What is a Buried Pipe/Pipeline?

Underground or buried piping (or Pipeline) is all piping that runs below grade. In every process industry, there will be some lines (Sewer or drainage system, Sanitary, and Storm Water lines, Firewater or drinking water lines, etc), part of which normally runs underground. However the term buried piping or underground piping, in a true sense, appears for the pipeline industry as miles of long pipe run carrying fluids will be there.

Analysis of Underground Piping System

Analyzing an underground pipeline is quite different from analyzing plant piping. Special problems are involved because of the unique characteristics of a pipeline, code requirements, and techniques required in the analysis. Elements of analysis include pipe movements, anchorage force, soil friction, lateral soil force, and soil pipe interaction.

Why Pipeline Stress Analysis is different from Piping Stress Analysis?

To appreciate pipe code requirements and visualize problems involved in pipeline stress analysis, it is necessary to first distinguish a pipeline from plant piping. Unique characteristics of a pipeline include:

High allowable stress of Pipeline

A pipeline has a rather simple shape. It is circular and very often runs several miles before making a turn. Therefore, the stresses calculated are all based on simple static equilibrium formulas which are very reliable. Since stresses produced are predictable, the allowable stress used is considerably higher than that used in plant piping.

High-yield strength pipe

To raise the allowable, the first obstacle is yield strength. Although a pipeline operating beyond yield strength may not create structural integrity problems, it may cause undesirable excessive deformation and the possibility of strain follow-up. Therefore, a high test line with a very high yield to the ultimate strength ratio is normally used in pipeline construction. The yield strength in some pipes can be as high as 80 percent of ultimate strength. All allowable stresses are based only on yield strength.

High-pressure elongation (Bourdon Effect):

The movement of the pipeline is normally due to the expansion of a very long line at the low-temperature difference. Pressure elongation, negligible in the plant piping, contributes much of the total movement and must be included in the analysis.

Soil-pipe interaction

The main portion of a pipeline is buried underground. Any pipe movement has to overcome soil force, which can be divided into two categories: Friction force created from sliding and pressure force resulting from pushing. The major task of pipeline analysis is to investigate soil-pipe interaction which has never been a subject in plant piping analysis.

Low Design Temperature

Normally these lines do not have high design temperatures (of the order of 60 to 82 degrees centigrade) and only thermal stress checking is sufficient for the underground part. Common materials used for underground piping are Carbon Steel, Ductile iron, cast iron, Stainless Steel, and FRP/GRP.

In this article, I will try to explain the steps followed while analyzing such systems using Caesar II. However, this article does not cover the basic theory for analysis.

Inputs Required for U/G Pipe Stress Analysis

Before proceeding with the analysis of buried piping using Caesar II collect the following information from the related department

- Isometric drawings or GA drawings of the pipeline from the Piping layout Department.

- Line parameters (Temperature, Pressure, Material, Fluid Density, etc) from the Process Department.

- Soil Properties from the Civil Department.

Caesar II for Underground Piping Analysis

The CAESAR II underground pipe modeler is designed to simplify user input of buried pipe data. To achieve this objective the “Modeler” performs the following functions for analysts:

Allows the direct input of soil properties. The “Modeler” contains the equations for buried pipe stiffnesses that are outlined later in this report. These equations are used to calculate first the stiffnesses on a per length of pipe basis, and then generate the restraints that simulate the discrete buried pipe restraint.

Breaks down straight and curved lengths of pipe to locate soil restraints. CAESAR II uses a zone concept to break down straight and curved sections. Where transverse bearing is a concern (near bends, tees, and entry/exit points), soil restraints are located in close proximity, and where axial load dominates, soil restraints are spaced far apart.

Allows the direct input of user-defined soil stiffnesses on a per-length-of-pipe basis. Input parameters include axial, transverse, upward, and downward stiffnesses, as well as ultimate loads. Users can specify user-defined stiffnesses separately, or in conjunction with CAESAR II’s automatically generated soil stiffnesses.

Modeling steps followed in Caesar II

The modeling of buried piping is very easy if you have all the data at your hand. The following steps are followed for modeling:

From the isometric model, the line is in the same way as you follow in the case of an above-ground pipe model i.e, enter line properties in Caesar Spreadsheet, enter lengths by breaking the line into several nodes, or select an existing job for converting it into an underground model.

The analyst can start the Buried Pipe Modeler by selecting an existing job and then choosing Input-Underground from the CAESAR II Main Menu. The Modeler is designed to read a standard CAESAR II input data file that describes the basic layout of the piping system as if it was not buried. From this basic input, CAESAR II creates a second input data file that contains the buried pipe model. This second input file typically contains a much larger number of elements and restraints than the first job. The first job that serves as the “pattern” is termed the original job. The second file that contains the element mesh refinement and the buried pipe restraints is termed the buried job. CAESAR II names the buried job by appending a “B” to the name of the original job.

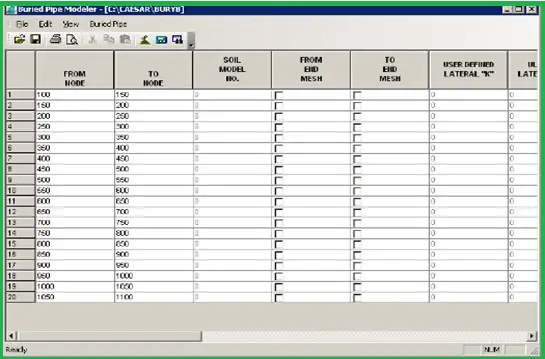

When the Buried Pipe Modeler is initially started up, the following screen appears:

This spreadsheet is used to enter the buried element descriptions for the job. The buried element description spreadsheet serves several functions:

- It allows the analyst to define which part of the piping system is buried.

- Allows the analyst to define mesh spacing at specific element ends.

- Allows the input of user-defined soil stiffnesses.

From/ To node

Any element of pipe in CAESAR II can be defined by two elements first is a start point and the second is an endpoint. In the buried pipe model, before conversion, the From/ To nodes remain the same as in the unburied model.

Soil model No

This column is used to define which of the elements in the model are buried. A nonzero entry in this column implies that the associated element is buried. A 1 in this column implies that the analyst wishes to enter user-defined stiffnesses, on a per-length-of-pipe basis, at this point in the model. These stiffnesses must follow in columns numbers 6 through 13. Any number greater than 1 in the soil model no. column points to a CAESAR II soil restraint model generated using the equations outlined later under Soil Models from analyst-entered soil data.

From/ To mesh type

A critical part of the modeling of an underground piping system is the proper definition of Zone 1 bearing regions. These regions primarily occur:

- On either side of a change in direction

- For all pipes framing into an intersection

- At points where the pipe enters or leaves the soil

- CAESAR II automatically puts a Zone 1 mesh gradient at each side of the pipe framing into an elbow. Note it is the analyst’s responsibility to tell CAESAR II where the other Zone 1 areas are located in the piping system.

User-defined stiffness & ultimate load

There are 13 columns in the spreadsheet. Columns 6 to 13 carry the user-defined soil stiffnesses and ultimate loads if the analyst defines soil model 1. The analyst has to enter lateral, axial, upward, and downward stiffnesses & loads.

Procedure

Select the original job and enter the buried pipe modeler. The original job must already exist and will serve as the basis for the new buried pipe model. The original model should only contain the basic geometry of the piping system to be buried. The modeler will remove any existing restraints (in the buried portion). Add any underground restraints to the buried model. Rename the buried job if the CAESAR II default name is not appropriate.

Enter the soil data using Soil Models.

Describe the sections of the piping system that are buried, and define any required fine mesh areas using the buried element data spreadsheet.

Convert the original model into the buried model by the activation of option Convert Input. This step produces a detailed description of the conversion.

Exit the Buried Pipe Modeler and return to the CAESAR II Main Menu. From here the analyst may perform the analysis of the buried pipe job.

The steps to create a soil model and other important considerations are covered in the following article: Underground Piping Stress Analysis Procedure using Caesar II. Click here to read that article.

Online Video Course on Buried/Underground Piping/Pipeline System Stress Analysis

If you need to join an online buried pipe stress analysis course using Caesar II to learn the above using a practical case study then click here to join the same.

Few more Resources for You..

Video Tutorial of Buried Piping Stress Analysis using Start-Prof

Basics for Stress Analysis of Underground Piping using Caesar II

What if Piping Continuation is Unknown? Part 2. Underground Piping

A short presentation on Various Analysis methods for Underground Piping Using Caesar II

Piping Stress Analysis Basics

Piping Design and Layout Basics

I read a lot of interesting articles here. Probably you spend a lot of time writing,

The articles posted here are of good knowledge and helps readers to understand the concepts of piping and its engineering.

Thanks for publishing this important article. I have a question.

Sometimes we only have alignment sheets as the underground pipeline drawings. Can we prepare piping model with only alignment sheets?

I hope your piping model will have a portion where undergorund pipeline will come out above the ground using a bend or S-bend. I am eagerly waiting to know how to handle this portion.

Dear Riton Nuruzzaman,

Surely, alignment sheets can be used for modeling, as all required data is available in these sheets.

Pipeline stress analysis I doing, buried model I completed. One problem will be there for buried model before of the two support is lifted. So how to solving this porsion.

I think buried pipelines are much more easy to model using PASS.Start-Prof software, not Caesar

passuite.com