Fasteners are mechanical devices to rigidly affix or join two or more mechanical items. Fasteners are widely used for mechanical joints requiring dismantling as they usually create non-permanent joints. Mechanical fasteners or fastening hardware are extensively used in various industries including Automobiles, Construction, Aircraft, Agriculture, Machinery and Appliances, Infrastructure, etc. In this article, we will learn the definition of a fastener, Its types, materials, applications, and relevant codes and standards.

What is a Fastener?

A fastener is a broad range of mechanical tools/elements used to hold two or more objects together as a rigid attachment. Fasteners allow for the separation or dismantling of the pieces without suffering any damage. However, they can be used as permanent joints as well. Screws, nuts, bolts, nails, washers, etc are different types of fasteners.

Types of Fasteners

There are different types of fasteners that are used in industrial applications. The most common types of mechanical fasteners are:

Fasteners Type- Nuts and Bolts

Nuts and bolts are one of the most common types of fasteners available for industrial use. They work together in tandem and hold two or more components together. The bolt is inserted through the bolt holes between the components and then the nut is fastened on the other end. There are various types of nuts and bolts as mentioned below.

Types of Nuts:

Nuts have internal threads and are always used with a mating bolt. The most popular types of nuts are:

Hex Nuts: The most common variety of nuts, Hex Nuts consist of a hex shape (six-sided) with internal threads. They can be easily tightened or loosen with a wrench accessing from any angle.

Coupling Nuts: They are also hex-shaped nuts. This hollow-threaded fastener joins two male threads together and is also known as an extension nut. They are widely used for installing plumbing pipes.

Lock Nuts: Locknuts are specially designed fasteners to prevent loosening due to vibrations. Also known as prevailing torque nuts, lock nuts find uses in automotive and washing machines where vibration problems have the tendency to loosen parts.

Square Nuts: Feature a square shape, square nuts are the oldest type of nuts with four sides. They are the best for the greater surface area making the fastener stronger and reducing damage from rough edges. Usually, square nuts are used in furniture and metal channel applications.

Flange Nuts: Having a wide, serrated flange on one end, flange nuts serve a similar function as a washer but it does not provide any added movement. They are also known as Tee nuts.

Wing Nuts: Having two projected pieces, wing nuts can be easily loosened or tightened using hands without tools. This type of fastener is good for applications requiring frequent tightening and loosening. Click here to learn more about wing nuts.

Slotted Nuts: In slotted nuts, sections are cut out to create a locking mechanism with the help of a cotter ping.

U-Nuts: Reliable and strong, U-nuts are made from one piece of rolled thread. They are used to hold metal sheet panels together.

Speed Nuts: Speed nuts have two metal pieces that work as one. Also known as sheet metal nuts, speed nuts do the job of both a nut and a locking washer.

Push Nuts: Push nuts can distribute loads easily that reduce surface stresses. They are installed with a special nut driver and used to secure unthreaded bolts and other fasteners.

Jam Nuts: Jam nut is small size nut that is half as tall as hex nuts. They are widely used where space has limitations to use hex nuts. They can easily be fastened onto a bolt without applying torque or force.

Axle Nuts: Also known as cap nuts or dome nuts, axle nuts hide the bolt edges and provide a seamless appearance. It provides a nice surface finish and finds use in electrical panels, stereo cabinets, etc.

Castle Nuts: Castle nuts have notches at one end through which a pin can be inserted to fix the nut’s position. They are used when the torque requirements are low.

Some other types of nuts are

- Rivet Nuts

- Weld Nuts

- Barrel Nuts

- Shear Nuts

- Tri-Groove Nuts

- Keps-K Lock Nuts

- Knurled Thumb Nuts

- Wheel Nuts, etc

Types of Bolts

Many different types of bolts are available in the market. The most common types of bolts that are used for industrial applications are:

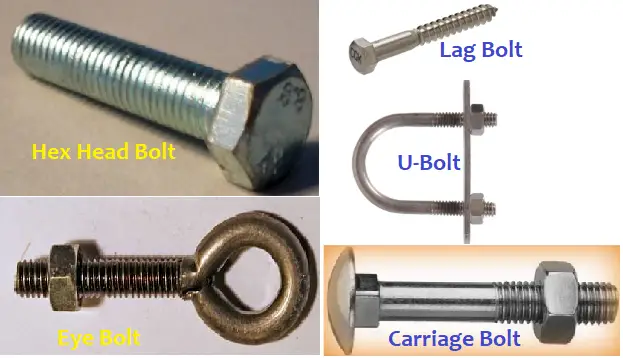

Carriage Bolts: Having domed or countersunk heads, Carriage bolts use a square component under the head to keep the bolt from moving (pulling through) while tightening the nut. Carriage bolts are self-locking bolts and are usually used to attach metals to wood.

Hex Bolts: They have six-sided heads with machine threads extended halfway or up to the bolt head. Hex bolts find wide construction and machinery applications as they can be easily tightened using a wrench. Also popular as hex cap screws, hex bolts work with a tapped hole or a nut.

U-Bolts: U-bolts are shaped like the letter “U” and have screw heads on both ends. The bent section of the U-bolt is unthreaded. They are extensively used in piping, plumbing, and HVAC works to secure the position of pipes and tubes without making any holes in them.

Eye-Bolts: Eye bolts are threaded on one end and a loop at the other.

Lag Bolts: These bolts are used independently without a nut. Extremely sturdy and tough Lag bolts can handle a lot of weight. They are used for heavy-duty jobs like installing frames, framing lumber, etc.

Flange Bolts: For even distribution of the loads, Flange Bolts include a circular flange beneath the head.

Allen Bolts: Also known as Socket head bolts, Allen bolts have a hexagonal socket for use with Allen wrenches. These types of fasteners need less space.

There are a few other variations of bolts like:

- Plow bolts: for heavy-duty applications, such as heavy equipment, with non-protruding heads.

- Square-head bolts: having square heads that offer an easier grip for wrenches.

- Peta bolts with 5-sided heads.

- Double-end bolts resembling a threaded rod.

- Shoulder bolts or Stripper bolts.

Fasteners-Washers

Sometimes washers are added in between nuts and bolts to distribute the fastener’s load evenly over the material surface. A washer is a flat circular disc with an opening in the center. Washers can be metallic or can be made from non-metals. Other main purposes of washers are:

- Isolation of Components

- Reduction of leakage

- Alleviation of friction, and

- Prevention of loosening during vibration.

Some common types of washers are:

- Plain Washers: Plain washers are used for load distribution and isolation purposes. Plain washers can be of various types like:

- Round and thin Flat Washers for general use.

- Torque Washers for use in woodworking projects.

- Fender Washer used in car fenders.

- Finishing Washers used with countersank screws, and

- C-washers

- Spring Washers: These types of fasteners act like a spring as they develop axial flexibility to make the joint more elastic. This can avoid unintended loosening during vibration. The main types of Spring Washers are:

- Belleville Washer

- Crescent Washer

- Dome Spring Washers, and

- Wave Spring Washers

- Lock Washers: This type of washer uses various mechanisms to prevent nuts, screws, and bolts from loosening. Lock washers are much better than spring washers and can be of the following types:

- External tooth lock washer

- Internal tooth lock washer

- Split lock washer, and

- Tab washer

- Beveled Washers: These washers add stability when attaching unparallel surfaces.

- Structural Washers: Usually thicker, Structural washers are used in heavy-duty applications.

Fasteners-Screws

Screw fasteners are the most versatile type of fasteners. It’s very simple to use. One needs to drill a pilot hole in a material and then using a screwdriver the screw can be easily installed in place. They generally have male threads that start from the tip. Screws are usually self-threading and create the thread during installation.

They come in various types and sizes like:

Self-Drilling Screws: Also popular as self-tapping screws, self-drilling screws create the required internal thread while installing it. It contains a fully threaded shaft.

Machine Screws: These types of fasteners are most widely used for machinery applications. It comes in a variety of tip shapes and heads with a slotted socket on the head to tighten it. They are of uniform thickness and don’t taper off at the bottom.

Sheet Metal Screws: With an extremely sharp tip, sheet metal screws are used to fasten two metals together. They have a flat or rounded head.

Other types of Screws are:

- Deck screws having a self-tapping design.

- Wood screw having coarse thread and tapered head.

- Grub Screws without a head used to prevent rotation or movement between two parts.

- Masonry screws having flat tips and hex-head designs.

- Countersunk screw

- Hex lag screw

- MDF screws

- Drywall screws

Nails as Mechanical Fasteners

Nails are the oldest type of fasteners used since ancient times. It is still used as an everyday household item. Nails do not have threads and usually have less power than screws. The most widely used types of nails are:

- Common nails having a thicker shank.

- Box nails with a diamond point tip.

- Roofing nails with a wide head.

- Framing nails are specially designed for flush installation and easy concealment.

- Brad nails for easily blending into wood trims.

- Flooring nails for use with flooring materials.

- Drywall nails for reduced slippage.

- Finishing nails with small flatheads.

Anchors as Industrial Fasteners

Anchors are a particular type of fastener that is used to connect something to a material like concrete or drywall. They embed themselves in the material and hold the object in place. Various types of anchors are used to serve different types of functions. Some common types of well-known anchors are:

- Internally threaded anchors

- Externally threaded anchors

- Acoustical wedge anchors

- Masonry screw and pin anchors

- Bonded anchors

- Screw anchors

- Double expansion shield anchors

- Hollow wall anchors

- Drop-in anchors

- Sleeve anchors

- Plastic anchors

- Drive anchors

Mechanical Fasteners-Rivets

Rivets create a permanent joint between objects and are hence known as permanent fasteners. Consisting of a cylindrical shaft with a head on one end and a tail on the other, Rivets offer great support against shearing forces. This type of fastener is lightweight and remarkably durable. A unique tool popular as a rivet gun is required to install rivets. Rivets can not be reused after removal. Some common types of rivets include:

- Blind rivets

- Pop rivets (Closed-end, Open end, Countersunk)

- Semi-tubular rivets

- Large flange rivet

- Solid rivets

- Tri-fold rivet

- Split rivets

- Drive rivets

- Structural rivets

- Colored rivets

- Multi-grip rivets.

Fastener types-Pins

Pins are unthreaded mechanical fasteners usually inserted through preformed holes. The most common types of pins for industrial usage are:

- Dowel pin

- Slotted pin

- Coiled pin

- Roll pin

- Grooved pin

- Split pin

- Wedge pin or tapered pin, known as cotter.

Retaining Rings

Retaining rings are a non-permanent type of metallic fasteners used to hold multiple parts together. It usually consists of spiral, semi-circular metal pieces. Retaining rings are employed in many applications in machinery and housing components.

The various types of retaining rings that are found are:

- Constant section retaining ring

- Snap retaining ring

- Tapered section retaining ring

- Axially assembled retaining rings

- Spiral retaining ring

- Radially assembled retaining ring

- Circular push-on

- Bowed-E retaining rings

- External shaft retaining rings

- Self-locking retaining rings.

Inserts

Inserts perform a range of tasks as mechanical fasteners. They are usually used for reinforcing joints, fixing eroded internal threads, used as keys in rotating machinery, or fastening anchor bolts to hanging pipelines.

Inserts are available in different forms like:

- Keys in shaft key-ways

- Threaded rod

- Unthreaded rod

- Helical threaded inserts

- Keystock

Other Types of Fasteners

There are many other types of fasteners that are used. Some of those fasteners are

- Clamps

- Staples

- Straps

- Hooks and Eyes

- Twist ties, etc

Fastener Materials

Fasteners are made of a variety of materials. Proper selection of a fastener material should be based on the working environment, weight, expected life, reusability, magnetic properties, and reusability. Common materials that are used for manufacturing fasteners are:

- Steel

- Brass and Bronze

- Copper

- Nickel

- Aluminum

- Stainless Steel

- Inconel

- Monel

- Titanium

- Nylon and Plastics

Fastener Codes and Standards

Widely used standards for industrial fasteners are:

- ASME B18.6.3 for Machine Screws, Tapping Screws, and Metallic Drive Screws (Inch Series)

- ANSI B18.6.1 for Wood Screws (Inch Series)

- ASME B18.6.2 for Slotted Head Cap Screws, Square Head Set Screws, And Slotted Headless Set Screws (Inch Series)

- ASME B18.24 for Part Identifying Number (PIN) Code System Standard for B18 Fastener Products

- ASTM-A31 for Steel Rivets and Bars for Rivets, Pressure Vessels

- ASTM-A320 for Alloy Steel Bolting Materials for Low-Temperature Service

- ASTM-A193 for Alloy-Steel and Stainless Steel Bolting Materials for High-Temperature Service

- ASTM-A194 for Carbon and Alloy Steel Nut for Bolts for High-Pressure and High-Temperature Service

- ASTM-A307 for Steel Bolts and Studs, 60,000 PSI Tensile Strength

- SAE-J78 for Steel Self-Drilling Screws

- SAE-J81 for Thread Rolling Screws

- SAE-J82 for Mechanical and Quality Requirements for Machine Screws

- SAE-J238 for Nut and Conical Spring Washer Assemblies

- SAE-J482 for Hexagon High Nuts

- SAE-J492 for Rivets and Riveting

- SAE-J493 for Rod Ends and Clevis Pins

- SAE-J773 for Conical Spring Washers

- SAE-J891 for Spring Nuts

- SAE-J892 for Push-On Spring Nuts, Inch Series- General Specifications

- ANSI-B1.1 for Unified Inch Screw Threads (UN and UNR) Thread Form

- ANSI-B18.1.1for Small Solid Rivet

- ASME B18.18 for Quality Assurance For Fasteners

- ANSI-B18.1.2 for Large Rivets

- ANSI-B18.22.1 for Plain Washers

- ASME B18.3 for Socket Cap, Shoulder, Set Screws, and Hex Keys (Inch Series)

- ISO 2339, ISO 7089, ISO 7090, ISO 2340

- DIN 125, DIN 126, DIN 1444

- BS4464B

Fasteners Selection Criteria

A variety of factors need to be considered during fastener selection for industrial applications. Some of them are

- Material of construction (stainless steel, carbon steel, or alloy steel).

- Materials to be joined.

- Environment, including temperature, water exposure, and potentially corrosive elements.

- Installation process.

- Re-usability.

- Weight restrictions.

- The applied load on the fastener.

- The stiffness of the fastener.

- Special process conditions (special coatings or plating).