the Piping Connection

- Lug type

- Wafer Type

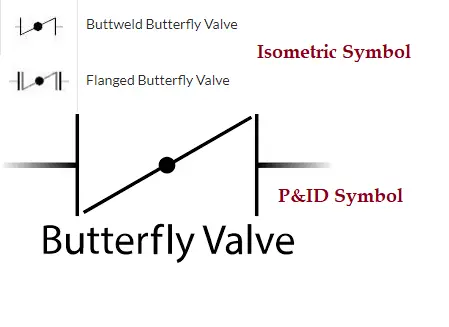

- Flanged Butterfly Valve

- Butt-welded Butterfly Valves for high-pressure applications

- Based on the Operation method

- Manual Actuation

- Lever Operated

- Gear Operated

- Automatic Actuation

- Electric

- Pneumatic

- Hydraulic

- Manual Actuation

- Based on Seat Material

- Soft Seated

- Metal Seated

Concentric Butterfly Valve

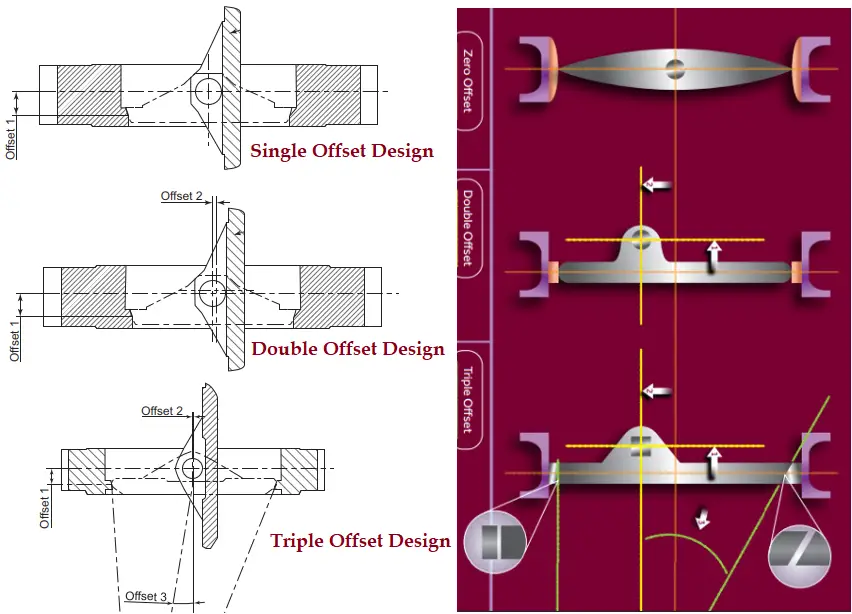

The concentric butterfly valve is the most basic type of butterfly valve design. In this design, the valve stem passes through the centreline of the disc. This is also known as a zero-offset valve. Concentric butterfly valves are used for low-pressure services.

Eccentric Butterfly Valve

In an eccentric butterfly valve, the stem does not pass through the centerline of the disc. There are three types of offset valves.

- A Single-offset valve is the butterfly valve where the stem is located right behind the centreline of the disc.

- In a double-offset butterfly valve design, the stem is located behind the disc with an additional offset to one side.

- For highly critical applications, a triple-offset butterfly valve is used. The third offset is in between the disc and seat contact axis. This design results in minimal seat contact thus very less wear and is highly efficient.

Lug Type Butterfly valve

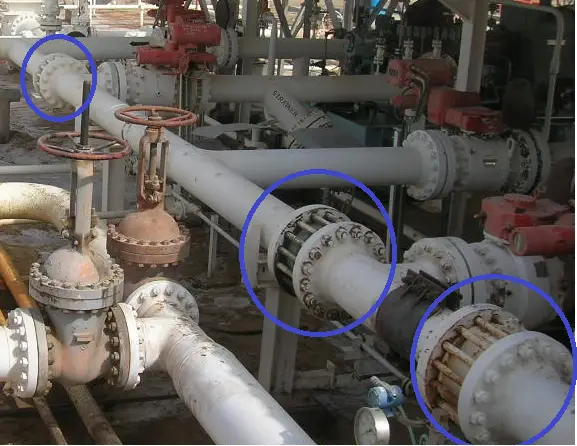

The lug-style butterfly valve (Fig. 2) designs have threaded lugs outside the valve body. Using two sets of studs, the valve is connected with piping flanges. One end of the line can be disconnected without affecting the other side since each flange has its own bolts.

Wafer Type Butterfly Valve

A wafer-type butterfly valve is sandwiched between two pipe flanges and the flange bolts surround the valve body. This is the most economical butterfly valve. Long bolts are used to cover both flanges and the valve body. A wafer butterfly valve provides sealing against bi-directional pressure differences in the fluid flow. The wafer version of the butterfly valves is designed to protect against a tight seal and two-way pressure difference.

Wafer vs Lug Style Butterfly Valve

There are some distinct differences between the Wafer-type and Lug-type butterfly valves. The following paragraphs explain the same.

Lug-style butterfly valves use threaded tapped lugs to mount the valve to piping flanges using bolted connections. On the other hand, wafer-style butterfly valves don’t have attachment lugs. Usually, they have four holes to align with the connected piping. The valve is clamped in between two piping flanges.

A lug-style butterfly is suitable for end-of-line service but wafer-style butterfly valves can not be used for end-of-line services. In case there is a maintenance requirement on the line having water style butterfly valve, the entire line needs to be shut down.

Wafer-style butterfly valves are lighter and cheaper as compared to lug-style butterfly valves.

Butterfly Valve Sizing

The size of butterfly valves used for control purposes is not dictated by the pipe’s nominal diameter. The size is determined based on the operating characteristics to achieve correct control characteristics. To determine the size, the opening angle characteristics should be considered. Typically, some butterfly valves are designed with approximately equal percentage characteristics over an opening of 600.

The maximum working capacity is decided based on the body rating or the seat shut-off capability whichever is lower.

Butterfly Valve Advantages

Butterfly Valves provide many advantages as compared to other valve types.

- Compact design; little space requirement.

- Lightweight; easily supported by the piping system.

- Less raw material and less costly.

- Quick operation; less opening or closing time.

- Easy to Install.

- Simple operation due to low operation torque.

- Available in very large sizes

- Improved energy efficiency

- Low-pressure drop and high-pressure recovery

- Long valve life

- Relatively inexpensive to build.

- Less number parts; Hence, reduced maintenance.

- Butterfly valves are suitable for control purposes with linear flow characteristics between 300 and 700 openings.

- Butterfly valves offer excellent rangeability from 30:1 to 100:1.

Disadvantages of Butterfly valve

However, there are a few disadvantages of a butterfly valve as listed below

- Throttling service is limited to low differential pressure

- Disc movement is affected by flow turbulence.

- The valve disc is always under pressure and can interrupt the flow even in an open position.

- The possibility of Cavitation and choked flow is a concern

- Poor Sealing function.

- Not suitable for high differential pressure.

Butterfly Valve vs Gate Valve

The main differences between a butterfly valve and a gate valve are tabulated below

| Butterfly Valve | Gate Valve |

| Butterfly valves provide obstructed flow even in a fully open position. | The flow of gate valves is unobstructed in the fully open position. |

| Handling and installation of butterfly valves are quite easy. | The handling and installation of gate valves are comparatively difficult. |

| Due to their smaller size butterfly valves need reduced space. | As gate valves are bigger in size, more space is required to install them in a piping system. |

| Butterfly valves possess the comparatively less pressure-withstanding capability. | Gate valves are suitable for high-pressure applications. |

| Due to the quick operation of butterfly valves, there is a possibility of a water hammer. | As the gate valve operating time is more, there is less chance of surge. |

| Butterfly valves have a shorter shaft that is easily accessible. | Gate valves possess a longer shaft with difficulty to access. |

| Due to the smaller size, the weight of butterfly valves is significantly less. | Gate valves are heavy-weight valves. |

| Butterfly valves are cheaper. | Gate valves are quite expensive compared to butterfly valves. |

Ball Valve vs Butterfly Valve

The main differences between a butterfly valve and a ball valve are produced below in a tabular format.

| Butterfly Valve | Ball Valve |

| Butterfly valves are disk-mounted. | Ball valves are ball-mounted. |

| Pressure drop through butterfly valves is usually more. | Ball valves provide less pressure drop as compared to butterfly valves. |

| Less sealing. | More effective Sealing. |

| Butterfly valves are lightweight. | Ball valves are significantly heavier. |

| Butterfly valves require less installation space. | Ball valves need more space to install. |

| Butterfly valves are less costly as compared to ball valves. | Ball valves are costly items as compared to butterfly valves. |

Symbols of Butterfly Valves

The following symbols are used as butterfly valve symbols in piping isometric and P&ID.

Butterfly Valve Standard

Industrial Butterfly valves are designed based on the following butterfly valve standards

- API 609

- MSS SP-67

- BS EN 593

- ISO 5752

- MSS SP-68

- AWWA C504

Butterfly Valve Materials

The following materials are normally used for butterfly valve components

| Butterfly Valve Body | Disc Material | Stem material | Seat material |

| Carbon Steel | Aluminum | Cast Steel | Neoprene |

| Stainless Steel | Stainless Steel | Stainless Steel | PTFE |

| Cart Iron | EPDM | ||

| Ductile iron | NBR | ||

| Cast Bronze | Viton | ||

| DSS | BUNA-N | ||

| Nickel Alloy/Hastelloy | Inconel (Metal Seat) | ||

| Titanium Alloy | Stainless Steel |

Data to be Provided for Butterfly Valve Manufacturer

The following data should be provided to the butterfly valve manufacturer while ordering

- Flange rating/Pressure

- Specific gravity, viscosity, material content, and the composition of the fluid to be handled.

- Pressure drop or required Cv (maximum)

- Flow rate

- Design and operating temperatures

- Piping moments

- Valve body, Disc, Seat material

- Valve plate material

- Valve diameter or connected pipe diameter

Butterfly Valve Working Principle

The butterfly valve operates based on the quick shut-off principle. The circular disc (butterfly) of the valve is placed in the center of the pipe which allows a rod to go through it to an actuator, on the outer side of the valve. Using the handwheel, the metal disc is rotated to keep the disc parallel or perpendicular to the flow and it allows or closes the flow. So, the operating principle of the butterfly valves is fairly simple. The animation below by the GEMU group clearly shows the butterfly valve working.

Butterfly Valve Manufacturers

There are many butterfly manufacturers in this world. A list of a few of the world-renowned butterfly manufacturers is provided below:

- Dezurik

- Pentair Valves and Controls

- Flowserve Corporation

- Fisher Valves

- Flomatic Valves

- Crane Company

- NIBCO

- Bray Valves

- Zwick

- Kitz Corporation

- Hobbs Valve

- Apollo Valves

- Kieselmann

- Valworx

- Davis

- Velan

- Emerson Electric Company

- L&T Valves

- Cameron

- Amco Industrial Valves

- VIP Valves

Properly selected and integrated with the latest controls and communications technology, butterfly valves can provide an economical, long-term solution to flow control in large process plants, the power industry, refineries, pulp, and paper manufacturing, and food and beverage processing.

Butterfly valve super

How can we give solutions to customers for centric valve with PTFE lined with pressure rating design and working PN16.

Sir,i want to ask you about maximum allowable operating pressure for flanges,what is this, how it is different from design pressure,how to calculate withstand pressure it can able to take?Kindly guide me.

Thanks for sharing such an informative blog. Lots of my doubts are clear after reading your post. I am also dealing in butterfly valves. We, EG Valves offer the best quality industrial valve. I think you should approach them!