What is PMP Certification?

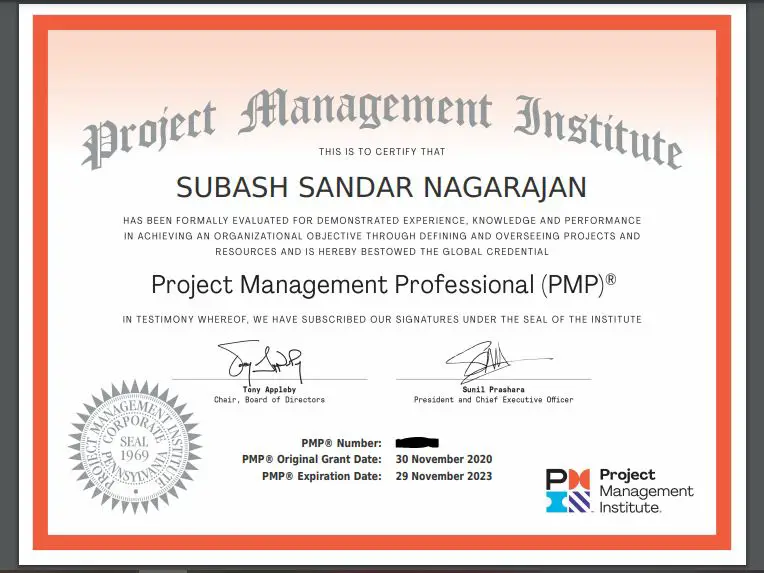

PMP® Certification is a Project Management Professional Certification issued by Project Management Institute. There is no doubt that PMP is one of the most valued Certifications in the entire world of Project Management. PMP-certified managers have a certain level of prestige and greater access to jobs with higher salaries. Research conducted on several firms has discovered that companies with PMP-certified project managers are more competitive, productive, and meet their goals within the scheduled time. Several salary survey reveals that “PMP certification holders draw 20-25 percent more salary than their non-certified counterparts”

How do I get inspired for PMP Certification?

When I decided to improve my skills I searched on the Internet and LinkedIn to get the relevant course. After weeks of searching, I came to know about PMP certification. Then I started a deep search about the Project Management and Project Manager’s increments in roles, Salaries, and the respect they get after having the 3 Letters (PMP) behind their names.

I was surprised to know that only 1 Million active PMP Certified Professionals are available in the entire world over the span of 4 decades. I was super shocked to know that only 40,000 and 150,000 active PMPs in India and China respectively. The ratio is 0.006 % which is an almost negligible number (190,000/2.8 Billion). For your Understanding – If you go for an Interview that has 100,000 Competitors from India and China, there is a possibility of having 7 PMPs appearing for the interview. Sounds Great… Right! This is the real scenario by the way. Continue reading this article in which I will share my success story in achieving the PMP global credentials. It looks like so many activities but it is simple indeed.

See the below Image (Fig. 1), It was the daily update of the newsfeed on my LinkedIn from September to December 2020. Several Engineers, Managers utilized the COVID-19 situation to prepare for the PMP Exam and successfully clear it.

I was inspired and motivated by the success of others and also I don’t want to be the guy who is standing in the middle of the below Image. I believe you will not be the one after reading this article. I’m not going to say the same as what all the articles about the PMP explain.

Stepwise action plan for PMP Certification

Below are the step-by-step actions you have to plan and follow to fulfilling your dream to be PMP certified.

- Believe in yourself that you will be PMP after passing the Exam. Explain this to your family members as well. Without their support, it is almost impossible to spend time on preparation. Dedication is the most important investment for this exam.

- When you start preparing turn off your expert mode and change to learner mode. In other words, you should not compare what you learn with what you have experienced before. The examination will be from the PMI Point of View only. You should unlearn your experience to understand the concept as per the PMBOK (Project Management Body Of Knowledge) guide.

- Make a plan for gaining 35 hours of Education (A mandatory Requirement for the PMP Exam) from PMI-approved trainers. [I took UDEMY COURSE BY JOSEPH PHILLIPS – Less than 10$ on offer- Highly Recommended] (You can Check the PMI Website to Learn about PMP Exam Requirements). There are many other courses on Udemy which can be accessed by clicking here.

- Find a mentor who is ready to understand and support you by providing mock test questions, explanations, and doubt-clearing sessions. I was lucky to have a mentor with 100 % dedication. He played a major role in my success.

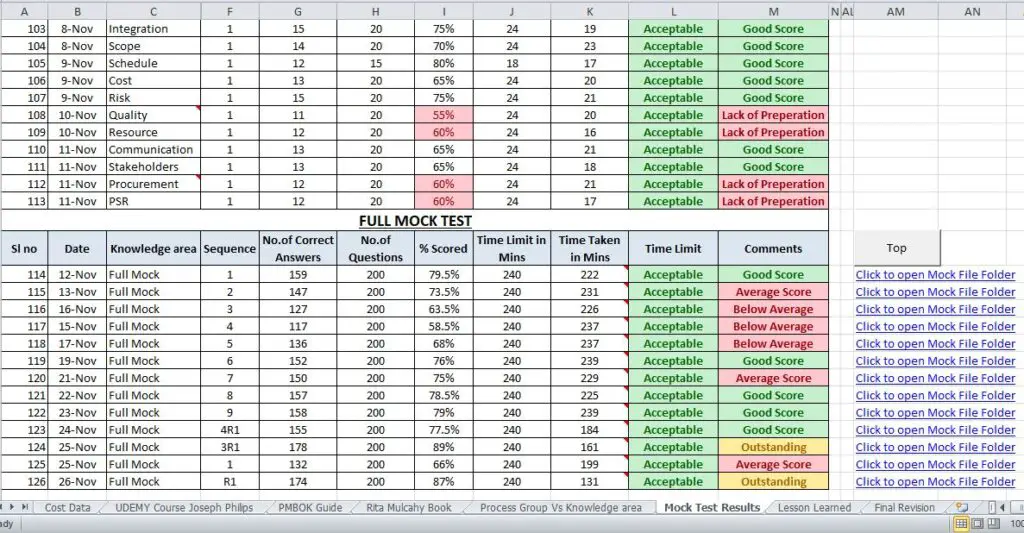

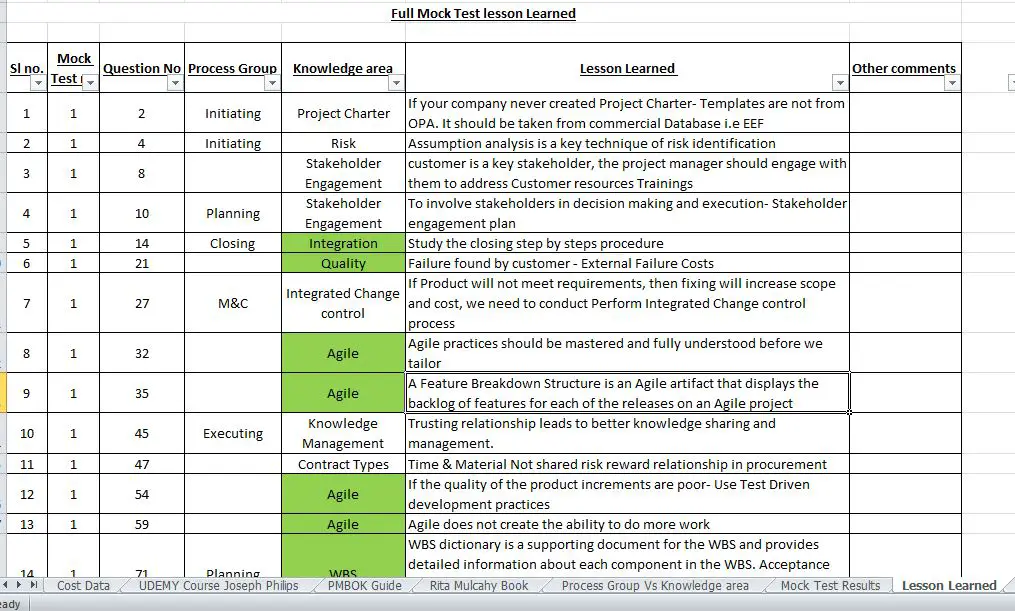

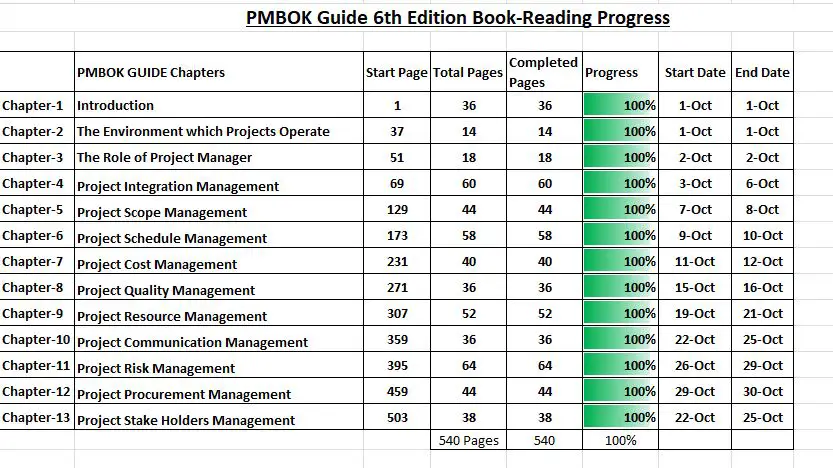

- Prepare an MS Excel Spreadsheet consisting of below

- Study plan with Start and Finish Dates

- Mock Test score

- Weak Knowledge Area

- Expenses for the Course including exam Fees.

- Purchase PMBOK Guide Hard Copy to study comfortably. Many persons suggested using Rita Mulcahy’s book as a guide for people having difficulty in reading PMBOK. Don’t go for more than 2 books to avoid misunderstanding.

- Check Youtube Videos from PMPwithRay which are very useful for understanding ITTOs (Inputs, Tools & Techniques, Outputs of Processes on all the 10 Knowledge areas). No need to memorize ITTOs, very few or no questions will directly ask about the ITTO’s.

- Try purchasing the membership together with the exam schedule. I suggest following to book the exam date as per the below steps.

- Gain 35 Hours of Education

- Submit the Exam application (Will be approved within 5 working days)

- Attend at least 8-10 Full Mock tests (Free Mocks Available Online)

- Analyze the results of the mock tests by categorizing the wrong answers by knowledge area. Carry out the 80/20 Pareto principle (i.e) 80% of your mistake will come from 20% of the knowledge area. If you are able to learn those topics with mock scores of about 75-80 % you are on the safer side.

- Once you gain confidence after attending the mocks, pay for the 1-year membership on PMI Website together with the exam fee (You will get a discount if you have a membership)

- You can fix the exam date and you can write the exam Online from home or through the Pearson Vue Test Center.

- Experience on Exam Day:

- The PMP exam is really a difficult exam I ever attended. The exam will have 2 sessions with a break in between.

- PMP certification is designed by project professionals, for project professionals and validates that you are among the best—highly skilled in three major topics PEOPLE, PROCESS, and BUSINESS ENVIRONMENT. So, You cannot ignore some topics during preparation. To Pass the Exam You have to score more than Target on all three Topics.

- You have to be clear on 3 approaches AGILE, WATERFALL & HYBRID. It is to validate that you have the project leadership skills employers seek. So, you will prove yourself.

- The most common problem during the exam is there will be 2-3 choices that look like the right answer in the multiple-choice questions. The only solution is to have a lot of practice. (I answered 5800 Questions during preparation through mock tests)

- The next common problem during the exam is time management. I have heard many people told that they cannot answer all the questions so they failed the exam. I have a very good solution for this. From the beginning of mock tests consider 1 minute for 1 question, so you will finish the exam in 3 hrs’ time. Use the remaining time to review the answers. Hope this will help.

- If you feel you are not sure, mark the question for review and check later. Don’t read the question more than 2 times in the final exam.

That’s it!! It May look difficult but not impossible, you are reading this so you have the hunger to earn PMP certification. You are doing the right thing which many are not even thinking about.

I’m glad to share screenshots of the excel file and PMP Certificate for motivating the PMP Aspirants.

My LinkedIn Profile views were at their peak when I posted that I have passed PMP Exam. I thanked all my family members, my Mentor, and all the people who supported and guided me to get these global credentials.

Finally, I would like to share the words of Mr. Joseph Phillips ” KEEP MOVING FORWARD”, “I BELIEVE YOU CAN DO THIS”.

Please post when you pass the exam after checking these articles.

I want to share a copy of the MS Excel file I prepared for my self-assessment. Who want to have the Full PDF file or Draft of the Original XLS Format, drop me an Email: subashmech2011@gmail.com.

Frequently asked questions about PMP Certification

1. Is PMP better than MBA?

Undoubtedly yes! Because MBA is mostly study-oriented whereas PMP is mostly experience-oriented. That’s why PMP Aspirants should have a minimum of 3 years of Work Experience.

2. If an engineer is not working in the project department, can he attain PMP certification?

Yes. Any Engineering Graduate with 3 years of Experience is eligible to get the PMP Global credentials. Whether you are from IT or from Non-IT (like Construction, Finance, Banking, FMCG, Engineering, or Real Estate) PMP knowledge can be applied. Whenever there are new projects then Project Management will come into play. So earning a PMP is always an added advantage and will enhance your skills.

3. I’m not an engineer, I want to earn PMP. Can I go for it?

Of course Yes. You can go for it. Qualification is to have a high school diploma or an associate’s degree (or global equivalent) with 5 Years of Experience or get a CAPM certification from PMI.

4. I saw advertising from some learning centers that mentioned “You get the PMP Certification within a week”. “You earn PMP without appearing for the exam” Is it possible?

These are the keywords used by frauds, and spammers who are looking for cheating people who want to cheat in the exam. If you come across this kind of advertisement, please don’t believe them, you will lose your money and hope to pass the exam. No Pain, No gain!