Piping Materials are a very important part of Piping Engineering. The success of a project and the cost to a great extent depends on piping materials. Hence, the proper selection of pipe materials plays an important role in the project economy, and it is always preferred to choose piping materials that meet all technical requirements but are cheaper. There is a wide variety of piping materials present in the market. Choosing the best and most economical pipe material for a specific service is really challenging and here comes the role of piping material engineers. They, in consultation with process engineers, decide the right kind of pipe materials. In this article, we will explore the types of piping materials and their selection philosophy.

Piping material is a broad term and is not limited to only the material of the pipe. It signifies the material of all piping components; pipes, fittings, valves, and other items. So, in a sentence, we can say that piping material means the materials of all the components that are present in a specific pipe class.

Parameters for Pipe Material Selection

As pipes and pipelines carry various liquids and gases having different process conditions, the proper selection of pipe material is very important. The main process parameters that govern the piping material selection process are:

- Types of Fluid to be handled (Flammable, Explosive, Corrosive, Reactive, Volatile, or Hazardous to human skin).

- Design and operating temperatures. (Whether the temperature of the fluid is low temperature, high temperature, or cryogenic)

- Design pressure of the fluid.

- Flow medium

- Service Life of the Fluid Handling System

- Material characteristics

- Fracture tendencies at the temperature extremes

- Corrosion and erosion

- The environment where the pipe will be working

In addition to the above parameters, some non-process parameters that are considered for pipe material selection are:

- Cost of the pipe material

- Availability

- Manufacturability, Weldability, etc.

Various piping codes and standards provide a long list of acceptable piping materials under their jurisdiction. These codes provide various details about those piping materials like design rules, allowable stresses at different temperatures, etc.

Pipe Material Selection Basics

Selection of basic Piping Metallurgy and Material (viz. CS, LTCS, AS, SS, etc.) for piping specification lies with the Process/Metallurgy Engineer. The main selection is based on process, licensor, and/or intrinsic metallurgy requirements to suit process medium, like corrosion, high temperature, pressure, etc.

This basic selection shall also address special considerations for PWHT, special valve trim for NACE, corrosive services like acids, amines, etc., and hazardous services like Hydrogen, Chlorine, Phosgene, Oxygen, etc.

Piping Material Basics

Metals are rarely used in their purest form as they have low mechanical strength. Alloying helps increase its properties like strength and ductility. (Easiest eg. is adding Carbon to Iron to produce ferritic Carbon Steel). Addition of alloying elements in proper proportions along with appropriate metal processing and heat treatment results in the optimization and improvement of its mechanical properties. Alloying also helps in improving corrosion & oxidation characteristics, machinability, weldability, etc.

Complex alloyed material is also being engineered for use in aerospace programs and applications. Metallic glasses and crystalline alloys have also been developed and metal alloys are sometimes even bonded with graphite, ceramic, and organic materials as composites for wider and more complex applications

Mechanical Properties of Pipe Materials

Certain mechanical properties are also considered while selecting pipe material for a specific service. They are

- Modulus of Elasticity (Young’s Modulus) – the ratio of stress to strain and measured using tension tests

- Elastic range: Material returns to its original shape after the load is released

- Plastic range: Material is permanently deformed even after the load is released

- Yield Strength – It defines the transition from elastic to plastic phase and it establishes the limiting value at which this transition occurs

- Ultimate Tensile Strength – This defines the limit to which any further addition of load under constant strain would arrest the specimen elongation or thinning and would result in its failure.

- Ductility – expressed in the elongation of a specimen and its reduction in the cross-sectional area before its failure. Established by measuring specimen length before elongation and minimum diameter before failure.

- Hardness – Ability of a material to resist deformation. Hardness is tested by Brinell or Rockwell Hardness tests, both of which are indentation-type tests

- Toughness – Ability of a material to resist sudden and brittle fracture due to the rapid application of loads. Measured using the Charpy V-Notch test.

- Fatigue Resistance – Ability of a material to resist failure or crack initiation and its further propagation under repeated cyclic loading conditions

Material Terms and Definition

Before diving into the actual piping material selection process, let’s learn some of the important terms relevant to pipe materials.

- Creep Strength – Ability of a metal to withstand constant weight or force at elevated temperatures without yielding

- Brittle fracture – Sudden & rapid failure of a metal due to the application of energy with hardly any deformation

- Stabilization – Addition of alloying elements to prevent carbon-chromium precipitation and formation of carbides, which reduces corrosion at higher temps

- Intergranular Corrosion (IGC)– Corrosion occurring at grain boundaries of metals due to the depletion of chromium by the formation of the Cr Carbide layer, after reacting with carbon, which protects from further corrosive environments. (Min 12% Cr in SS). IGC is caused by reducing acids, oxidizing acids, and organic acids

- Reducing acids – In Chemistry reduction means loss of oxygen and gain of Hydrogen – examples are Hydrochloric acid, Hydrofluoric acid, and hydrobromic acid

- Oxidizing acids – Oxidation (a chemical reaction between metal & Oxygen) means a gain of Oxygen and loss of Hydrogen – examples are Sulfuric acid, Nitric acid, and Chromic acid

- Organic acids – are of the carboxyl (COOH) group containing hydroxide (OH) – examples are Acetic acid, Formic acid, Citric acid

- Stress Corrosion Cracking (SCC) – Failure of metal through a combined action of tensile stress and chemical corrosion. SCC also depends on service temp, solution environment, exposure duration, and metal properties

- High-Temperature Hydrogen Attack – Results in the degradation of Carbon and Low Alloy Steel due to depletion (decarburization) of carbon (strengthening agent) in steel due to reaction with Hydrogen at high temps, thus causing loss of strength in metal.

- Hydrogen Blistering – A low-temperature phenomenon where atomic hydrogen diffuses into steel and is trapped as non-metallic inclusion, which builds up pressure and eventually bulges and blisters steel.

- Hydrogen-Induced Cracking (HIC) – A phenomenon similar to hydrogen blistering but HIC occurs in pipelines operating in sour services. Hydrogen blistering and HIC can be controlled by restricting sulfur content in steel to 0.005% or 0.010% max.

- Oxidation – The chemical reaction of metal and alloys with oxygen in the metal in the air, to form oxides is called oxidation. This process results in scaling.

Effects of Alloying Elements on Metallic Piping Materials

The main alloying elements that influence the properties of pipe materials and hence their selection are

- Carbon (C) – More carbon means more strength and hardness but less ductility and toughness.

- Phosphorus (P) – High content decreases shock resistance & ductility, making the material brittle.

- Silicon (Si) – Increases high-temperature properties, making the metal more stable by increasing tensile strength without increasing brittleness when under 2%. It also resists oxidization & is used as a deoxidizing agent

- Manganese (Mn) – It improves hot working characteristics by increasing hardening when combined with sulfur

- Nickel (Ni) – It improves hardenability by increasing the strength and toughness of steel. Combined with Chromium it improves impact and fatigue resistance. Improves low-temperature properties. Higher nickel content improves resistance to chloride cracking

- Chromium(Cr) – It is a hardening element & improves material strength at a higher temp. Improves high temp oxidation & corrosion resistance of steel

- Molybdenum (Mo) – It makes the steel harder and more stable by increasing its creep resistance at a higher temp. 2% Mo in steel also reduces high temp oxidation rate

- Columbium/Titanium (Cb/Ti) – Commonly used stabilizing elements to improve sustained high operating temp properties of steel by reducing carbide precipitation. SS Type 321 and 347

Typical Pipe Material Selection Criteria

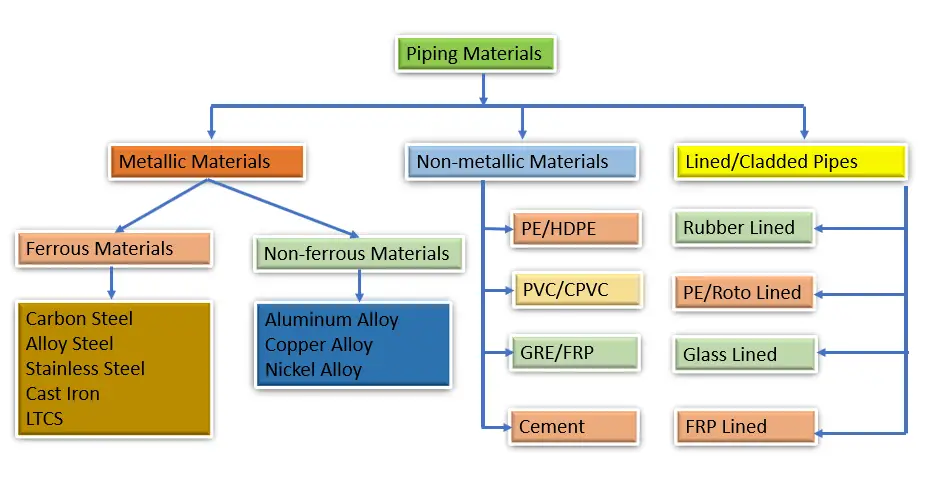

Now selecting a proper pipe material is a difficult task as there is a wide variety of pipe materials available in the market. Piping materials can broadly be of three types

- Metallic Piping Materials

- Non-metallic Piping Materials, and

- Composite Piping Materials

Metallic pipe materials can again be subdivided into two groups; Ferrous piping materials and non-ferrous piping materials.

Composite pipe materials consist of both metals and non-metals.

Types of pipe materials can easily be graphically represented as shown below:

Cast Iron (CI) ASTM A126, A436 Pipe

The usual features of Metallic Cast Iron pipe materials are given below:

- Metallic Cast Iron/Ductile Iron/Malleable Iron Pipes are brittle, low-strength materials used for low-temperature applications and basic utilities like air, water, drains, etc. Low-cost material.

- CI shall not be used on severe cyclic condition services, excessive heat, thermal shock

- DI & MI cannot be used at a temperature below -29° C & above 343°C (ASTM A47, A536)

- Austenitic DI (ASTM A 571) may be used at temp up to -196°C max but not lower

Carbon Steel (CS) ASTM A53-B/A106-B/API 5L-B Pipe Selection

The usual features of Carbon Steel Metallic Piping materials are

- Better than CI and has higher strength.

- Used for higher temperatures (up to 800° F or 427° C).

- Most process services include steam piping.

Low Temp Carbon Steel (LTCS) ASTM A333-Gr 1, 3, 4, 6, 8, 11, etc

- Used for low-temperature services like chilled brine, chlorine liquid/gas, propylene, etc. (Bet -45°C to 485°C)

- Has more Carbon and no alloying elements like Cr and Mo and contains Nickel which improves low-temperature properties

- Impact properties/values at low temp are better than in CS (Charpy N Notch test)

- Refer to ASTM 01.01 for impact test requirements for low-temperature/cryogenic services

Galvanized Carbon Steel Pipe

- Use limited to about 200° F or 93° C for basic utilities like water, air, nitrogen

- Normally piping connections are screwed to avoid damage to galvanizing due to welding

Lined Piping

- Normally metallic, glass, non-metallic, cement-lined piping

- Used for highly corrosive services like acids, caustic, process limited services, etc.

- CS Cement lined pipe normally used in seawater applications

Alloy Steel (AS) – Also known as Cr-Mo Steel Pipe Selection

- Used for high-temperature applications in CS base like process services, superheated steam, reformer gases, etc. above 400° C design temp (ASTM A335 Gr P1, 5, 11, 22, etc.)

- C-1/2Mo steel can be used bet -29°C up to 454°C design temp

- Cr-1/2Mo steels can be used bet -29°C and up to 550 to 600°C

- PWHT or stress relieving is a must after welding

Metallic Stainless Steel (SS) Pipe – Austenitic Grade Cr-Ni-Mo

The main characteristic features of metallic stainless steel piping are

- Used for high-temperature and process-critical services and for cryogenic applications

- Selection governed by the process for specific service needs

- ASTM A312 Gr TP 304 and 316 are normally used SS grades for pipes

- The presence of 2% Mo in SS316 gives better overall corrosion resistance properties than SS304

- SS316 has a higher resistance to pitting and crevice corrosion in chloride environments

- Grade L series has lower C (0.035%) which improves its use for higher temp up to 1100°F (600°C), has a higher resistance to IGC and better weldability, Better mechanical strength at elevated temps & good high temp oxidation resistance up to 925°C.

- Grade H – Controlled C between .04 to 0.1% & lower Ni provides improved high-temperature strength above 815° C.

- Common applications of SS304 are food, steel utensils, beverages, the dairy industry, etc.

- Common applications of SS316 are food, pharma, marine, medical implant steel, etc.

- Grade 317 – use dictated by licensor/process

- Grades 321 and 347 are metallurgically very stable in high-temperature applications because of the addition of Columbium and/or Tungsten

- Impact testing is not required if C < 0.1%

- Refer to ASTM 01.01 for impact test requirement for low-temperature/cryogenic services

Exotic Grades – Not commonly used – High cost!!!

Duplex SS: Grade 2205/2207 (UNS No. S31803/32760)

- Cr-Ni-Mo steel

- Has excellent strength & corrosion resistance, improved resistance to acids and chlorides, and good weldability (ASTM A928)

Nickel 200/201: (UNS No. N02200/N02201)

- Pure Nickel-very good mechanical properties

- Excellent resistance to corrosive media

- Good mechanical strength at a high temperature

- Good ductility at low temp, good weldability

- Nickel 201 has a little more Carbon than 200 which makes its use ideal for highly corrosive caustic soda (Sodium Hydroxide) applications up to 300°C (ASTM B163).

Monel 400/500: (UNS No. 04400/05500)

- Ni-Cu Alloy – ASTM B165

- Good resistance to saline and acidic conditions

- Ideal for high-velocity seawater/brackish water applications

- High resistance to cavitation and corrosion

- Monel 400 has oxidation resistance up to 550°C

- Monel 500 has higher tensile strength and hardness and resists oxidation up to 650°C

- Ideal for use with H2SO4 and other acids

- Ideal material for valve trims

Inconel Pipe Selection

Inconel 600/601: (UNS No. N06600/06601)

- Ni-Cr-Fe Alloy – ASTM B167

- Excellent oxidation and scale resistance properties up to 1200°C

- Excellent resistance to corrosive media

- Good weldability and is resistant to chloride stress corrosion cracking

- Inconel 600 is used extensively in power plants Higher Cr content in Inconel 601 offers better oxidation and carburization resistance to sulfur applications

Inconel 625: (UNS No. N06625)

- Ni-Cr-Mo-Fe Alloy – ASTM B705

- Excellent strength and ductility between 700°C to 1100°C

- The presence of Mo further increases corrosion resistance at higher temperatures

- Ideal for phosphorus acids, organic acids, seawater, boiler tubing, etc.

- Good weldability

Inconel 800: (UNS No. N08800)

- Ni-Cr-Fe Alloy – ASTM B407

Inconel 800H: (UNS No. N08810)

- Ni-Cr-Fe Alloy – This is a solution heat-treated high carbon version of Inconel 800 with improved elevated temp properties and strength

Inconel 825: (UNS No. N08825)

- Ni-Cr-Mo-Fe Alloy – ASTM B423

- High resistance to sulfuric acid, phosphoric acid, solvents, reducing acids, and seawater

- Cupro Nickel: C70600, ASME B466/B467, B111Is an alloy of Cu & Ni, Cu 70-95% & Ni 30-95%

- Has very good corrosion resistance, especially to seawater applications

- Good mechanical strength & weldability

- B466 seamless and B467 welded pipes are used in marine applications like seawater piping and fittings

- B111 used in exchanger/condenser tubes

- Also used extensively in the automobile industry, especially for brake tubing

Hastelloy C276: (UNS No. N10276)

- Ni-Cr-Mo-W Alloy – ASTM B619/622

- Best alloy for extremely corrosive conditions

- Good for reducing and oxidizing applications

- The presence of Tungsten (W-Wolfram) imparts excellent resistance to strong oxidizing services, hot contaminated acids, solvents, chlorides, etc.

- Ideal for strong acids, formate acids, acetic hydride solutions, seawater, and saline solutions.

- Corrosion-resistant to wet HCL, hydrochloride solutions, etc.

Alloy 20: (UNS No. N08020)

- Ni-Cr-Mo-Cu Alloy – ASTM B464

- Excellent mechanical properties, strength, and machinability

- Excellent stress corrosion resistance to boiling 20-40% Sulfuric acid

- Widely used in 98% Sulfuric acid service for valve trims

- Ideal in food & pharma applications where product purity has to be guaranteed

Aluminum and Al Alloy Pipe (ASTM B345)

The main features of Aluminum and Aluminum alloy metallic piping materials are:

- Excellent mechanical properties like strength, weldability, and formability

- Good surface finish

- High corrosion resistance

- Used in Gas & Oil transmission and distribution piping systems

- Also used in aircraft applications as it is light but strong

Titanium: ASTM B861 – Seamless Pipe/ ASTM B862 – Welded Pipe

Metallic Titanium piping materials have the following features:

- These are practically pure grades of Titanium with about 6% Nitrogen

- Has high strength, impact toughness, fabricability, formability, and weldability

- Exceptional corrosion and erosion resistance which allows

- Zero corrosion allowance

- Used a lot in aerospace applications and engine components besides chemical, marine, refinery, chlorine, food processing, and pharma applications

Non-Metallic Piping Materials

The most common non-metallic piping materials are PVC, UPVC, CPVC, PP, LDPE, HDPE, PVDF, HALAR, PTFE, PFA, FRP, RTRP, etc.

Polyvinyls as Pipe Materials

- (PVC, UPVC, CPVC) ASTM D1784/1785

- Polyvinyl Chloride (PVC) is the most common material for plastic pipe

- Unplasticized (U-PVC) is the same as PVC but has resins added as additives to make it harder

- Service temp up to 60°C (140°F)

- Joining methods are solvent welding, threading, or flanging

- Chemically inert, good corrosion and weather resistance, high strength, good electric and thermal insulator

- Used in chemical processing, chilled water distribution, chemical drains, etc.

- Not suitable for oxidizing agents like concentrated sulfuric acid, nitric acid, esters, and amines

- Polyvinyls will burn but do not support combustion because of their high chlorine content and will extinguish immediately upon flame removal

- Chlorinated PVC (CPVC) has added chlorine which makes it suitable for use at higher temps up to 100°C (210°F) and offers better corrosion resistance to liquids

- Used for hot process piping, corrosive liquids, hot and cold water lines, etc.

- Joining methods are solvent welding, threading, or flanging

Polyolefins (PP, CPP, PE) as Pipe Materials

Polypropylene (PP) is the lightest thermoplastic piping material. Good strength and chemical resistance, resistant to sulfur-bearing compounds. May be used up to 80°C (180°F) applications. Excellent material for industrial drainage, petroleum industry, salt water disposal, chilled water, and demineralized water lines.

Copolymer Polypropylene (CPP) is a copolymer of propylene and polybutylene. Has excellent dielectric and insulating properties, high chemical resistance, toughness, and strength between freezing to 93°C (200°F) operating temps. Excellent abrasion resistance and good elasticity. Joining by socket fusion or butt welding.

Non-metallic Polyethylene (PE) Piping Material has four classifications:

- Low-density polyethylene (LDPE) has more branching and less compact molecular structure, Lower mechanical strength than polyethylene; Ideal for food handling services, brine tanks, etc. Good for temps up to 60°C (140°F). Joining by hot gas welding. All polyethylenes have excellent chemical resistance to a wide range of common chemicals.

- Medium Density Polyethylene (MDPE) is a thermoplastic that has a lesser density than HDPE. It has good shock and drop resistance and better stress cracking resistance than HDPE. It has a lower hardness and rigidity when compared to HDPE. Used a lot in gas piping and fitting and in packaging films. Joining by hot gas welding.

- High-Density Polyethylene (HDPE) has minimal branching and a more compact molecular structure. More rigid and less permeable than LDPE. Good for temps up to 71°C (160°F). Used for abrasion-resistant piping, caustic storage tanks, control tubing, etc. Joining by hot gas welding.

- Cross-Linked High-Density Polyethylene (XLPE) is a 3-dimensional polymer of extremely high molecular weight and close molecular structure. Superior resistance to environmental stress cracking and very high impact strength. Good for temps up to 71°C (160°F). Ideal material for large storage tanks for outdoor service

Fluoroplastics (PVDF, HALAR, PTFE, FEP, PFA) Pipe Materials

Polyvinylidene Flouride (PVDF) is a strong, tough, abrasion-resistant fluoroplastic material. Resists distortion and retains strength up to 135°C (275°F). Ideal for handling wet and dry chlorine, bromine, and other halogen services. It also withstands most acids, bases, and organic solvents. PVDF is not recommended for strong caustics. The best material for high-purity piping such as deionized water. Joining methods are thermal butt, socket, or electrofusion.

Halar (ECTFE) Ethylene Chlorotrifluoro Ethylene is a very durable copolymer of ethylene and chlorotrifluoroethylene. Excellent resistance to a wide variety of strong acids, chlorine, solvents, and aqueous caustics. Excellent abrasion resistance, electric properties, low permeability, and temperature capabilities from cryogenic to 170°C (340°F). Resistant to radiation. Halar has an excellent application for high-purity hydrogen peroxide application. Joining by thermal butt fusion.

Polytetrafluoroethylene (PTFE) PTFE offers the most unique and useful characteristics of all plastic materials. PTFE can handle liquids or gases up to 232°C (450°F). PTFE flows and is used as an excellent sealant material. Normally an opaque white material.

Fluorinated Ethylene Propylene (FEP) This fluoroplastic was invented by DuPont. It can be melt-extruded and fabricated by conventional methods which allow more flexibility in manufacturing. Excellent dielectric and chemical resistance properties similar to PTFE. Use limited to temp between -54°C (-65°F) to a maximum of 150°C (300°F). It has a glossy surface and is transparent when in a thin section. FEP is widely used for its high ultraviolet light-transmitting ability.

Perfluoroalkoxy (PFA) is Similar to PTFE and FEP. Better properties than PTFE permits conventional thermoplastic molding and extrusion. Good flexibility for tubing purposes. Higher mech strength up to 260°C temperature.

Acrylonitrile Butadiene Styrene (ABS) is A family of engineered thermoplastics with a range of performance characteristics. Acrylonitrile imparts chemical resistance and rigidity to this thermoplastic. Butadiene endows it with impact strength and toughness. Styrene contributes to ease of processing. Good for hostile environments like esters, ketones, alcohols, and hydrocarbons up to 93°C (200°F).

Sulfone Polymers These are clear thermoplastics used in corrosive environments. Temp range up to 150°C (300°F). High resistance to acids, alkali, and salt solution. Not suited for ketones, chlorinated hydrocarbons, and aromatic hydrocarbons. Used a lot in flow meters and sight gauges

Forms of Sulfone Polymers

VITON – A fluoroelastomer compatible with many chemicals at varied temp ranges. Used for sealing valves, pumps, and instruments. Excellent for mineral acids, salt solutions, chlorinated hydrocarbons, and petroleum oils. The maximum temp limit is 120°C (250°F).

EPDM – Is a terpolymer elastomer made from the ethylene-propylene-diene monomer. Good abrasion and tear resistance. Excellent chemical resistance to a variety of weak acids and alkalies. Not recommended for applications involving petroleum oils, strong acids, or alkalies. The maximum temp limit is 100°C (212°F).

Nitrile BUNA-N- Nitrile rubber is a copolymer of butadiene and acrylonitrile. It has excellent elastomeric properties. It has excellent resistance to aliphatic hydrocarbons and aromatic solvents. Excellent material for valve seating. The maximum temp limit is 100°C (212°F).

HYPALON – This is a DuPont registered name for its elastomer of chlorosulfonated polyethylene. Used widely for valve seats and seals. The maximum temp limit is 100°C (212°F).

NEOPRENE – is a chlorinated synthetic rubber used primarily as a seating and sealing surface for valves. The maximum temp limit is 100°C (212°F).

NATURAL RUBBER – IS polymer isoprene with the highest molecular weight. Derived from Hevea (Rubber) tree. Used as the diaphragm and sealing material because of its elastomeric properties and resistance to abrasion. The maximum temperature limit is 100°C (212°F).

Thermoset Plastics as Piping Materials

Fiberglass Reinforced Plastic (FRP) is a highly valuable engineering material for piping and vessels (epoxy glass fiber). Very vast industrial use because of low initial cost & low maintenance. The broad range of chemical resistance. High strength-to-weight ratio. Ease of fabrication and flexibility in design. Good electrical insulation properties. It can be used up to a temperature of 150°C (300°F). Such epoxy piping is commonly used in oil, mining, and chemical industries. Sometimes used for steam condensate systems. Used in industrial cooling towers. Also used in Chlorine gas, chlorine water, and brine services.

Reinforced Thermosetting Resin Pipe (RTRP) Vinylester resin epoxy-based thermosetting resin material cured by free polymerization. Better tensile strength, elongation, and fatigue resistance. Material has excellent alkali resistance of the epoxy and acid and oxidation chemical resistance of the polymer. Used a lot in large bore seawater piping. Non-metallic piping material use is generally restricted to about 120°C (250°F). Check with vendors for specific applications for services and corrosion, sizes, fitting dimensions, jointing procedures, etc.

Typical Pipe Material Service checks

Caustic :

- Always check NaOH or KOH concentration before material selection

- Use Baume’s scale (Caustic Cracking Curve RP0403) for reference

- The typical material is CS and PWHT is required

- The typical valve trim is Monel

- If PWHT is not mandatory, do not allow steam out

Amine:

- Services include MEA (Mono Ethanolamine), DEA (Di Ethanolamine), DIPA (Di iso propanolamine), DGA (Di Glycolamine), etc.

- The typical material is CS and PWHT is required

- Fresh amines do not cause SCC; PWHT is not required, but if exposed to lean and rich amines, they require PWHT

- Restrict fluid velocity to < 2 m/sec for CS

- The preferred valve trim is SS 316

- Use SS for higher velocity and temps

Wet H2S:

- If H2S concentration in water is > wt% 50 to 75 ppm, it is susceptible to SCC

- PWHT required and material hardness to be restricted to 200 BHN

- NACE MR-0103 valves are not required but acceptable. Many use NACE valves as a norm

- CS with 300 series SS trim is typical for valves

- Always consult client/process for specific metallurgy requirements

Hydrogen (API 910/941):

- Hydrogen service is defined as a combination of H2 partial pressure and temp above the curve for CS per API 941

- Use Nelson’s Curve for material selection limits

- CS can be used up to 232°C

- 232° to 330°C use 1.25Cr or 2.25Cr/Mo steel or Duplex steel

- 330° to 400°C use SS 321

- 400°C use SS 347 or Alloy 800

- For higher pressure ratings (Class 600 & higher) valve casting inspection by radiography is a must and may need to go for non-standard valves – long lead item!!!

- Check for PWHT requirement for piping & NACE requirement for valve trim based on pp of Hydrogen and wet H2S concentration

Hydrofluoric Acid (HF) – Concentration > 1ppm:

- Very critical and hazardous service

- The typical material is CS

- PWHT is normally required, restrict hardness to 200 BHN

- Use special precaution during the purchase of piping components, shielding, and color coding

- Strictly follow piping specifications

Chlorine (Dry and Liquid):

- Follow Chlorine Institute guidelines for material selection and design. Leakage is hazardous

- Strictly follow pipe specification requirements

- Ball valves with soft seats are typically used

- CS is normally used in liquid chlorine services

- PWHT is normally not required

- Exercise high precaution in purchase spec for piping components w.r.t. cleanliness, packing, and shipping requirements

Ammonia (Aqueous and Gaseous application):

- In aqueous (Ammonia with water), CS is a commonly used material

- Strictly follow pipe specification requirements

- In gaseous service, low-temperature and cryogenic materials and codes shall be used

- Do not use CS if the temp is < -29°C

Oxygen (For concentration > 31%):

- CGA (Compressed Gas Association) standard shall be followed

- Strictly follow pipe specification requirements, special notes for design, and material selection

- Commonly used piping materials are CS, SS, and Monel

- Velocity in a pipe is a critical factor for material selection

- PTFE is the preferred material as gasket filler and for valve stem packing

- Avoid threaded piping

- Cleanliness requirement is very critical during material handling/shipping after fabrication

Common Metallic Piping Materials

The widely used Metallic Piping Materials are as follows:

- The most widely used seamless carbon steel pipe for high-temperature service up to 4270C is A106-B.

- The most widely used seamless low-temperature carbon steel pipe for a temperature up to -460C is A333-6.

- Common metallic pipeline materials for liquid and gas transport are API 5L, Gr B, X42, X52, and X60.

What’s up,I read your blog named “Piping Material and Metallurgy – Basic Guidelines for Selection: Part-1 of 3 – What is Piping regularly.Your writing style is awesome, keep doing what you’re doing!

Great guidance to piping material selection. Hearty thanks to the efforts which will help those in need.

GOOD SHARING OF THE KNOWLEGE.

VERY FEW PEOPLE TAKE THIS LEAD

WELL DONE

PROUD OF YOU

Thank you so much for this piece of information, Kindly keep on the good work,

Please, could you share how to prepare piping material list using PMC (piping material class).

Thanks once more.

Very useful knowledge based post for the people.

Keep it up and enlight the society is best thing anybody can do.

We learn a lot from your posts.

Informative article and it will be useful for young engineers. Thank you for sharing.

Thanks for sharing