Pipeline Construction means laying the pipes to serve their intended purposes. There are two kinds of pipelines: Liquid and Gaseous. The construction of both pipelines is similar. The construction of large-scale cross-country pipelines involves a multitude of activities.

The construction of a pipeline can be compared with a moving assembly line. A large pipeline construction project is usually broken into manageable lengths called “spreads,”. Each spread is attacked at a time utilizing highly specialized and qualified workgroups. Each spread consists of various crews having their own responsibilities. As one crew finishes its work, the next crew takes its position to complete its piece of the pipeline construction process.

Pipeline construction steps usually take years to complete. Many surveys, studies, and plans are required to be completed before the construction of the pipeline starts. A comprehensive plan addressing the societal, developmental, environmental, and safety considerations are prepared to build the pipeline.

Pipeline Construction Steps

The construction of pipelines is a multi-step process. Many months prior to the actual pipeline construction phase, planning and surveys are conducted. Pipeline Construction steps can broadly be classified into the following three categories:

- Pipeline Pre-Construction Activities

- Pipeline Construction activities and

- Pipeline Post-Construction Activities

Pipeline Pre-Construction Activities

Pipeline pre-construction activities shall include the following:

- Reconnaissance Survey

- Detailed Engineering Survey

- Permits and Clearance

- Cadastral Survey

- Acquisition of Right of Way (ROW)

- Acquisition of Land for Repeater Stations and Block Valves

- Approval of QA/QC procedure

Reconnaissance Survey

The main objectives of a Reconnaissance survey in pipeline construction are

- To establish the pipeline route

- To avoid populated areas, forest, and mining areas

- To keep the number of crossings to a minimum

- To ensure easy approachability to the ROW

- The utilization of existing ROW if any.

The reconnaissance survey is carried out by the following activities:

- Desktop study of Survey toposheets

- Site visits covering major control points

- Geographical Information System (GIS) packages

Information from the reconnaissance survey include

- Route map in 1: 10,000,00 scale

- Field data like altitude, terrain, cost of building materials

- Type and number of important crossings

Detailed Engineering Survey for Pipeline Construction

Detailed engineering survey for pipeline construction involves the following activities:

- Route Survey

- Ground Profile Survey

- Crossing Details

- Collection of hydrological data

- Collection of data on the type of terrain, soil, and crop pattern

- Soil Resistivity Survey

Data available from detailed engineering survey include

- Route maps in 1: 50,000 scale

- Profile maps in 1: 25,000 scale

- Crossing details in 1: 200 scale

- Soil Resistivity Report

Permits and Clearances for Pipeline Construction

General Permits required for pipeline construction are:

- Railways

- Roads

- Canals and drains

- Panchayats

- Other Agencies

Statutory Permits required for pipeline construction are:

- Environment & Forest Clearance

- State Pollution Control Board Clearance

- Chief Controller of Explosives

Cadastral Survey for the pipeline construction route

A cadastral survey of the construction pipeline route involves the collection of the following:

- Collection of village maps

- Transfer of IPs/TPs and marking of 18 meters. width of ROW on the village maps

- Identification of plots falling under the proposed 18 meters ROW marked for acquisition

- Calculation of plot areas

- Collection of land owner’s name and addresses

- Collection of land rates, crop yield, and rates for different crops

Acquisition of ROW for pipeline construction

- The positioning of land acquisition personnel and notification of Competent Authority

- Preparation and Notification of land schedule

- Serving Notice to landowners

- Hearing objections from landowners

- Preparation and notification of schedule

- Award and disbursement of compensation

Compensation

- Land compensation @ of 10% of land cost

- Crop compensation

- Standing crops

- Presumptive crops

- Preparation of notification for termination operation in respect of the lands and notification of the same

Pipeline Construction Activities

Pipeline Construction Activities can be broadly classified as below:

Front End activities for pipeline construction:

The front-end activities for pipeline construction are listed below

- Opening of ROW

- Clearing and grading

- Hauling and stringing

- Trenching

- Bending

- Welding & Radiography

- Joint coating

- Lowering

- Backfilling

Back End activities of pipeline construction:

The back-end pipeline construction activities are

- Tie-ins

- Crossings

- Hydrotesting

- Valves installation

- Final cleanup and restoration

- Installation of pipeline markers

- Documentation

- Clearing and Grading Operation:

- Stacking of ROW.

- Marking of ROW boundaries.

- Clearing of trees, bushes, farm crops, undergrowth, and routes, electrical and telephone poles falling within the 18 M width of ROW.

- The grading of ROW is sufficient to be consistent with the maximum permitted pipe bending radius.

- Providing ramps, diversion at road crossings, hume pipe culverts for maintaining water flow across the ROW.

Hauling and Stringing of pipes

- All care shall be taken for transportation of the pipes from the coating yard to the ROW without damage to the coating and pipe.

- Stringing shall be done in such a manner that pipes are easily accessible and shall not hinder the movement of equipment.

- In rocky areas, pipe stringing shall be done after rock trenching.

- Stringing shall not be done for more than 10 km ahead of trenching.

- Pipes of special grades or wall thickness shall be strung at the required specific locations.

Trenching for laying pipelines

- The pipeline shall be laid at a distance of 5 meters from one edge of the ROW.

- Stacking of trench line.

- The width of the trench shall be equal to the pipe diameter plus 400 mm.

- The depth of the trench shall be equal to the diameter of the pipe plus 1 meter.

- Extra width and depth shall be provided in rocky terrain.

- Stripping of the topsoil up to 30 cm of the trench and storing separately.

- Suitable crossings for the passage of men, equipment, cattle, etc. shall be provided.

Bending of pipes

- The bending of the pipe is required to negotiate changes in the vertical and horizontal alignment of the pipeline.

- The bending procedure has to be approved before bending pipes

- Cold field bends shall only be used

- The radius of bends shall be limited to 40 D for pipes up to 18” dia and to 60 D for pipes of 20” and above.

- Welding seams are to be kept in the plane passing through the neutral axis of bending.

- Tangents of a minimum of 2 M in length are to be left at both ends of the pipe.

- Check for ovality, thinning, wrinkles, and buckles.

Welding of pipeline

- Welding procedure specification has to be prepared for approval of the procedure and qualification of the welders as per API 1104.

- Welding is done using a vertical down technique with cellulose-coated electrodes.

- An internal line-up clamp shall be used for proper alignment of the joint.

- Initial weld: Root/ stringer bead.

- 2nd run: hot pass to reinforce root bead.

- 3rd/ 4th run Fillers;

- 5th: Capping

Radiographic inspection of pipelines for pipeline construction

- Radiographic inspection is carried out by using X-rays.

- Visual inspection of all welds shall be carried out by a qualified welding inspector having minimum qualification of Level – II certification.

- All joints at the following locations shall be radiographed.

- Initial 1 km.

- At cased road/rail, submerged crossings,

- Tie-ins (including golden tie-ins)

- Marshy areas.

- Valves and insulating couplings

- 20% of balance mainline joints(100% here)

Field Joint Coating

- 250 mm on either side of the pipe is left uncoated in the coating yard to facilitate welding.

- The width of the sleeve shall depend upon the cut-back length provided in the yard-coated pipe.

- Heat-shrinkable sleeves are used for coating welded joints.

Joint Coating procedure

- The pipe surface is sandblasted to SA-21/2 specification.

- The sandblasted area is heated up to 600C and the epoxy primary is applied on the surface.

- The sleeve is wrapped around and then shrunk on the joint using a propane/ LPG torch.

- Air bubbles trapped are removed using hand rollers.

- The integrity of the joint coating is tested by conducting a peel test.

Lowering of Pipeline in the trenches for Pipeline construction

- The excavated trench should be free from excess earth, rock, hard clods, and other debris.

- The coating of the pipe string shall be checked for damages by using a holiday detector.

- Repair of coating damages.

- Sand padding and rock shield are provided in rocky areas before lowering.

Backfilling of Pipeline

- Backfilling shall be done immediately after lowering.

- Backfilling shall be done with earth free of hard lumps, boulders, rock, etc.

- Sand padding over the pipe shall be provided in rocky areas.

- Slope breakers shall be provided in steep gradients to avoid the washout of the trench.

Pipeline Construction Tie-ins

- Situations in the mainline such as rail/ road/ river crossings etc. may cause a break in the continuity of mainline laying operation and are normally bypassed by the mainline laying crew.

- The process of connecting the unconnected sections of the pipeline is defined as a tie-in operation.

Crossings in Pipeline construction Route

Type of Crossings:

- Open cut :Roads, cart tracks, and minor watercourses.

- Cased :Railways, National Highways, and State Highways

- Submerged crossings :Major rivers

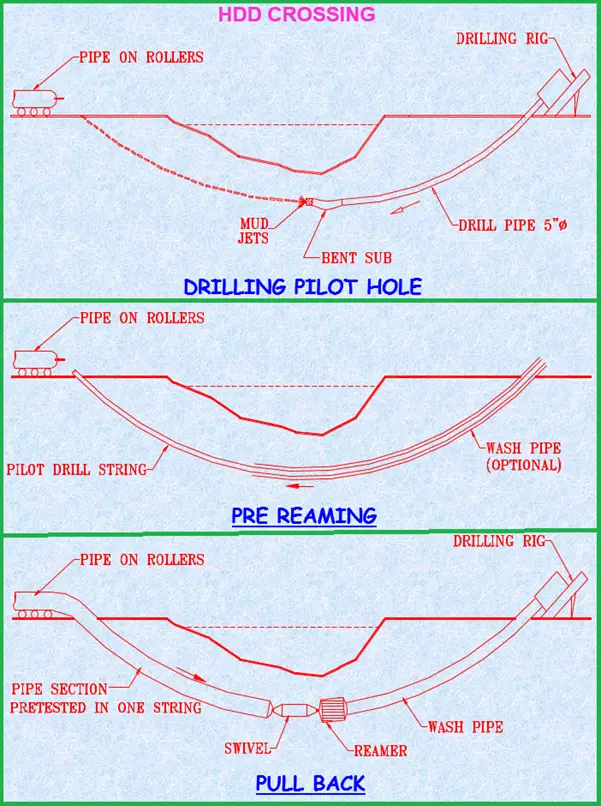

- HDD crossings :Perennial rivers and canals

HDD CROSSING:

Hydrostatic Testing of Pipeline during Pipeline construction

Objectives for Hydrotesting

- To establish that the pipeline has the required strength for which it has been designed.

- To demonstrate leak tightness of the pipeline.

Parameters for choosing test sections

- Availability of water

- Suitable place for disposal

- Ground profile

- Logistics

Pipeline Hydro-Test procedure:

- Air cleaning the pipeline to clear all debris and muck

- Gauging

- Water filling with corrosion inhibitor

- Thermal stabilization

- Pressurization

- Evaluation and acceptance

Pipeline Valve Installation

- Block valves are either Hand operated or Motor operated.

- Mainline isolation valves are provided at an approximate interval of 25 to 35 km. depending upon the size of the line.

- Isolation valves are provided on either side of major rivers.

- Tapings for the pig signaler and pressure transmitters are provided at the valve locations for monitoring the pressure, temperature, and moment of the pig.

Final clean-up, Restoration, and Installation of Markers

- After construction, ROW is leveled and restored to the entire satisfaction of the landowners/ authorities.

- All drains, utility lines, and water lines damaged during construction are restored to their original position.

- Pipeline markers such as kilometer posts, turning points/ direction markers, warning signs, and boundary pillars are provided.

- ROW is notified for closure.

- Payment of crop compensation.

Documentation of Pipeline Construction Activities

All pipeline construction activities must be documented for future reference purposes. The following should be maintained

- Daily logbook

- Separate register for each activity

- Pipe Book

- Welding inspection report

- Radiographic inspection report

- Tie-in charts

- Pipe damage register

- Deviation/ NCR register

- Equipment & manpower mobilization report

- Hydrostatic testing register

- Claims register

- Due to deviations

- Due to a change in the work plan

- Damage to pipes etc.

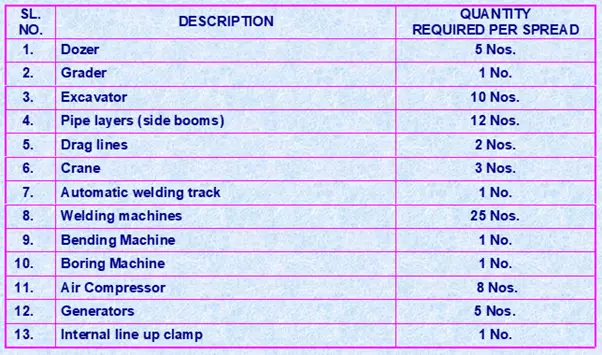

Major Pipeline Construction Equipment

List of major equipment required for construction:

Pipeline Post-Construction Activities

Post-construction Activities of pipelines construction shall include the following:

- Caliper survey

- Line preservation

- Cathodic Protection

- Commissioning

Caliper survey:

- A caliper survey establishes the geometric integrity of the pipeline constructed and helps to establish base data for future reference.

- Helps to eliminate un-noticed pipe defects during construction.

Preservation:

- The constructed pipeline is preserved when there is a substantial lag between mechanical completion and actual commissioning.

- Preservation is carried out by water filling the pipeline with suitable dosages of corrosion inhibitor.

Cathodic Protection:

- Temporary Cathodic Protection to the pipeline is provided by using sacrificial anodes during the construction period.

- Permanent Cathodic Protection of the pipeline is provided with the impressed current after construction and during the operation of the pipeline.

- Click here to know more about cathodic protection

Commissioning of Pipeline

After the mechanical completion of the pipeline, the line is commissioned after the completion of the following activities.

- Commissioning and making ready for the pumping and delivery stations.

- Obtaining various permits and clearances.

- Arranging products.

- Click here to know more about pipeline start-up and commissioning activities

Hello Anup, your blog is quite to the point and impressively presented. Can you recommend any book or online courses for beginners in the pipeline industry? I am a mechanical engineer but have no knowledge about pipeline, and I am searching for resources that can explain things in a more simpler manner via books or online courses.

Useful content.

Thanks

Thanks ANUP

I am also a mechanical engineer,I also have handle alort on piping engineering in Oil and Gas. You are very vast in piping construction, I must commend your efforts and knowledge

Dear

Very Nice & USeful Blog.I have doubt in NDT Progressive sampling for RT. How to implement this.explain

Merci beaucoup pour tous les détails sur la tuyauterie industrielle . C’est un métier que j’apprécie beaucoup et j’ ai augmenté quelques connaissances sur les codes et autres .

Dear sir

I want to do pipeline course.

Useful description, thanks

Its very useful blog for Pipeline,Thanks for sharing.

Very good Information, thank you very much.

Anup, very good information, I believe its covers a wide SOW and can be used as a good guide- in-fact I am using certain elements of it to create a WBS for a project we have upcoming.

The content is very educative especially for the newbies.

Thank s for sharing

Good day

Quite impressive Blog and its layout.

Clearly you are a passionate and experienced pipeline engineer.

I have done lots of Bulk Water and nothing on Gas.

Will like to keep the connection

Excellent and thanks a lot …This will become a guideline for every pipeline engineers. Great work

As a piping engineer, I don’t stop learning from experts like you. As such i want to belongs to this group.

my contact is +2348023321389.

Excellent and concisely written guidelines.