A hydrostatic test or hydro test is a widely used method to ensure leak tightness and safety of pressure vessels, piping systems, pipeline systems, plumbing systems, tanks, boilers, cylinders, and other system components. The test is performed by subjecting the material to a predecided controlled pressure known as test pressure and then checking the material response under pressure. It is a type of pressure testing performed before commissioning. In this article, we will learn about the hydrostatic testing procedure of piping systems in detail.

Part A: Pressure Test (Leak Test) in Piping

What is a Pressure Test in Piping?

A pressure test of pipes is always required for a new pressure piping system before use or an existing pressurized system after repair or alteration to ensure the following:

- Safety

- Reliability of operation

- and leak tightness of pressure systems

- Also, the last physical quality test in the fabrication process

Subsequent to repairs and heat treatment and prior to the initial operation or commissioning of any plant it has to be ensured that there is no evidence of leakage by Pressure Testing. As the main aim of performing pressure testing in piping systems is to ensure leak tightness, it is also known as the leak test of piping.

When to Perform a Pressure Test/Leak Test in Piping?

As per the governing code, a pressure test has to be performed on the piping system after all hot works have been completed on a certain piping system. Here the term hot work means everything related to welding or post-weld heat treatment (PWHT). PWHT also has the potential of degrading the mechanical properties of piping, in case not addressed properly. And this is the reason why the code calls for NDT after the PWHT operation.

In case after carrying out pressure testing, some modification has to be made requiring hot work, which calls for a retest as per code. Here code specifies that the minor repairs/modifications may be waived off provided adequate measures have been taken to ensure sound construction. Now this decision as to which repairs or modifications may be waived off should be taken very carefully. Normally, the maximum extent of repairs not requiring retesting shall be the tack welding of any piping support or pad. Anything else shall be done following a retest.

Pressure testing and conducting 100% radiography or ultrasonic inspection shall not be interchanged. In case carrying out of hydrostatic or pneumatic test stands impractical then 100% radiography or ultrasonic testing may be performed but in addition to this, it is advisable to check that the whole piping and its components have been supplied against acceptable ASTM standards and required test certificates are available.

Conducting 100% radiography of all the weld joints assure that your weld joints are defect-free but can never provide you with the assurance of mechanical integrity of a system.

This is also to be noted that radiography / ultrasonic inspection shall also not be waived off if the pipeline is to be hydrostatically tested. This may pose an additional safety risk during the test. Moreover, some defects in the weld zones may prove to be detrimental way after being taken in service due to severe extended service conditions.

Types of Piping Pressure Testing

In the process piping industry, two methods are widely used for pressure testing of piping or equipment. They are

- hydrostatic test or hydro test and

- pneumatic test

Pressure tests (both hydrostatic and pneumatic) must always be performed under controlled conditions, following an approved test plan, and documented in a test record. A single approved test plan could be used for several similar tests, but for each test, a separate test record is required.

The Basis for Pressure Test Method Selection

Normally the following basis is followed in the process piping industry for the selection of hydro or pneumatic tests in piping.

- If the fluid handled by the piping system is liquid then the pipe must be hydro-tested.

- If the fluid handled is vapor or gas then the internal design pressure dictates the testing method. For pipe design pressure 10 bar and above the pipe is hydro-tested. For pipe design pressure below 10 bar pipe is pneumatically tested.

- If the fluid handled is steam then hydro testing is suggested.

- If the fluid handled is a two-phase flow then hydro testing is suggested. However, for big-size flare headers, pneumatic testing is performed.

- If hydrostatic testing has the potential to damage the internal lining or insulation, then pneumatic testing is suggested.

- When the water (moisture) used in the hydro test has the potential to contaminate the process, a pneumatic test may be opted for.

- If the Piping is not designed for Hydrostatic pressure test conditions, then the pneumatic test is performed.

- Instrument-air lines are pneumatically tested.

Part B: Hydrostatic Test or Hydrotest in Piping

What is a Hydrotest or Hydrostatic Test?

Hydro test or Hydrostatic test is a type of pressure test performed on piping, pressure vessels, and other pressurized systems to check system integrity under pressure conditions. A hydrostatic test is performed by using water as the test medium.

How to Calculate Hydrotest Pressure in Piping? | Piping Hydrostatic Test Pressure Calculation

ASME Code B 31.3 provides the basis for test pressure. The minimum hydrostatic test pressure for metallic piping shall be as per the following equation:

Pt=1.5*Pd*(St/Sd)

Here,

Pt=the minimum test gauge pressure

Pd=internal design gauge pressure

St=allowable stress value at the test temperature

Sd=allowable stress value at design temperature.

The maximum allowable value of St/Sd is 6.5

Note that, ASME B31.3 provides a provision to reduce the hydrostatic test pressure in piping under certain conditions. Quoting the Process Piping code ASME B31.3 the rules for reduced test pressure are:

“If the test pressure would produce a circumferential or longitudinal stress (based

However, the hydrostatic test pressure must not be less than the design pressure.“

on minimum pipe wall thickness) in excess of yield strength at test temperature or is greater than 1.5 times the component rating at test temperature, the test pressure may be reduced to the maximum pressure that will not exceed the lesser of the yield strength or 1.5 times a component rating at test temperature.

Hydrostatic Test Duration

Normally every EPC company has its own standard for the duration of tests. However, the recommended practice is that a QC inspector has to walk through the whole piping system and check for leaks. Every single length of piping, welds, and bolted connections shall be visually examined for any leakage. The duration of this activity varies with the span of the piping system. For a larger piping system time taken for this activity is enough to clear the pressure test. In the case of a piping system having a smaller span, 1 hour time may be made as standard practice for hydrostatic testing. For the Pneumatic test, the test time is far less.

As per ASME B31.3, The leak test pressure has to be maintained for at least 10 min and then all joints and connections shall be examined for leaks.

Procedure for Hydrostatic Testing

The following are the basic steps involved in the hydrostatic testing of piping systems:

- Preparation: Before testing can begin, the system must be cleaned and dried to remove any debris or moisture that could interfere with the test. All valves, flanges, and fittings must be properly secured and tightened to prevent leaks during the test.

- Filling: Once the system is prepared, it is filled with water or another suitable test fluid. The fluid is usually pumped into the system until it is completely filled and all air is purged from the lines.

- Pressurization: After the system is filled, it is pressurized slowly and gradually to the required test pressure. The pressure is usually increased in increments to allow for any leaks or weaknesses to be detected before reaching the full test pressure.

- Stabilization: Once the system has been pressurized to the required test pressure, it is held at that pressure for a specified period of time to allow for any leaks to be detected. The duration of the test may vary depending on the type and size of the system being tested.

- Inspection: While the system is pressurized, it is inspected for leaks or other defects using a combination of visual, audible, and/or electronic methods. Any leaks or defects that are detected must be repaired before the system can be considered safe for use.

- Depressurization: After the test is completed, the system is slowly depressurized to prevent sudden changes in pressure that could damage the system. The test fluid is then drained from the system and properly disposed of.

- Documentation: Finally, a detailed report of the test results is prepared, including the pressure and duration of the test, any defects or leaks that were detected, and any repairs that were made. This documentation is important for maintaining records of the system’s safety and compliance with regulatory requirements.

Hydrotest Fluid

As the name signifies, the test has to be performed using clean potable water free from suspended solids. However different codes specify different requirements for water quality. Hence, hydro tests need to be performed following those instructions.

Hydrotest System Preparation

The piping network and the connected equipment must be prepared thoroughly before proceeding with pressure tests like hydro or pneumatic testing. Codes like ASME B31.3/ ASME B 31.1 and local company instructions normally provide guidelines for such preparation.

Piping systems that are normally open to the atmosphere, such as drains, vents, discharge piping from pressure-relieving devices, sewers, and stack downstream of the seal drum, need not be subjected to the piping test pressure.

For some countries, The provincial local inspector shall be notified at least 48 hours in advance of pressure testing of piping under the jurisdiction of the provincial safety code for witnessing at his/her option.

The following equipment shall be excluded from all piping pressure tests:

- Vessels and tanks

- Heat exchangers

- Rotating machinery, such as pumps, compressors, and turbines

- Equipment and Supplier furnished piping specifically recommended by the manufacturer not to be tested

Underground portions of piping systems may be tested and covered before testing aboveground portions.

Roughly, The following steps should be followed for preparing the piping system for leakage testing.

Comparison of P&ID/PEFS and Isometric Drawing

The first step is to compare the piping isometrics with the P&ID drawings to check if any discrepancy exists. All valve types, flow directions, branch tie-ins, and any material changes, etc are reviewed thoroughly. In-line components are verified and ensured that they are able to withstand the test pressure.

Thorough Inspection before testing

All sorts of ultrasonic and radiographic inspections or checks must be carried out before the actual pressure test is started. Conducting 100% radiography of all the weld joints assures that your weld joints are defect-free but can never provide you with the assurance of the mechanical integrity of a system. This is also to be noted that radiography / ultrasonic inspection shall also not be waived off if the pipeline is to be hydrostatically tested.

Joints shall be exposed

All joints, welds (including structural attachment welds to pressure-containing components), and bonds shall be left uninsulated and exposed for examination during leak testing as per Section 345.3.1 of ASME B31.3, except that joints previously tested in accordance with this Code may be insulated or covered.

Provision of Temporary Supports

If required Pipings designed for vapor or gas services shall be provided with additional temporary supports, to support the weight of the test liquid as the test liquid is heavier than the service fluid.

Spring Supports in Piping System

All Spring supports shall be kept in locked condition during hydrostatic testing. Holding pins shall not be removed from spring supports until testing is completed and the system is drained. Care shall be taken to avoid overloading any parts of the supporting structures during hydrostatic testing.

Instruments

- All in-line Instruments shall be either removed or blocked prior to hydro testing to prevent damage during hydro testing (e.g. meters).

- Instrument take-off piping and sampling system piping, up to the first block valve, shall be tested with the piping to which it is connected.

- Instrument lead lines, between the first block valve and the instruments to which they are connected, shall be pressure tested to the test pressure of the associated piping. Testing may be performed separately or at the same time as the piping is tested, but the instruments shall be disconnected.

Hydro test for Piping with Expansion Joints

If there is an expansion joint in the piping system under the leakage test, the following criteria shall be applied.

- An expansion joint that depends on external main anchors to restrain pressure end load shall be tested in place in the piping system.

- A self-restrained expansion joint previously shop-tested by the manufacturer

- A piping system containing expansion joints shall be leak tested without temporary joint or anchor restraint at the lesser of

- 150 % of design pressure for a bellows-type expansion joint, or

- the system test pressure is determined in accordance with para. 345

In no case shall a bellows-type expansion joint be subjected to a test pressure greater than the manufacturer’s test pressure.

- When a system leak test at a pressure greater than the minimum test pressure specified in (c), or greater than 150% of the design pressure within the limitations of para. 345.2.1(a) is required, bellows-type expansion joints shall be removed from the piping system, or temporary restraints shall be added to limit main anchor loads if necessary.

Limits of Tested Piping

Equipment that is not to be tested must be either disconnected from the piping or isolated by blinds or other means during the test. A valve may be used provided the valve is suitable for the test pressure.

Rotating Machinery

Rotary machinery, such as pumps, compressors, or steam turbines, have lube and seal oil systems that could be impaired by the presence of water. These systems shall not be subjected to the piping test pressure.

Test Water

Clean water that will not corrode and/or damage the test system shall be used for hydrostatic tests. If municipal water is not available, supply water may be obtained from a native water supply. Water containing silt or suspended material shall not be used, and a suitable filter with 40 mesh should be provided in the filling line. A mixture of glycol-water shall be used where the ambient temperature may reach less than 0°C (32°F) during testing or prior to dry-out

Temporary Spades and Blanks

If Temporary spades and blanks are installed for testing purposes, those must be designed to withstand the test pressure without distortion. The presence of spades shall be clearly visible during testing. The recommended practice is to use standard blind flanges as per ASME B16.5 or B16.47 and spades acc. to ASME B16.48.

Check Valves

Check Valves shall have the piston or flap removed for testing, where pressure can not be located on the upstream side of the valve. The locking device of the flap pivot pin shall be reinstated together with the flap and a new cover gasket shall be installed after the completion of the test.

Completion of Hot Work

Wherever applicable All hot works, related to welding or the post-weld heat treatment have to be completed before the Hydrostatic test.

Installation of Barriers

It is necessary to install safety barriers around the piping system under test prior to starting pressurization related to testing. Public Address announcements and access restriction procedures such as permits to work shall be implemented. Under no circumstances should anyone other than an authorized person be allowed within the safety barriers.

Control Valves

Prior to the leakage test, Control Valves and soft-seal block Valves shall be removed from the piping and replaced with pipe spools. However, All welded Valves need to be tested along with pipings otherwise Radiographic Testing of golden joints (welded) will be required.

Physical Inspection

Prior to the pressure test following should be checked :

- All gravity supports installed.

- Proper pipe routing.

- Vents or other high point connections shall be opened to eliminate air from and plugged during the test.

- lines that are to receive a hydrostatic test.

- Completed and torqued flanges with no missing bolts or gaskets.

- Proper material type is verified using color codes or markings, and heat numbers are recorded if required by the codes.

- Correct valve type and orientation.

- Vents and drains were installed to allow proper filling and draining

- When a pressure test is required to be maintained for a period of time during which the testing medium in the system would be subject to thermal expansion, the provision shall be made for the relief of any pressure greater than the maximum test pressure.

- All required piping stress relief, weld examinations, and welding documentation are completed and acceptable. A relief valve is to be added such that the test pressure is not exceeded beyond a safe amount.

- When conducting tests at freezing temperatures, the test shall not take more than 4 hours, and special precautions, such as using a glycol/water mixture, shall be observed to avoid freezing damage

Some important points to consider while hydro-testing of piping:

- The tower overhead lines which are normally hydro-tested shall be decided by the pipe stress engineer whether to hydro-test after erection or at grade, based on the capacity of the standard clip available as per engineering specification for pipe supports.

- During the hydro test in the case of big-bore, it should be decided first that the line is to be hydro tested on rack or grade if the hydro test is done on the rack, the hydro test load should be considered in case of vapor lines while providing structure/rack loading information.

Hydrotesting Documentation

The individual system documentation i.e. test pack shall be available prior to any testing and shall include information such as test limits, test pressure, test medium, duration, test blinds, blind flanges, vents, and drains.

The use of marked-up P&IDs coupled with isolation registers should be utilized to identify the locations of blinds, Valves, vents, and drains.

Records shall be made of each piping system test. In general, these records shall include the following information:

- Date of test

- Identification of piping system

- Test medium

- Test pressure

- Minimum ambient temperature

- Test medium temperature

- Certification by examiner

- Test duration

- Pipe standards or specifications for the test

- Pressure and temperature recording charts and logs

- Location and cause of leaks/failures

- Repair procedures used in the event that the pipe leaked or failed

- Test results

- Name of the test operator

- Minimum metal temperature (if applicable)

- Test gauge calibration date

Forms, when completed, shall be retained in the Construction Contractor’s QC file as a permanent record.

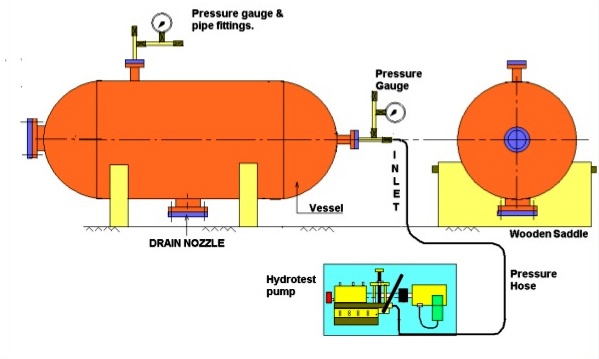

Hydrostatic Testing Equipment

Testing equipment such as pumps, manifolds, pressure, and temperature recorders, and pressure gauges should be within calibration/certification (as per company procedures) and connected to the lowest convenient connection within the system to ensure the best results.

Hydrostatic Testing Problems

Even though proper industry-approved methods are followed for pressure testing, still due to some negligence hazards do happen. Some of the most common reasons for failures during hydro tests and pneumatic tests are:

- Over pressurization

- Operator error

- Inadequate equipment

- Poor component design

- Improper isolation of the tested system from equipment or remaining parts of the system.

- Inadequate repairs

So it is always a good idea to follow safe work practices for Hydro testing. The below-mentioned steps can be followed to avoid hazards of Pressure Testing:

- Prepare a standard operating procedure (SOP) for the hydro test or pneumatic test following the latest applicable code

- Developing a checklist using the sop and sticking to it.

- Train the involved personnel indicating the potential hazards and safety measures.

- Develop a Pre-test safety plan and conduct a pre-test safety briefing just prior to hydro testing.

- Perform a Walk-down inspection following the checklist to ensure all hydro test checkpoints are taken care of.

- After the hydrostatic test, gradually release the pressure and drain the system.

Difficulties with Hydrostatic Testing

- Supply & disposal of water, disposal of fluid additives

- A water leak can cause equipment damage

- Freeze susceptibility

- Structural support limitations

- Contamination

- Operational impacts – process contaminant

- Affect dry-out of internal refractory linings

Piping Hydrotest Checklist | Hydrostatic Test Checklist

The following section provides a sample of the hydro test checklist to inform the major points that must be considered.

| Hydrotesting Checklist | ||||

| Pre HydroTest Checklist | ||||

| Sr No | Description | Complied | Not Complied | Remarks |

| 1 | All Affected people like the Owner, Managers, Workers, and Suppliers, informed | |||

| 2 | Test pressure and duration received or estimated | |||

| 3 | Standard Operating Procedure identified | |||

| 4 | The Pre-test safety plan completed | |||

| 5 | Required workers properly trained | |||

| 6 | Test Equipment inspected, calibrated, and certified | |||

| 7 | Test Temperature verified | |||

| 8 | Test area barricaded and warning signs posted to keep non-essential members outside the hydro-test zone | |||

| 9 | A walk-down inspection performed | |||

| 10 | Hydrotest system preparation proper | |||

| 11 | Vent Valve, Block Valve closed | |||

| 12 | All joints are exposed, No insulation | |||

| 13 | System parts are properly aligned | |||

| 14 | Torque on bolted connections as per manufacturer guidelines | |||

| 15 | Lockout tag-out finished as per guidelines | |||

| 16 | Emergency contact information collected | |||

| 17 | proper isolation from equipment and non-test parts following SOP performed | |||

| 18 | A pressure relief valve installed | |||

| Checklist during Hydrotest | ||||

| 19 | Hydro test equipment properly installed | |||

| 20 | Working professionally with all PPE equipment | |||

| 21 | Pressure is applied gradually following work procedure/standards | |||

| 22 | Pressure maintained for the pre-decided time duration | |||

| 23 | All exposed joints are thoroughly checked for leakage potential. | |||

| Post-Hydrotest Checklist | ||||

| 24 | Repairs started after the release of Hydrotest Pressure. | |||

| 25 | Pressure is released gradually. | |||

| 26 | Water was disposed of as per the procedure | |||

| 27 | Repairs performed following procedures |

Hydrostatic Testing Cost

The cost for hydrostatic testing of piping systems can vary widely depending on a variety of factors, such as the size and complexity of the system, the type of test fluid used, and the location of the system. Other factors that can affect the cost include the need for special equipment, such as pumps and gauges, and the cost of any necessary repairs or maintenance.

In general, the cost of hydrostatic testing can range from a few hundred dollars to several thousand dollars or more. For small, simple systems, the cost may be relatively low, while larger, more complex systems can require more time, labor, and equipment, resulting in higher costs.

To get an accurate estimate of the cost of hydrostatic testing of a specific piping system, it is best to contact a qualified testing contractor or service provider and request a quote based on the specific details of the system in question.

Difference between Hydro Test and Hydrostatic Test

Hydrotest and hydrostatic tests are often used interchangeably to refer to the same testing process, which involves filling a piping system or component with a fluid, usually water, and subjecting it to pressure to check for leaks or weaknesses.

Part C: Pneumatic Test in Piping

What is the Pneumatic Test?

The pneumatic test is a type of pressure test for checking system integrity under pressurized conditions and is applied to systems where the hydrostatic test is difficult to apply. A pneumatic test uses clean, dry, and oil-free air, nitrogen, or any non-flammable and non-toxic gas.

How to Calculate Pneumatic Test Pressure? | Pneumatic Test Pressure

The pneumatic test pressure shall be as per the following equation:

Pt=1.1*Pd

Piping Pneumatic Testing Procedure

Pneumatic test for piping is done in three steps: Pressurization, Inspection, and De-pressurization.

To avoid brittle fracture, the pressure shall be increased by less than 10% of test pressure per minute

into the system allowing adequate time for temperature equalization. The pressurization shall follow this sequence:

- Step 1. Gradually increase to 1.5 barg

- Step 2. Hold for 10 minutes;

- Step 3. Perform a preliminary check, including examination of joints by applying soap methods.

- Step 4. If leaks are discovered, release pressure, repair, and return

- Step 5. Gradually increase the pressure in steps of 10% until the test pressure is reached, holding the pressure at each step for sufficient time (minimum 10 minutes) to allow the temperature and strain to stabilize; Observe the pressure gauge for loss of system pressure at every incremental step stage. If pressure loss exceeds 10% of test pressure, the system pressure should be reduced to 1.5 barg and follow steps 3 & step 4.

- Step 6. Hold for 10 minutes at 100% test pressure and Observe the pressure gauge for loss

- Step 7. Depressurization of the system.

The depressurization rate shall be calculated, considering the Joule-Thomson effect, to prevent brittle fracture while the system remains under stress.

Inspection shall only be permitted after the pneumatic test pressure has been achieved, held, and

then reduced to the design pressure

Difficulties with Pneumatic Testing

Pneumatic tests are potentially more dangerous than hydrostatic tests because of the higher level of potential energy stored during compressing of the gas. Care must be exercised to minimize the chance of brittle failure during testing by initially assuring the system is suitable for pneumatic testing.

Pneumatic tests could be performed only when at least one of the following conditions exists:

- When the systems are designed in such a way that they cannot be filled with water.

- When the systems are such that it is to be used in services where traces of the testing medium cannot be tolerated.

Using a pneumatic test instead of hydrostatic requires approval from proper authority or body.

Part D: Difference between Hydrostatic Test and Pneumatic Test

Comparison of Hydrostatic Testing and Pneumatic Testing

The following table lists the major differences between hydrostatic and pneumatic testing.

| Hydrostatic Testing | Pneumatic Testing |

| Hydrostatic test pressure is normally 50% higher (As per ASME B31.3) than the design pressure. | Pneumatic test pressure is normally 10% higher than the design pressure |

| Hydrotest is recommended for high-pressure applications. | A Pneumatic test is recommended only for low-pressure applications. |

| In a hydro test, the test media (Water) used is not compressible by pressure application. | In a pneumatic test, the test media, Air is compressible by pressure application. |

| In hydrostatic testing, the energy stored per unit volume of water under test pressure is negligible. | The energy stored per unit volume of compressed air under test pressure in the case of a pneumatic test is very high. |

| Needs thorough cleaning after the hydrostatic test to eliminate moisture, especially for services that are reactive to moisture/fluids. | Easy to clean after pneumatic testing. |

| Pressure Relief devices are usually recommended to control a sudden increase in pressure during hydro testing. | Pressure relief devices are a must during the pneumatic test to ensure no over-pressurization. |

| Chances of equipment/ Pipe/test apparatus failures are very low during hydro testing. | Chances of equipment/ Pipe/test apparatus failures are high during pneumatic testing. |

| The weight of equipment along with the hydro test medium as water is high hence special attention should be given to the floor and supporting arrangements. | The weight of equipment with the pneumatic test medium as air is comparatively less. |

| Needs verification and examination of joints and connections before testing. | Needs very careful checking of weld joints thoroughly before testing. |

| In hydrostatic testing, the test media can be reused or transferred to other places after testing. | In pneumatic testing, the test media can not be reused or transferred to other places after testing. |

| Skilled and semi-skilled personnel can carry out the test. | Needs the involvement of senior experienced staff to monitor the test. |

| Recommended that large volumes are to be tested at the same time (for example pipelines). | If pipelines are tested should be done with small segmental lengths at a time. |

| Damages made by failures are less compared to failures in pneumatic testing. | Damages made by failures in testing are very huge and extensive as compared to hydrostatic testing. |

| Hydrotest is a regular day-to-day practice and safe procedure and it can be followed in any work site. | Needs special attention and safety precautions for performing a pneumatic test. |

| Pressure changes finite amounts by an infinitesimal change in volume. | The pressure change is proportional to the volume change. |

Frequently Asked Questions | Hydrotest FAQs

What is the difference between the Hydro test and the Hydrostatic test?

Both hydro test and hydrostatic test refer to the same pressure test method. Hence, both are the same and there is no difference between the Hydrotest and Hydrostatic test.

What is the hydro test pressure for the Pipeline?

The hydrostatic test pressure considered for pipeline systems is 1.25 times the design pressure.

How is the Hydrostatic test done?

A Hydrostatic test is done by filling the system with water and then pressurizing it to hydro test pressure (usually 1.5 times of design pressure). The pressurized system is kept for a pre-decided time and then visually all joints are checked for any leakage.

Can a Hydrostatic test cause damage?

Yes, a hydrostatic test can cause damage. Some examples of hydro test hazards are provided here.

What is the safest type of Pressure Testing?

Hydrostatic testing is the safest type of pressure testing as it generates considerably less stored energy which in turn involves less risk to workers.

Is a Hydrostatic test mandatory?

Most of the codes and standards prefer to use hydro testing as the best method for pressure integrity checks. However, in some situations, the hydrostatic test may be avoided. An example is a golded joint.

A golden joint is usually the final joint to weld the new pipe with the existing pipe. As the Hydrostatic test is usually not feasible, NDE (ultrasonic or radiographic test) is performed in place of pressure testing.

How long should a pressure test last?

It depends on various factors like the governing codes, standards, and local procedures; the length of the system, the number of joints to check, etc. Usually, the system should be pressurized for a least 10 minutes.

Which pipes can be excluded from pressure testing?

The pipes that are open to the atmosphere, such as vents or drains downstream of the last shutoff valve, Non-hazardous lines open to the atmosphere, lines connected to silencers, open-ended portions lines, and open funnels do not require pressure testing.

Video Tutorial on Differences between Hydrostatic Test and Pneumatic Test

The following video tutorial explains the major differences between the Hydrostatic test and the Pneumatic test.

Hi,

Thanks for providing valuable information on hydrotest and pneumatic test. One of the questions I had on my current project is that we are buying Stainless Steel inline instruments on Carbon steel lines. Also it is noticed that the hydrotest pressure on such lines is calculated based on corresponding operating pressure for Stainless steel material at that temperature.

My opinion is that by doing so we are derating the hydrotest pressure for carbon steel and are not testing it to the required pressure. Is it ok to do so.

Please provide your feedback.

Regards,

Vinay

Dear sir we need it. how to convert the air testing to water hydrotesting.

No matter wich material is. Remenber that the instruments buyed for opetation or for a test must be designed to resist higher pressueres. For example any elbow or plug you buy must resist 2 times the test pressure as minimun.

Very good and explained.

Thanks.

This is very good article about Hydro Test and Pneumatic test in Piping.

Thanks

Very good article but comparison table shows hydrostatic test = 30% higher than design pressure when it should read 50%

i.e. Pt=1.5*Pd*(St/Sd)

thanks

Where did this 1.3Pd came from?

Piping designed as per B31.3 is never hydro-tested at 1.3times of test pressures,1.3 is for pressure vessels designed on ASME Sec VIII Div 1(UG-99(b) is 1.3 x MAWP at Design Temp. x lowest ratio of S at test temp to S at design temp). However, B31.3 states Pt=1.5*Pd*(St/Sd) for piping.

that’s it.

Very very useful for piping beginners and stress engineers. Its look like a Google for piping learners. Thanks

Very clear. Table is very quick reference.

Hi there,

what will be the load cases we will be using for pressure test in case of FLARE SYSTEM .

Normally Flare lines are not hydrotested.

Check the project document.

If pneumatically tested then separate load case is not required.

If hydrotested then same load case (WW+HP)—HYD need to be prepared what you make for other systems.

Nozzle is getting fail in hydro Case. Almost 15 times the allowable. What could be the reason behind it? Burdon effect is activated.

Hydro Pressure is OK. Thickness of Pipe is OK. Units are OK.

Any other reason ?

Please let me know the reason of multiplying St/Sd.

Please let me know the detail of that equation.

Can you please explain how to calculate the energy stored in piping due to pneumatic pressure?

Very informative article!! Thank you.

Stored energy in a pipe during Pneumatic testing :

The process inside the system is assumed as adiabatic compression.

As per the ideal Gas equation-

PV= mRT

Where

P= Pressure

V= Volume

m= Mass of Gas

R= Gas constant

T=Temperature of the Gas

Work done in an adiabatic compression = mCv DT

= mCv (T2-T1) Constant Volume process

=R/( -1) m (T2-T1)

=R/( -1) mT2( 1-T1/(T2 )) mT2= P2V2/R – Ideal gas equation

=R/( -1) P2V2/R {1-( V2/V1) (-1)}

=R/( -1) P2V2/R {1-( P1/P2) (-1/)} as per adiabatic equation PV = C

= P2V2/(-1) {1-( P1/P2) (-1/)}

Where

P2= Test pressure(abs)….psi

V2=Volume of the pipe (Total Volume under test pressure)….m3

= Ratio of specific heat for the test fluid (gamma)

P1=Abs Atmospheric pressure….psi

This formula is similar to the one given by the ASME standard ASME-PCC-2-2008 regarding the energy calculation in its Article No. -5.1, Mandatory Appendix II.

what is the minimum air pressure test for pipes for bs 1387 pipes

All water piping shall be tested to hydro-static test pressure of at least one and a half times the maximum

operating pressure but not less than 10 kg/sq cm for a period of not less than 24 hours. Why 24 hours is required?

We have situation where a Discharge Pipe for an LPG storage bullet (pressure vessel) is encased (sleeved) inside a larger diameter pipe. The weld joint connecting the discharge line to the bullet is a golden weld (GW). Our project Spec does not allow GW. However this GW is located inside a larger diameter pipe sleeve which is welded to the bullet at one end and to the discharge pipe at the other end. The sleeve pipe can be tested (pneumatically) to the same required test pressure for the Discharge Pipe. My question is as follow: If we pneumatically test the sleeve pipe to the same test pressure of the Discharge Pipe, which in turn will be subjecting the GW joint on the Discharge Pipe to external test pressure, can this be considered a substitute to subjecting the Discharge Pipe GW to internal pneumatic pressure testing? Your reply will be much appreciated.

Can u give some information about pressure relief device that at what pressure and at what pipe dia we should use pressure relief device

Very good article…

Good comparison , While critical line analysis , How Caesar ll Hydro load case look like in case of pnumetic test requirement , please put more light., We generally put same hydro case (Ww+HP)=HYD to see the impact. HP is considered 1.5 times of Pd but WW weight should not come.

@ Vinay Sharma. The hydrotest of the main line which is in Carbon Steel materials should be the basis for your testing. Any components connected to it shall be subjected to the same during operations. However, at cases where there piping component is not designed to be subjected to such pressure, can be dismounted and shall be tested on its own.

@naveed

How can you revalidate/ rerate existing piping system, (esp flare header line for increased load)?

I wish to know. If I test a Valve @ 10Kg/SqCm Hydro Pressure at what pressure should I test the same with Pneumatic Pressure. Is there any formula for applying it and any limitation of Size of the valve.

Please explain me one doubt. This article says, hydrotest is the last physical test. No hot work should be done after that. In case of over head lines, what we need to ensure when hydrotest is done on ground level and then pipe is erected by hot work?

Dear your blog is very interesting and good, that i can’t tell how knowledgable it is. It’s such a rewarding work you had done.

Hi thanks for the great explanation

We are looking to test Rubber Bulk hoses Dia 6″ at WP 10bar

I need to confirm what sort of pressure test should be done i.e. either

1. Hydrostatic (filling the hose with water and then pile up the pressure to WP10bar)

Or

2. Directly fill the hose with air compressor up to WP 10bar?(not filling with water just directly attaching compressor outlet to hose with other end of hose blocked with a dead plate)

Would really appreciate your technical input . Thank you very much

rgds

Very good learning

Very good learning

Comprehensive explanation Hydro test Vs Pneumatic test,

Well explained all key points

Please send me this documents.

Please specify to standard re:

Pt= 1.5 x Pd * (St/ Sd)

The Normal practice is 1.5 x Pd,, is there a standard update on this? If yes, please mention the std and edition.

Thank you.

Thanks for sharing the information.

As Aquilino De Belen says, I also like to know more about and where to get this info (St/Sd).

With a max. of 6.5, Test Pressure is nearly 10 times Design Pressure.

Thank you.

Good work.

Excellent article & very detailed explanation. Probably we can add 1). Pneumatic testing is not applicable for systems that handle hot liquids (as the expansion of piping during the operation will result in leaks and there is no way to identify such leaks during pneumatic test). 2). Water quality used for hydrostatic testing is governed by the maximum allowed Chloride content in case of Stainless steel piping.

Hi Arup,

Greetings from the day!

I have some queries related to pneumatic pressure test of oil pipe line.

Is the any guideline that how much of the pipe line should be emptied before starting the pressure test?

As the test pressure is about 12bar, is there any rule/ guideline to define the pressure rise steps (pressure vs time), as well after the pressure test to remove the pressure?

What is the allowable loss (practicle value) for a pipe line with aroung 30m length and 10 flange connection?

What is allowable pressure loss (as per standard/ guideline)?

Is there any guideline for minimum hold time of presssure for a leakage test?

WBR,

B16.5 specifies hydraulic pressure test @1.5 times operating pressure rounded to 1 bar, for a duration of 60 seconds for fittings below 2″ NB.

While testing liquid level gauges ( Small internal volume), the instrument is pressurized slightly MORE than 1.5, so that it would remain above specified TP.

During the inspection of joints for leakage, the Pressure Gauge would show SMALL DROP ( say 62 bar to 60 bar for Test Pressure of 58 bar) due to cumulative small leakage thru multiple joints of the test set up, NRV/Drain Valve and test hose joints, etc.

Despite the drop, Pressure remains ABOVE TEST PRESSURE throughout the duration of the inspection. NO LEAKAGES are observed from any of the joints. Should the instrument be rejected …just for the negligible pressure drop in the range above TP of 58 bar?

Hii

Thanks for this blog

It has basic but important information about pressure testing.

Please write a blog on how to decide hydro pressure testing gauge while test .

Why test gauge should have higher pressure range than actual test pressure ?

I can see how a business could really benefit from getting the right test for their pipes in order to make them more effective.

I’m working on updating our pressure testing procedure and would like to add information on the types of systems listed below. Some of the information I’m looking for is Degrees in Fahrenheit that each material becomes brittle (Ductile-brittle transition temperature), pressure relief device requirements, Pneumatic & hydrostatic testing pressures, pneumatic & hydrostatic testing procedures, preliminary pressure test requirements. Thanks in advance for your help!

• Fiberglass piping systems;

• Plastic piping systems;

• PVC piping systems;

• CPVC piping systems;

There is no clarity for correction to be given in hydro test pressure for higher operating temperatures. This correction is must. Please refer ASME code of Indian Standards for correction requirement for temperature

This is also applicable for pressure vessels.

If vessels are located at 15 m or higher elevation vessel elevation can be subtracted from design pressure. When MoC is SS 316 or 316 Ti or 316 L, this will help to reduce vessel thickness and save cost for those cases where calculation are on border line and one goes for next higher thickness

I have saved cost of project based on above

D M Butala

Techint Consulting Engineers

ChemiePro Tech Consultancy

What is the standard and procedure for pressure testing Refinery Instrument air line

A process line is assembled using flanged spools that were fabricated and successfully hydrotested in the remote shop thus demonstrating integrity of all welds and piping components. No field welds are used to connect the spools, just flanges. Is field hydrotesting of the assembled line still required? Or perhaps a leak test using helium or N2 is sufficient to detect any gasketed joint leaks ?

A good and comprehensive article on the pressure test.

You may consider adding/addressing the following:

(a) The core objectives of the pressure test are to assure the Integrity of all the weld joints on the system being subjected to pressure test (b) Identify visual leaks of the test medium from the piping system (c) Witness and record the Rate of acceptable pressure drop in blocked-in condition, if the presence or absence of the visual leaks can not be vouched for (d) if a pipe piece has been hydrotested on grade individually and later on connected with the other pipe (also Individually hydrotested) by a flanged joint, the combined system would have to be tested only for tightness test, at a much lower pressure say 2 barg. It need not be pressurized up-to normal operating pressure of much higher values at the time of test. (e) Explain the significance, relationship and understanding of the terms operating pressure, design pressure and working pressure. Few non mechanical engineers may face hard time differentiating between maximum operating pressure and maximum allowed working pressure. (f) The pressure test of pressure vessels and columns having internals need to follow a different strategy. (g) Please also briefly touch the subject of testing of the Atmospheric storage tanks and process systems/piping/equipment operating udder vacuum.

Please provide me safe distance formula during hydrostatic test .And provide me pump selection formula.

Can you provide hydrotest safe distance calculation.

There is any alternative for pressure saftey valve in hydrotest. If yes please mention the standard reference

I like how you mentioned the two techniques widely used for testing piping or tools: the pneumatic test and hydrostatic test.

pneumatic test substitution Hydrotest factor for pressure Equivalent.

If someone need to adopt 100% radiography in lieu of the hydrotest. Then what type of challenges faced by piping system?