What is a Spectacle blind and Spacer?

Spectacle blinds and Spacers are pressure-retaining devices used in the piping/pipeline industry to temporarily or permanently blind (shut) or isolate part of the piping or pipeline system.

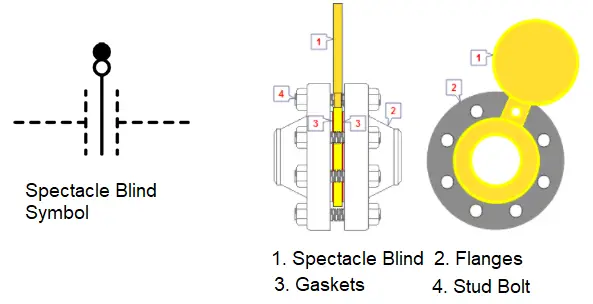

- A spectacle blind is a forged product and a combination of a flange spade and a ring spacer in one single product.

- One end of the spectacle blind will have an opening that allows fluid flow through the pipe during operation and the other end is made solid to block flow during isolation or maintenance time.

- One can simply rotate the spectacle blind by 180 degrees to close or open the fluid flow through the piping system.

- However, when there is space constraint, Flange spades and ring spacers can be used as separate products.

- As one of the two discs is always outside the pipe, one can easily understand if the blind is in an open or closed position.

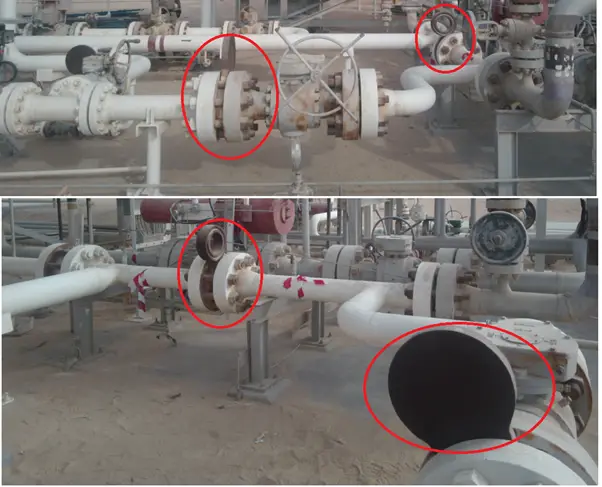

As it looks like the numeric number Eight or a pair of eyeglasses, a Spectacle blind (Fig. 1 & 2) is also known as a figure 8 blind or figure 8 spectacle blind.

Design Code and Standards for Spectacle Blind

ASME B16.48 is the governing code for spectacle blind design. This specification provides the dimensions, pressure-temperature ratings, materials, marking, dimensional tolerances, and testing requirements of the Spectacle blind. In general, Blinds are available in sizes NPS 1/2 – NPS 24, and these are installed between ASME B16.5 piping flanges in the 150, 300, 600, 900, 1500, and 2500 Pressure Classes. They are manufactured from steel plates and are available in forged material grades like ASTM A105 (high-temperature carbon), A350 (low-temperature carbon), and ASTM A182 grades (alloy, stainless steel, duplex).

Bigger size spectacle blinds with a diameter of>24 NPS are also available, but these are custom-made. Spectacle blinds of Carbon steel Material are normally manufactured from a single piece of steel, whereas alloy / stainless steel blinds can be produced by welding more pieces together.

Various spectacle blind standards used in industrial applications are:

- ANSI/ASME Standard: ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

- DIN Standards for Spectacle blind: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638, DIN 2673

- BS Standards for Spectacle Bild and Spacer: BS 4504, BS 4504, BS1 560, BS 10

Definition of Terms used with Spectacle Blind

Ring Spacer or Spacer Ring or Paddle Blank or Paddle Spacer

Spacer Rings are made to match the pipe ID with the same thickness as the “single-blind” that it replaces. During the installation of spacers, the flange and associated piping should be pulled together and a “ring spacer” has to be installed to fill the gap. Normally, a handle is attached to the blank by welding.

Single/ Line Blind or Blank or Spacer Blind or Flange Spade or Paddle Blind

Single-blind is a positive shut-off device that is generally installed along with a valve so as to prevent accidental flow. In general, they fit inside the bolt circle of mating flanges. However, Plastic, Fiberglass, and Cast Iron, are bolted. Single blinds use standard gaskets.

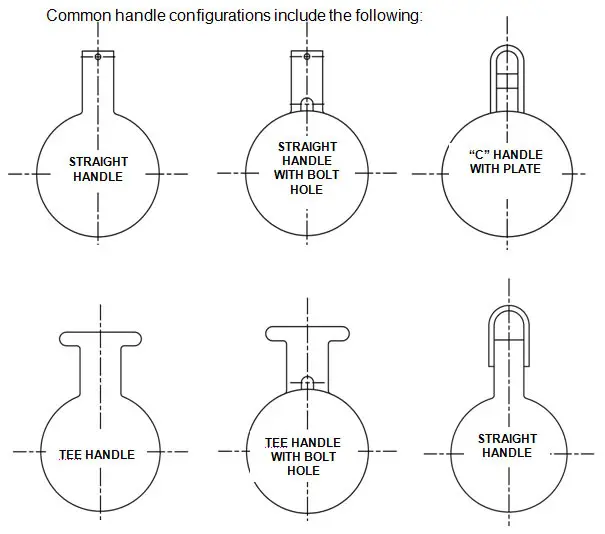

To differentiate between a spacer and blind in the installed line, the handle of the blank is made solid whereas a formed eye or drilled hole is made for the spacer.

Spectacle Blind

A combination of a ring spacer and a single-blind is used as a spectacle blind. As required they are rotated to serve the purpose. When spectacle blinds become too heavy, a pair of paddle blank and paddle spacer is used instead of a single spectacle blind.

Test (Hydrotest/Pneumatic Test/Service Test) Blank

During leakage testing, test blanks are used. Test blanks are specifically designed blanks and used only for testing purposes for the test duration.

Vapor Blind

Similar to a “single-blind”, Vapor Blinds are positive sealing devices used for preventing vapor leakage into a pipeline or vessel. Generally, they are thinner compared to single-blind and normally 1/8″ to 5/16″ (3-8mm) thick.

Jack Screw Flanges

For larger-size blinds, Jack Screw Flange is required. Jackscrew help in spreading the flanges and replacing the spacer/blind or turning of spectacle blind.

Use of Spectacle Blind, Spades, and Spacers

As Spectacle Blind, Spades and Spacers belong to the family of pipeline isolation devices, and they are used to provide flexibility during operation and maintenance. Hence, it is required to consider this during the design of the Piping system. Blanks are normally installed in a horizontal line. On average, spectacle blinds are installed on the following

- At inlets and outlets of rotary and static equipment

- In bypass line

- At the unit battery limit

- Where double isolation is required for high-pressure lines.

Spectacle blinds in Piping Material Specification (PMS)

In the PMS following details need to be clearly specified for spectacle blinds:

- Nominal Pipe Diameter

- Pressure Rating

- Material of construction

- Dimensional Standard and

- Facing type.

Common Spectacle blinds are available in the following facing types

- Raised Face (for high-pressure applications)

- Flat face (for low-pressure applications)

- Male and Female Ring-Joint Blanks (used in conjunction with ring-joint gaskets)

Materials of Spectacle Blind and Spacers

Spectacle blinds and spacers are manufactured from various materials as listed below:

- Carbon Steel Spectacle Blind: ASTM A105.

- Stainless Steel: ASTM A182 F304, F304L, F304H, F316, F316L, F316Ti, F310, F310S, F321, F321H, F317, F347, F347H, F904L.

- Alloy Steel: ASTM A182 F1, F11, F22, F5, F9, F91.

- Duplex Stainless Steel Spectacle blind: UNS S31803, UNS S32750

- Nickel Alloys: Monel 400 & 500, Inconel 600 & 625, Incoloy 800, 825, Hastelloy C22, C276.

- Copper Alloys: Copper, Brass & Gunmetal.

Symbols of Spectacle blinds

The following spectacle blind symbol is used in P&ID to denote spectacle blind.

Difference between Spectacle Blind and Spade and Spacers

Spade and Spacer combinedly are comparable to Spectacle Blind. So, a spectacle blind is the combined form of a spade and spacer. For larger pipe sizes the weight of the spectacle blind becomes too heavy. So sometimes, as the requirement arises, a spade or spacer is used. The word “SPADE” or “SPACER” are stamped on the handle of the spade or spacer to clearly indicate what is installed in the line.

In the installed position the handles of the spade and spacers are visible from the outside. The common handle configurations are provided below in Fig. 5

Few important Considerations for Spectacle blinds

- Spectacle blinds must be accessible from grade, platform, or if below 4500 mm by a portable ladder, or temporary scaffolding.

- The proper weight of the Spectacle blind needs to be considered during pipe stress analysis when near the equipment nozzles.

Few more Resources for you…

“Pipe Coupling”-A short Introduction for the piping professionals

A Literature on Piping Nipples for piping and plumbing industry

Piping Elbows and Bends: A useful detailed literature for piping engineers

Reducers used in Piping Industry: A short literature

Tee Connection: A short literature for piping engineers

Difference between Stub-in and Stub-on Piping Connection

Please clarify: For use of temporary blanks, it is the recommended to use the same material of construction of the mating flanges. Can you site the chapter and verse in the codes

Sir,

We can identify even installed spacer or blind by no. Of holes present on its tale.

If hole quantity is 01, it’s blind and if hole quantity is 02 it’s spacer.

is material marking on spectalcle blind is mandatory?