Welding is a critical process in manufacturing and construction, but it can also introduce stresses and imperfections in the welded joints. To mitigate these issues, post-weld heat treatment (PWHT) is employed to enhance the integrity and performance of welded components. This article provides a comprehensive overview of PWHT, including its principles, methods, applications, and benefits.

What is PWHT or Post Weld Heat Treatment?

The full form of PWHT is post-weld heat treatment. PWHT is a controlled process that involves reheating the metal below its lower critical transformation temperature, following a welding process. The material is then held at the elevated temperature for a predetermined period of time to alleviate residual stresses, increase the strength, increase or decrease the hardness, and reduce the risk of cracking by microstructural changes. An array of heating processes can be used to carry out post-weld heat treatment. The primary objectives of PWHT include:

- Reducing Brittle Phase Formation: In some materials, PWHT helps to minimize the formation of brittle phases that can lead to premature failure.

- Relieving Residual Stresses: Welding generates thermal gradients that can create internal stresses. PWHT helps to redistribute these stresses.

- Enhancing Mechanical Properties: Heat treatment can improve ductility, toughness, and hardness in the heat-affected zone (HAZ) and base material.

The Need for PWHT

The necessity for Post Weld Heat Treatment (PWHT) primarily arises from the residual stresses and microstructural changes that occur after welding. During the welding process, a significant temperature gradient develops between the weld metal and the parent material. As the weld cools, it generates residual stresses, which can become unacceptable, particularly in thicker materials, potentially exceeding design limits. To mitigate these stresses, the part is heated to a specified temperature for a designated period, allowing the stresses to be reduced to acceptable levels.

In addition to residual stresses, the high temperatures associated with welding can alter the material’s microstructure, often increasing hardness while diminishing toughness and ductility. PWHT effectively addresses these changes, helping to lower hardness levels and restore toughness and ductility to meet design specifications.

The necessity of PWHT largely depends on the materials being welded, the service conditions, and the specific application. For instance, high-strength steels, low-alloy steels, and certain alloys are more susceptible to issues that PWHT can address. Industries like oil and gas, nuclear, and power generation often mandate PWHT to ensure structural integrity.

When is PWHT required for Carbon Steel?

Post Weld Heat Treatment or PWHT, of Carbon Steel must be performed after every welding in order to ensure the material strength of the part is retained. The exact criteria for PWHT of carbon steel are mentioned in the ASME BPVC code. PWHT ensures the reduction of residual stresses, controlling material hardness, and enhancement of mechanical strength.

Advantages of Post Weld Heat Treatment

If PWHT is neglected or performed incorrectly, the residual stresses can combine with service load stresses. The value may exceed a material’s design limitations, leading to weld failures, higher cracking potential, and increased susceptibility to brittle fracture. PWHT significantly enhances the quality of welds, leading to fewer failures and increased longevity of structures.

Other benefits of PWHT are listed below:

- Improved metallurgical structure

- Improved ductility of the material

- Reduced risk of brittle fracture as ductility increases

- Relaxed thermal stress due to the redistribution of residual stresses.

- Tempered metal

- Reduced chance of cracking

- Reduced hardness

- Removal of diffusible hydrogen, which helps in preventing Hydrogen-Induced Cracking (HIC)

- Increased stability of the weld in further mechanical works

- Improved corrosion resistance.

- Many industries have strict codes and standards that require PWHT, making it essential for compliance.

Principles of Post-Weld Heat Treatment

Basic Concepts

PWHT involves heating the welded assembly to a specified temperature for a defined duration, followed by controlled cooling. The key principles include:

- Temperature Control: The temperature is critical; it should be high enough to achieve the desired material properties but low enough to avoid adverse effects such as excessive grain growth.

- Soaking Time: The duration at which the material is held at the target temperature is equally important. This ensures uniform temperature distribution and effective stress relief.

- Cooling Rate: Controlled cooling is essential to prevent the formation of new stresses. Rapid cooling can lead to hardening and cracking.

Metallurgical Considerations

The metallurgical characteristics of materials are significantly affected by the heat treatment process:

- Phase Transformations: Heating can induce phase changes in materials, which can enhance their mechanical properties.

- Grain Refinement: Proper heat treatment can lead to finer grain structures, resulting in improved strength and toughness.

- Stress Relief: PWHT promotes dislocation movement within the crystal structure, helping to relieve residual stresses.

Post Weld Heat Treatment Method and Equipment

- The local post-weld heat treatment of the welded joints on the pipes shall be carried out by the electric-resistance method after the completion of all welding or repair operations.

- The resistance heater is electrically and thermally self-insulated and is built to size for each individual pipe.

- The applied voltages across the coils are either 220 or 380 volts AC, depending on the power requirements.

The power-control panel of post-weld heat treatment is composed of:

- A temperature controller indicator and recorder of digital type.

- A potentiometer device that controls the percentage of power input to the coils.

- A switch On and Off indicator lights, input, and output terminals for power and thermocouple connection.

- Electrical power contactors of the proper rating.

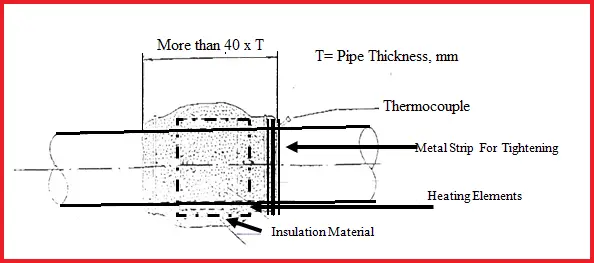

Each panel will supply a single heating station and therefore for each heating operation, one panel will be needed. Heating and cooling rates are adjusted by manual selection of the percentage of power input by means of potentiometers. Fig. 1 below shows an example of PWHT in the piping applications.

Requirements for Post Weld Heat Treatment or PWHT

Before applying for the detailed PWHT requirements and exemption in these paragraphs, satisfactory weld procedure qualifications of the welding procedures specification to be used shall be performed in accordance with all the essential variables of ASME SECTION IX including conditions of post-weld heat treatment and other restrictions listed below.

While carrying out local post-weld heat treatment, the technique of application of heat must ensure uniform temperature attainment at all points of the portion being heat treated. Care shall be taken to ensure that the width of the heated band on either side of the weld edge shall not be less than four (4) times pipe thickness or 2″, whichever is greater.

Throughout the cycle of post-weld heat treatment, the portion outside the heated band shall be suitably wrapped under insulation so as to avoid any harmful temperature gradient at the exposed surface of the pipe. For this purpose, the temperature at the exposed surface of the pipe should not be allowed to exceed 400 °c.

The valves, instruments, and other special items with welding ends shall be protected because of the risk of damage during post-weld heat treatment.

No welding shall be performed after PWHT.

Automatic temperature recorders that have been suitably calibrated shall be employed. The calibration chart of each recorder shall be submitted to the owner prior to starting the heat treatment operations and his approval shall be obtained. Recording equipment shall be calibrated at least once every 12 months. Also, the instrument equipment (potentiometer) which is used for the calibration of recorders should be supported by a related certificate.

Preparation and Attachment of Thermocouple for PWHT

After performing a visual inspection and removing surface defects and temporary tack welds (if any) an adequate number of thermocouples (based on the diameter of pipes) shall be attached to the pipe directly and in an equally spaced location along the periphery of the pipe joint. The minimum number of thermocouples attached per joint shall be

- 1 for up to 3″ diameter,

- 2 for up to 6″ diameter,

- 3 for up to 10″, and

- 4 for up to 12″ diameter and above.

However, the required minimum number of thermocouples to be attached can be increased if it is found necessary.

The thermocouples shall be placed on the joint and in firm contact with the pipe as near as possible to the weld area. Thermocouples should be directly tack welded to the joint or heating band jointly provided that they have a tail of the same material and approved filler wire or electrode not larger than 2.5 mm in diameter is used for tack welding.

In order to avoid incorrect temperature readings due to direct radiation to thermocouples, it shall be protected by ceramic fiber blanked or any other suitable insulation material.

Heating resistance elements shall be laid over the attached thermocouples throughout the heating band and shall be insulated as shown in Fig. 2 below.

Insulating materials shall be mineral wool/glass wool, which can overcome the temperature employed. The minimum insulation thickness shall be 50 mm. To hold the insulation material in position, wire mesh shall be wrapped around and tied or tied by other suitable means.

PWHT Temperature, Time Record

The post-weld heat treatment temperature and time and its heating and cooling rates shall be recorded automatically and present the actual temperature of the weld area. Each thermocouple shall be connected to the controlling and recording instrument for each treated joint.

Heating, Holding, and Cooling in PWHT

The heating temperature above 300°c shall be recorded and the heating and cooling rate shall not be more than that specified in related WPS and standards but in no case, more than 200°c/hr and the difference between the temperatures measured by various thermocouples shall be within the range specified.

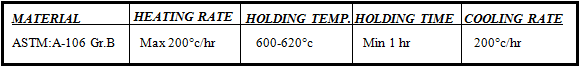

The heat treatment soaking temperature and holding time shall be as specified in related welding procedure specifications. For easy reference, the values for different types of steel are given in the following table.

The cooling down to 300°c shall be controlled cooling. Below that, the cooling down to ambient temperature shall take place under insulation coating without control.

The post-weld heat treatment temperature for ASTM A672, ASTM A234, ASTM A671, and ASTM A420 is generally 635 (+/-15) Degrees Centigrade.

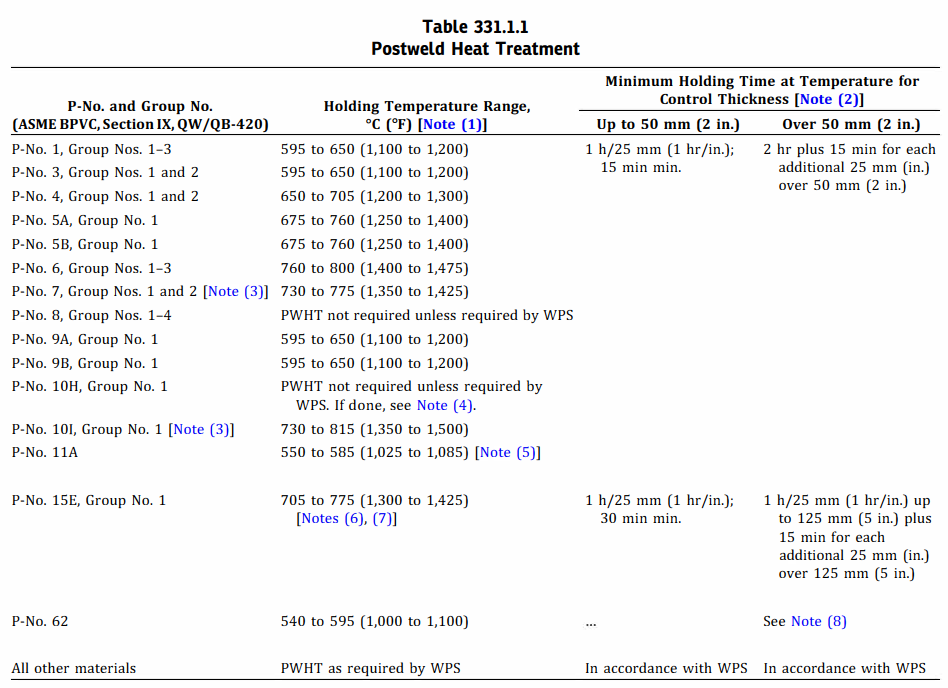

Post-Weld Heat Treatment Temperature as per ASME B31.3

ASME B31.3 specifies the PWHT temperatures with respect to the P Number of the material. Table 331.1.1 provides the PWHT holding temperature range. The same is reproduced below (Fig. 3) for your reference.

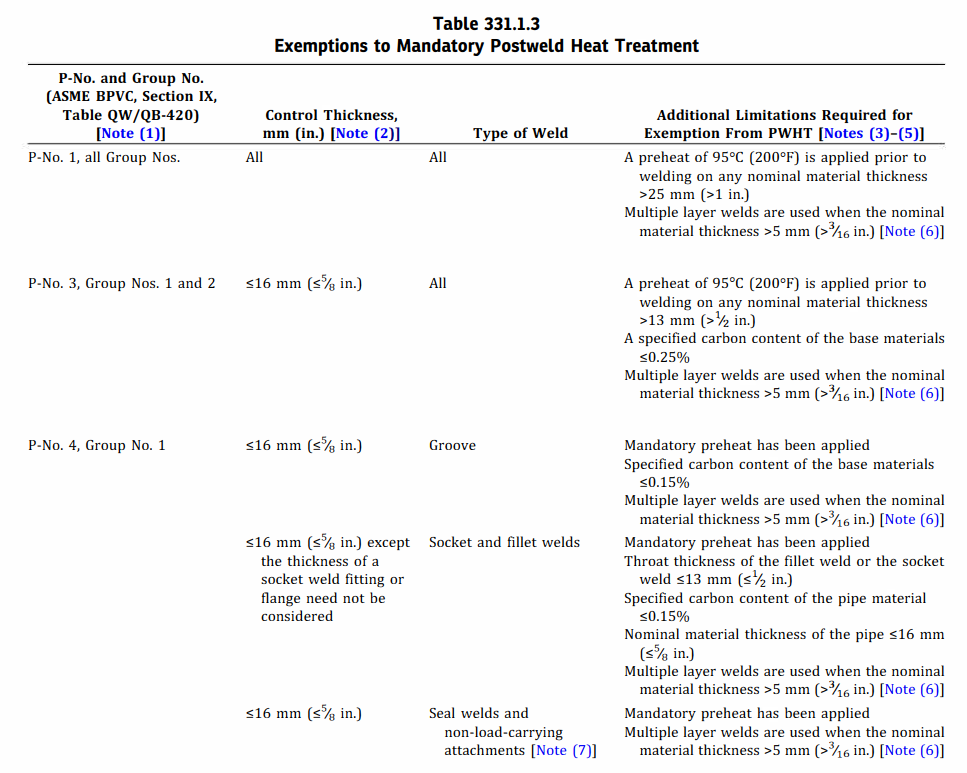

Additionally, table 331.1.3 provides certain exemptions from mandatory heat treatment. So, both Tables must be referred to concurrently.

Types of Post-Weld Heat Treatment

The PWHT process can be classified into two groups:

- Full PWHT, where the entire sample is subjected to heat treatment in a furnace, and

- Local PWHT, where localized heating is performed near the welding area only

Post Weld Heat Treatment Techniques

Industrial post-weld heat treatment is carried out using different techniques, as listed below:

Conductive (electrical resistance) Method of Post Weld Heat Treatment:

The conductive method of PWWHT uses ceramic fiber, band, snake, and other resistors based on the object dimension, together with precision control, programming, and automatic recording equipment. This method of heat treatment using electrical resistance is a common method for local PWHT in the field.

Inductive Post Weld Heat Treatment Method:

In this method, Currents induced by high-frequency coils generate the required heat. The generated heat increases the metal temperature as per the PWHT requirement. The number of coils and length of cable needed to achieve the objective is pre-determined.

Convective PWHT Method:

This method is also known as internal combustion treatment. In the convective post-weld heat treatment technique, the heat generated with the help of gas/diesel burners is transferred to the weld by the convection process. This method is widely used for large objects like pieces of equipment requiring very high power levels. This type of post-weld heat treatment is also recommended for pipe prefabrication works where the processing volume is very high.

Some Important Notes related to PWHT

- PWHT operation shall be performed only by trained personnel having a similar experience and approved by the owner.

- During PWHT joints shall be protected from rain and wind by adequate rain cover and windshield.

- Hardness tests after PWHT shall be performed to determine if heat treatment has been performed effectively. Normally for Carbon Steel, the maximum Brinell Hardness is 200 HB.

Safety Precautions during PWHT

The following safety precautions shall be provided during PWHT:

- Equipment and panels shall be properly earthed.

- Electrical technicians shall work with proper safety wear such as rubber gloves, shoes, etc.

- Only certified electricians will work.

- Joints under PWHT shall be well cordoned with red tape/red light and danger display to avoid unknown persons coming in contact with high voltage electrical connections.

- An adequate platform shall be made for in situ joints to avoid the fall of a person.

Stainless Steel PWHT

PWHT for stainless steel is usually not required. However, to increase the corrosion resistance or reduce stress corrosion cracking susceptibility, stainless steel PWHT may be used depending on the service conditions encountered.

PWHT for Piping

The requirements for PWHT for piping are dependent on the P-numbers and Group numbers of the pipe material. Clause 331.1.1, along with Table 331.1.1 and Table 331.1.2 of ASME B31.3, provides the requirements for PWHT depending on pipe materials. However, if the proper pre-heat temperature is applied during the welding of pipes of specified thicknesses, the mandatory post-weld heat treatment can be exempted. Such rules are provided in Table 331.1.3 of ASME B31.3.

Applications of Post-Weld Heat Treatment

PWHT is used across various industries, each with specific requirements and standards. Here are some prominent applications:

Oil and Gas Industry

In the oil and gas sector, pipelines and pressure vessels are subjected to extreme conditions. PWHT ensures that welded joints can withstand high pressures and corrosive environments. Specific standards, such as ASME Section VIII, often mandate PWHT for certain materials.

Nuclear Industry

Nuclear power plants require the highest standards of safety and reliability. PWHT is critical for ensuring the integrity of welded joints in reactor vessels and piping systems. Compliance with stringent regulatory standards is essential.

Power Generation

For power plants, particularly those using fossil fuels or nuclear energy, PWHT is vital for components such as boiler tubes and heat exchangers. It helps to improve resistance to thermal fatigue and enhances overall reliability.

Structural Fabrication

In structural engineering, PWHT is used in the fabrication of steel structures, especially in high-rise buildings and bridges. It ensures that the material properties meet design specifications and safety standards.

Disadvantages of PWHT

Post Weld Heat Treatment (PWHT) offers many benefits, but it also comes with several disadvantages. Here are some common drawbacks:

- Cost: PWHT can be expensive due to the need for specialized equipment, facilities, and skilled labor, which can increase project costs significantly.

- Time-Consuming: The heat treatment process can be lengthy, potentially delaying project timelines. Both heating and cooling cycles require careful control and monitoring.

- Equipment Limitations: The need for large furnaces or other heating equipment can pose logistical challenges, especially for large components that may not fit easily.

- Potential for Distortion: Improper heat treatment can lead to warping or distortion of the welded component, necessitating additional corrective measures.

- Material Limitations: Not all materials respond positively to PWHT. Some alloys may become brittle or lose desirable properties if subjected to heat treatment.

- Quality Control Challenges: Ensuring uniform temperature distribution and proper monitoring throughout the process can be challenging. Inadequate control may lead to suboptimal results.

- Skill Requirement: PWHT requires skilled personnel to manage the process effectively, and finding qualified workers can be difficult.

- Post-Treatment Inspection: Additional inspections are often necessary after PWHT to ensure that the desired mechanical properties have been achieved, further adding to project timelines and costs.

- Thermal Fatigue: Repeated heating and cooling cycles can lead to thermal fatigue in some materials, potentially reducing their overall lifespan.

- Compliance and Documentation: Meeting industry standards and maintaining thorough documentation can be cumbersome, especially in regulated industries.

Frequently asked questions related to PWHT

In the following section, I will address some of the most frequently asked questions related to PWHT.

What is the full form of PWHT?

PWHT is an acronym for the full form of Post Weld Heat Treatment.

When is PWHT required?

Most of the conventional welding processes generate residual stresses in the welding regions. These stresses in certain conditions can approach the yield strength of the material. Such joints are prone to failure and can not be used directly. PWHT is applied to such welded steel assemblies to reduce the likelihood of brittle failure. PWHT significantly reduces the residual stresses in the weld joints and thereby reduces the failure potential. So, wherever there is a risk of environmentally assisted cracking, PWHT is required.

What are the ASME B31.3 PWHT requirements?

The ASME B31.3 PWHT requirements for piping materials are established in clause 331.1.1 along with Table 331.1.1, 331.1.2, and 331.1.3.

How to calculate PWHT temperature?

PWHT temperature is not calculated. The range of PWHT temperatures is mentioned in tabular formats in the governing codes. So, the PWHT temperature is selected from the tables of the governing code. For example, table 331.1.1 of ASME B31.3 for process piping systems.

What is the difference between Post Weld Heat Treatment and Stress Relieving?

Stress-relieving is a process to reduce residual stresses in an object. Heat treatments like normalizing, annealing, quenching, tempering, etc are some of the processes to relieve the residual stresses generated by welding. PWHT is also a process in which stress relief is achieved. However, the main difference between Stress relieving and PWHT is that the stress-relieving can be made at temperatures below the minimum transformation temperature of the steel where no micro-structural change of the material occurs.

Some more Useful Resources for you.

General requirements for Field Welding

Underwater Welding & Inspection: A short Presentation

13 major differences between Seamless and Welded Pipe

Procedure for Post Weld Heat Treatment (PWHT) in Carbon Steel and Low Alloy Steel Materials

Hi Anup, the article is well explained but one thing is missing which I believe is

“Criteria where PWHT is applicable material/ thickness wise as per ASME31.3” needs to be mentioned like CS pipe with thickness above 20mm etc..

Our Isos usually specifies which line to have PWHT. Appreciate if you cover this vital info.

Best regards

Nikhil Nanivdekar

Mob:- 7718831017

What are the detrimental effects of exceeding the specified heating and cooling rates within the restricted cooling and heating temperatures?

How many weld joints can be tested with 1 power controlling panel ?

What is the maximum time (hours / days) that the PWHT shall be conducted after welding activity ?

Hi, Can some one help in understanding the minimum and maximum dwell period required to perform PWHT on a piping joint.

Aliter:

What is the minimum and maximum time after welding of a joint, PWHT can be performed.

whether in offshore structures, I can weld TKY Joints, after stress relieving of parent material.

learn more information in this article

PWHT ka code kya hoga

Essential variables of PWHT?

Hi everybody! I am Welding Inspector

also interesting PWHT

How about to color used in chart, Is it essential based on the code or depends on internal procedure?

good afternoon sir i am intrest the PWHT teqnicuhe and why do procedure ,processes if can be required are pwht