Wastewater treatment is a process to treat sewage or wastewater to remove suspended solid contaminants and convert them into effluent that can be discharged back to the environment with acceptable impact. The plants where the wastewater treatment process takes place are popularly known as Wastewater treatment plants, Water resource recovery facilities, or Sewage Treatment Plants. Pollutants present in wastewater can negatively impact the environment and human health. So, these must be removed, broken down, or converted during the treatment process. Typical pollutants that are normally present in wastewater are:

- Bacteria, viruses, and disease-causing pathogens.

- helminths (intestinal worms and worm-like parasites)

- Toxic Chlorine compounds and inorganic chloramines.

- Metals possessing toxic effects like mercury, lead, cadmium, chromium, and arsenic.

- Decaying organic matter and debris.

- oils and greases.

- Toxic chemicals like PCBs, PAHs, dioxins, furans, pesticides, phenols, etc.

- Some pharmaceutical and personal care products.

How is wastewater formed?

A number of activities help in the formation of wastewater. Domestic wastewater is generated because of activities like bathing, washing, using the toilet, etc in residences, restaurants, and businesses. Surface rainwater runoff is generated due to the mixing of debris, grit, nutrients, and various chemicals. Industrial wastewater results because of chemical and manufacturing industry discharges. So, wastewater is essentially the used water that has been affected by domestic, commercial, or industrial use.

Domestic wastewater is relatively easy to treat as compared to industrial wastewater due to its high-strength nature.

Wastewater Treatment Process

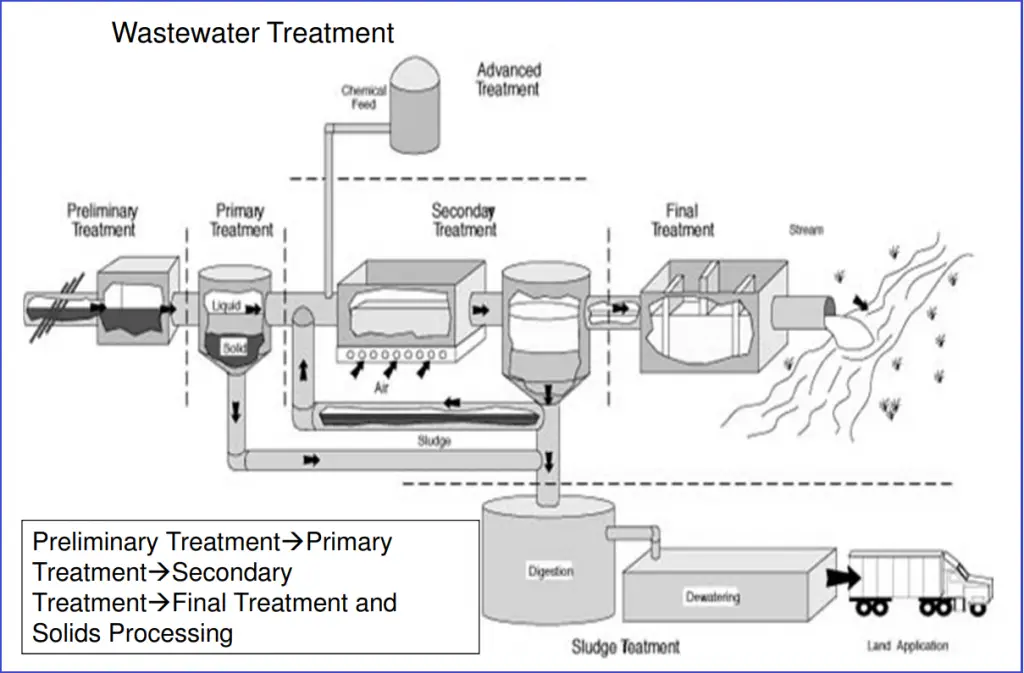

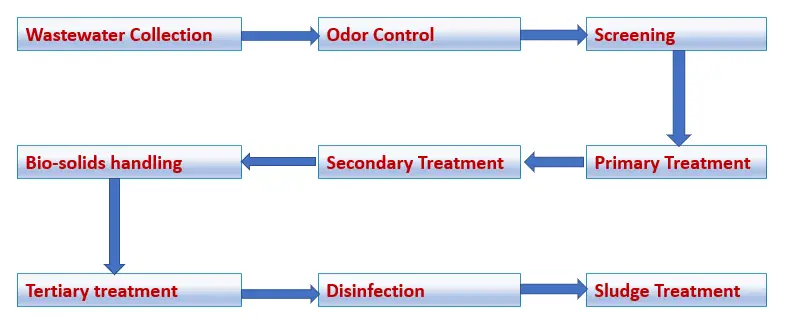

The sequence of wastewater treatment processes is usually characterized as:

- Preliminary treatment

- Primary treatment

- Secondary treatment

- Tertiary treatment or Advanced treatment

Preliminary treatment:

Preliminary wastewater treatment precedes primary treatment. Its main function is to minimize operational problems and to protect subsequent treatment units. The major processes that are used during the preliminary wastewater treatment process are Equalization, Neutralization, Temperature adjustment, Screening, Grit removal, etc.

Primary treatment:

The primary wastewater treatment process is the physical or chemical treatment for the removal of materials that will either float or readily settle out by gravity. The major processes used in this step are Sedimentation and Dissolved air floatation. Suspended solid materials from the wastewater are removed by the sedimentation primary treatment. Other floatable materials like oils, fats, etc are removed using dissolved air floatation treatment. Primary wastewater treatment, in general, removes about 60% of suspended solids from wastewater.

Secondary treatment:

Secondary wastewater treatment uses biological and chemical means for the substantial elimination of dissolved organics and colloidal materials. The processes used in the secondary treatment are Activated sludge, Aerated Pond, Aerobic-anaerobic ponds, Trickling filter, Chemical oxidation, Chemical mixing flocculation and clarification, Gravity filtration, Dissolved-air flotation with chemicals, Pressure filtration, Anaerobic contact, etc. Secondary wastewater treatment is capable of removing more than 90 percent of suspended solids.

Advanced treatment:

Advanced wastewater treatment is used to remove pollutants by methods other than those used in conventional treatment methods mentioned above. The advanced wastewater treatment process employs a number of different unit operations like Activated carbon adsorption, Micro straining filtration, ponds, post-aeration, Land treatment, membrane solids separation, and specific treatment processes such as phosphorus and nitrogen removal, etc.

Very high effectiveness is the characteristic of the Advanced wastewater treatment process. That’s why this method is employed to meet strict effluent standards. For example, Phosphorus levels of less than 1 milligram per liter and total nitrogen levels of 5.0 milligrams per liter or less can be maintained through an advanced wastewater treatment process.

Basic Design Considerations

Wastewater Treatment Requirement: The requirement of wastewater treatment is dependent on the following parameters:

- the influent characteristics,

- the effluent quality requirements, and

- the wastewater treatment processes that produce an acceptable effluent.

Laboratory tests of wastewater samples are performed to find out influent characteristics. Effluent quality requirements are fixed by Federal, interstate, State, and other local regulatory agencies. Wastewater Treatment processes are then decided according to influent-effluent constraints and economic and technical considerations.

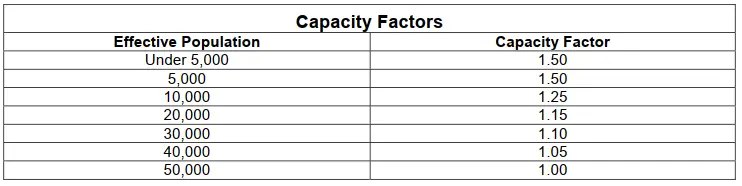

The Capacity of Wastewater Treatment: The capacity of wastewater treatment is decided based on the design population and multiplying it with the proper capacity factor. Design population is found by adding total residents with 1/3 the non-resident populations. The following image (Fig. 2) provides a sample table of capacity factors with respect to effective population.

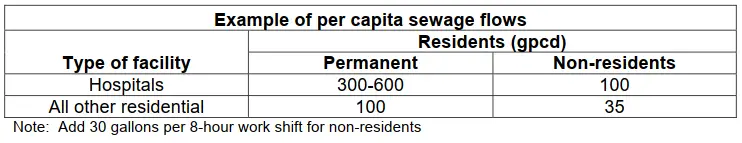

Future service demand calculation: Per capita waste loads of a community are decided based on the nature of the activities as different activities have different water uses. The table in Fig. 3 provides a typical example of sewage flows in gallons per capita per day (gpcd).

Estimating the volume of wastewater:

The required average daily wastewater flow for the design of new wastewater treatment plants needs to be calculated by multiplying the design population by the per capita rates of flow as determined from the table in Fig. 3.

To calculate contributing populations, a factor of 3.6 persons per family residential unit can be considered. For hospitals, the calculation can be done by counting the number of beds, plus the number of hospital staff eating three meals at the hospital, plus the number of shift employees having one meal there. This total is the number of residents to be used in the design calculations. The capacity factor still needs to be applied while calculating design populations.

To find the volume of industrial flow, actual measurements can be done to ascertain the flow rates. Typical industrial discharges include wastewater from the following:

- wastewater treatment plant itself;

- vehicle wash areas;

- maintenance facilities;

- swimming pool backwash water;

- weapons cleaning buildings;

- boiler blowdowns;

- photographic laboratory;

- water treatment plant backwash;

- cooling tower blowdown;

- fire fighting facility;

- medical or dental laboratories.

When significant inflow enters the sewer system, storm-water flows should be included in wastewater treatment plant design.

Once, all the above data is calculated, the following equation is used to estimate the total anticipated flow to the sewage plant:

x = a + b

Where

x = Total flow to sewage plant

a = Flow from population (effective population × 100 gpcd × capacity factor)

b = Infiltration + industrial wastewater + storm-water (4 × dry-weather flow)

The following image (Fig. 4) provides a typical flowchart for Wastewater treatment processes.

Types of Wastewater Treatment Plants

For the betterment of society, the environment, and the future, wastewater treatment should be taken seriously. The outbreak of numerous waterborne diseases can be prevented by proper wastewater treatment. So, Wastewater treatment plants play a major role in keeping the environment clean and saving numerous lives. There are basically three types of Wastewater treatment plants:

- Effluent Treatment Plants

- Sewage Treatment Plants, and

- Combined Effluent Treatment Plants

Effluent Treatment Plants are used by major chemical, leather, and pharmaceutical companies to purify water and remove dirt, grit, pollution, toxic, and non-toxic materials, polymers, etc. The typical processes used by Effluent Treatment Plants are centrifuging, filtration, incineration for chemical processing, and effluent treatment.

Sewage treatment plants eliminate contaminants from wastewater and household sewage. It uses physical, chemical, and biological processes to remove physical, chemical, and biological contaminants to make water and solid waste reusable.

Combined Effluent Treatment Plants are established where a cluster of small-scale industries is present. Such facilities reduce the cost of a single company while preventing pollution.

Top Online Courses on Wastewater Treatment

Wish to know more about waste-water treatment! Then the following video courses are for you. Click on the subject below and review the details and then proceed to take the course.

- Membrane Technology for Water and Wastewater Treatment

- Water Treatment Process Design

- Membrane Technologies Used in Water and Wastewater treatment

- Basics of Water Desalination Technology

- Water Treatment for Beginners

- Design of Sewage Treatment Plant (STP)

- Recent Advances in Water Treatment -for developing countries