Piping Design Engineers, Piping Layout Engineers, or Piping Designers are piping professionals who design the piping network of the complete plant. Piping Designing means deciding the overall plant layout, the equipment location, the Plot Plan, the pipe routing, the development of the 2D or 3D CAD models, and finally the piping isometrics. Broadly Piping Design Engineers or Piping Designers perform a maximum of the piping design work scope. A smaller part is performed by Piping Materials Engineers and Piping Stress Engineers in a different manner.

Piping design is a very critical activity. It requires knowledge of various aspects. As the maximum part of any plant is covered by piping and equipment and structures are connected to piping, it is very important that piping design must be proper. Failure to do any single part can cause serious damage to the plant. So piping engineers and designers should follow their duty with utmost care. In the following paragraphs, I will present a list of the most basic points that a good piping designer or piping design engineer should know.

Pipes, Pipe Fittings, Piping Components

All piping designers /piping design engineers should be aware of the broad spectrum of piping and piping-related items. This translates to

- different types of fittings (elbow, tee, reducer, etc.),

- different piping schedules,

- variety of common piping materials (CS, LTCS, SS, DSS, HDPE, GRE, etc.),

- flange pressure class ratings (150#, 300#, 600#, 900#, 1500#, etc.) and

- various types of different valves and their functions.

Codes, Standards, Specifications, Guidelines

All piping design engineers/ designers should be aware of important design points from relevant Codes (ASME B31.3, ASME B 31.1, etc. as applicable), Standards (API or ASME standards), Specifications (Company Material Class and other specifications), and Guidelines (Local Company guidelines like Shell DEP rules, Norsok standards, etc). The more conversant with such documents the piping engineer/designer is, the less time he will be taking for designing activity.

Interaction with other Engineering groups

All piping designers/ piping layout engineers need to understand the activities and roles of all the other engineering and design groups on the project. He should be aware of the complete workflow process. These include Process, Static Equipment, Rotary Equipment, Civil, Structural, Electrical, and Instruments/Control Systems. All these groups contribute to a large extent to Piping’s success and vice versa.

Piping Design Execution

The success of Piping Design activities is closely linked to P&IDs, equipment GA drawings, instrument drawings, stress analysis, and structural support design. So a good piping design engineer/piping designer must be able to identify the areas where the piping design is being held up.

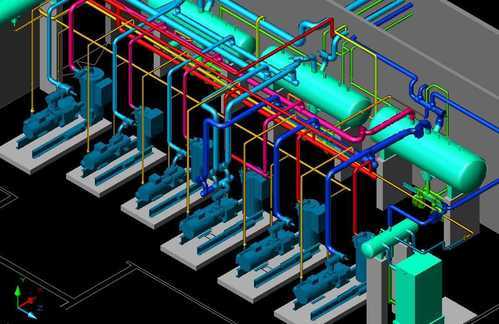

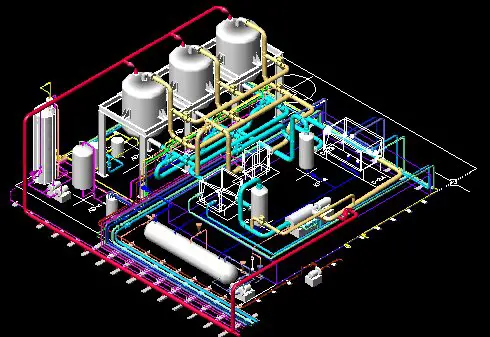

Software Tool Knowledge

In recent times all piping design activities are performed in various commercial software like PDS, PDMS, SP3D, E3D, AutoCAD, etc. So the design engineer should be knowledgeable in operating the required software for the project. He must also be aware of other software like Navisworks, SPR, MS-office, etc.

Working knowledge of Process Documents

All piping designers and engineers need to be able to read and understand one of the most basic process documents called P&ID (Piping and Instrument Diagram) or PEFS (Process Engineering Flow Scheme). Piping Design Engineer should know how to extract data from P&ID and use those in Piping Design. Throughout the complete detailed design phase, P&ID will be the master navigator of piping design.

Basic Process Variables

The design engineer/designer must be well aware of a few basic process variables like pressure, temperature, flow, and level. Also, the instrumentation used to regulate and/or measure these variables are a very important parameter for piping designer/layout engineer.

Drawing Content

All piping engineers and designers must know to present their designs following company standard templates. Drawing content and standard dimensioning practices must be pre-decided in order to clearly communicate the designs to construction and fabrication personnel.

Preliminary knowledge of Process Equipment

Knowing and understanding different types of process equipment (Vessels, Pumps, Heat exchangers, Reactors, Fired Heaters, Compressors, Flares, Storage Tanks, etc) is an added advantage for all piping designers/engineers. They should be aware of the piping-related issues for each type of equipment and piping design rules governed by the equipment. The piping engineer/ designer should know that a few types of equipment have nozzles fixed by the manufacturer and for others, the piping designer should locate the nozzles. Preliminary knowledge of the operational, maintenance, and installation/construction issues for each piece of equipment is very important.

Piping from Equipment

All the piping design engineers and piping designers should know the piping rules to be followed for different kinds of equipment along with maintenance/operational space requirements.

Allowable pipe spans for pipe supporting

All designers should know the use of piping support spans and guide spans for preliminary pipe support. Piping with different materials and pipe schedules has different spans. Also, these spans may change based on temperature and fluid being transported.

Preliminary Knowledge of Piping expansion

It’s always advantageous to have preliminary knowledge of the thermal expansion of different piping materials for different temperatures. In recent times various software like Pipe Data Pro easily provides these data. However, knowing how to use that data efficiently is very important. The thermal growth or thermal movement with an increase or decrease in temperature must be allowed for and incorporated into the overall design. Care should be taken that one line is not hitting the other line and sufficient spacing should be provided. Additionally, these expansion data will be used for expansion loop design and shoe/support length design.

Designing and Locating Piping Expansion loops

All piping design engineers and piping designers should know the use of simple rules and methods for sizing expansion loops for the most common sizes, schedules, and materials.

Basic knowledge of flexibility while pipe routing

All piping engineers/ designers must understand the concept of adding flexibility. Normally critical lines are checked by Piping Stress Engineers to have the required flexibility. But non-critical lines are routed by piping design engineers or piping designers. Hence, he must be aware of providing flexibility while pipe routing.

Impact of Piping Insulation Requirement

The piping engineer should know the impact of insulation on piping, mainly on supporting and support loading.

Heat Tracing

All piping designers/engineers should be aware of the purpose of process heat tracing, know the different methods (Jacketing, Tracer Tubing, or Electric), Tracer commodity (Steam, Oil, Hot Water, etc.), and Tracer system requirements and be able to design heat tracing circuitry.

Piping Deliverables

All piping professionals should know the purposes of each of the piping deliverables, like plot plans, key plans, piping plans and sections, GA Drawings, and isometrics.

Impact of Weight and loads

The effects of weight and loading should be known to every piping design engineer/piping designer. They need to have access to basic weight tables for all the standard pipe schedules, pipe fittings, flanges, and valves for steel pipe.

Specific Pipe Routing Rules like Rack Piping, Vessel piping, Exchanger Piping, etc.

All piping engineers or designers should know specific considerations for equipment piping, their support, impact on nozzle loading, etc.

Fabrication and Construction methods

Understanding shop spool fabrication, modularization, and field erection construction methods are important for a good piping engineer or piping designer.

Plant Economics

Last but not the least, Optimized and Economic pipe routing is very important to reduce project costs and increase profitability. Hence, piping design activities must be performed to be aware of the economic aspects.

Professionals, who possess such knowledge and applies this knowledge in project work constantly is undoubtedly very good piping design engineer or piping designer, or piping layout engineer.

So complete your vision about what a piping engineer ir designer must know and to account when requires.

Thanks for sharing.

Hello

Mr/Mrs

I need to help you design Education Piping

I work at Refinery Tabriz

Thank you so much

I am interested to learn piping engineering.

Help me for that

I myself am passionate about the whole process in piping, starting in 1985 from labor position on new construction working up to Piping Designer for major companies here in Houston, Tx. I look back at my construction days from a pipefitter view and would say “what are these piping designers thinking of” reason is back then accountability (piping never fit) was second and completing the piping was first, that has helped me as a Piping Designer now, also for revamp work which we have been doing here, is the Hot-taps, cold taps, stopples also part of the designing along with weld placement as a pipefitter the welders appreciate vertical welds verses horizontal but a good welder can do both as needed.

Most of engineers learn modelling software and think that it is ultimate. They don’t become e design engineer at all.

For eg. preparation of tank farm layout as per OISD they cannot do. Modeller must learn pipe sizing, thk.calcultions, equipment sizing etc.