HDPE pipe is a flexible plastic pipe made of thermoplastic high-density polyethylene widely used for low-temperature fluid and gas transfer. In recent times, HDPE pipes got their extensive uses for carrying potable water, hazardous wastes, various gases, slurry, firewater, stormwater, etc. The strong molecular bond of HDPE pipe materials helps it to use for high-pressure pipelines. Polyethylene pipes have a long and distinguished service history for gas, oil, mining, water, and other industries. Due to its low weight and high corrosion resistance, the HDPE pipe industry is growing tremendously. In the year 1953, Karl Ziegler and Erhard Holzkamp discovered high-density polyethylene (HDPE). HDPE pipes can work satisfactorily in a wide temperature range of -2200 F to +1800 F. However, the use of HDPE Pipes is not suggested when the fluid temperature exceeds 1220 F (500 C).

HDPE pipes are made by the polymerization of ethylene, a by-product of oil. Various additives (stabilizers, fillers, plasticizers, softeners, lubricants, colorants, flame retardants, blowing agents, crosslinking agents, ultraviolet degradable additives, etc.) are added to produce the final HDPE pipe and components. HDPE pipe lengths are made by heating the HDPE resin. It is then extruded through a die, which determines the diameter of the pipeline. The Pipe wall thickness is determined by a combination of the die size, the speed of the screw, and the speed of the haul-off tractor. Usually, 3-5% carbon black is added to HDPE to make it UV resistant, which turns HDPE pipes black in color. Other color variants are available but usually not used frequently. Colored or striped HDPE pipe is usually 90-95% black material, where a colored stripe is provided on 5% of the outside surface.

Properties of HDPE Pipes

The physical and mechanical properties of a typical HDPE Pipe are listed below:

- Governing Codes: ISO 1183, ISO 4427, AS/ NZS 4130, BS EN 12201, EN 12056, AWWA C901, AWWA C906, etc

- Available size range: DN 16 to 1600 (However, other customized sizes can be manufactured)

- The density of HDPE Pipe: 930-970 kg/m3

- Typical Mechanical Properties of HDPE Pipe are given in Table 1 below. However, these values vary from one manufacturer to another. So, must be consulted with the manufacturer.

| Mechanical Properties | HDPE Properties |

| Yield Strength | 18-26 Mpa |

| Elongation | 10% |

| Elastic Modulus | 900 Mpa |

| Hardness | 61 Rockwell (Shore) |

| Poisson’s Ratio | 0.45 |

| Linear Coefficient of thermal expansion | 0.17 mm/m-0C |

| Brittleness temperature | <-700C |

Types of HDPE Pipes

Depending on maximum pressure withstanding capability, HDPE Pipes are classified into several pressure grades known as PN grades. They are

- PN 2.5 – max pressure 2.5 bar

- PN 4 – max pressure 4 bar

- PN 6 – max pressure 6 bar

- PN 10 – max pressure 10 bar

- PN 16 – max pressure 16 bar

- PN 20 – max pressure 20 bar

- PN 25 – max pressure 25 bar

Again, based on the types of materials used HDPE pipes are grouped into the following types:

- PE 63 – medium pressure piping systems

- PE 80 – gas pipe for natural gas distribution network with pressure rate up to 4 bars or drinking water pipe with pressure rate up to 16 bar – sewers, outfall pipes, industrial pipes

- PE 100 – high demands piping applications

The numbers following PE indicate the minimum required strength in Bar at 200 C for 50 years life span corresponding to ISO-4427. The rated working pressure of HDPE pipes is determined at 200 C. For higher temperatures, a derating factor (Table 2 Below) is used to determine the maximum pressure to which the HDPE Pipe can be subjected.

| Fluid Temperature (0C) | Temperature Derating factor |

| 0-20 | 1 |

| >20-25 | 0.9 |

| >25-30 | 0.8 |

| >30-35 | 0.7 |

| >35-40 | 0.6 |

| >40-45 | 0.5 |

| >45-50 | 0.4 |

Length of HDPE Pipes

As HDPE Pipe manufacturing is a continuous process, pipes of any length can be manufactured. However, due to transportation requirements and ease of handling at the site, the HDPE pipe length is limited and normally produced in standard lengths of 6, 10, 12, 15, 24, and 30 meters. HDPE Pipe lengths of 50 and 100 meters can be produced on request.

Joining HDPE Pipes

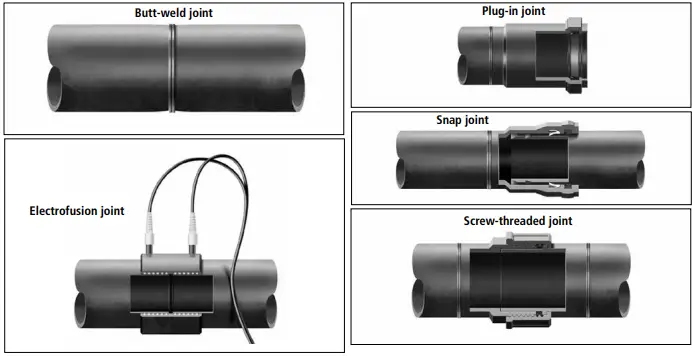

HDPE Pipes and fittings are joined to each other by Welding or by mechanical fittings. There are two types of welding methods used to join HDPE pipes. They are

- Electrofusion Welding: Electrofusion is a simple and quick method to permanently join individual pipes and HDPE fittings or prefabricated sections in tight places. This method is suitable for on-site joints.

- Butt Welding: Butt-welding homogenously joins HDPE pipes and fittings into prefabricated sections using heat and pressure without using additional connection fittings.

Various types of mechanical joints can be used for joining HDPE pipes to HDPE or dissimilar pipes. They are

- Plug-in joint

- Snap joint

- Screw-thread joint

- Flanged joint

- Contraction sleeve

- Sleeve coupling

- Metal coupling

- Rubber collar joint

Fittings for HDPE Pipes

A complete range of HDPE Pipe fittings is available for any purpose. Typical HDPE pipe fittings include:

- Bends

- Elbows

- Reducers

- Branches

- End caps

- Electrofusion couplers

- Mechanical connection fittings

- Traps

- Sanitary fittings

- Spare parts

Design Criteria for Aboveground HDPE Pipe

Factors that can influence the behavior and thus, the design of above-ground HDPE piping systems are

- Temperature: For pressure systems, the use of HDPE pipes is usually limited to -400C to 500 C. For non-pressure services, higher temperatures can be used. Consult with the manufacturer for getting information about their product. Note that, the coefficient of linear thermal expansion for HDPE pipes is approximately 10 times higher than that of metal pipes. So, the potential of thermal expansion due to temperature fluctuations is very high and must be considered in the design. A typical Thumb rule is HDPE pipes will expand or contract by 0.2mm per meter per °C increase or decrease in temperature.

- Internal Pressure

- Chemical exposure

- Potential mechanical impact or loading: Extra protection must be given if the HDPE pipe is installed in a region of high traffic or mechanical abuse.

- Ultraviolet radiation: To safeguard against ultraviolet radiation effects, black HDPE pipes containing a minimum of 2% carbon black are selected.

Pressure Consideration for HDPE Pipes

A number of variables determine the hydrostatic pressure capacity of HDPE pipes. Those are

- Standard Dimension Ratio or SDR is defined as the ratio between the outside HDPE Pipe diameter and the wall thickness.

- The hydrostatic design stress of the HDPE material being used (PE63, PE 80, PE100) for HDPE Pipe Manufacturing.

- The maximum and minimum operating temperatures.

- The duration and variability of the stress applied by the internal hydrostatic pressure during hydrostatic testing.

- The chemical resistance of the HDPE pipe for the service chemical (the standard pressure rating is based on a pipe carrying water).

Usually, HDPE pipe can withstand short-term hydrostatic water pressures that are considerably higher than the pressure rating, or class. But the duty of the HDPE pipe should always be determined following the pipe’s long-term strength at 20°C to ensure a design life of at least 50 years.

Barlow’s Formula is also applicable for HDPE piping that is related to the internal pressure, pipe outer diameter, wall thickness, and circumferential hoop stress and is given by

p = 2 x t x σ /d or alternatively t = p x d/(2.σ + p)

Here:

- p = internal pressure (MPa)

- t = minimum wall thickness (mm)

- d = mean outside diameter (mm)

- σ = circumferential hoop stress (MPa)

The design hoop stresses for HDPE pipe materials are considered as follows as given in ISO 4427:

- PE 63: 5 MPa

- PE 80: 6.3 MPa

- PE100: 8 MPa

Advantages of HDPE Pipes

HDPE pipes provide various advantages with respect to other piping materials like

- Cost-effective. Hence, easily affordable

- High flow rate due to the smooth inner surface

- Wide temperature range

- Non-leaching

- Easy transportation due to low-weight

- UV-resistant

- Amazing Durability (More than 50 years)

- Resistant to most chemical solvents

- Stiff material

- Environment friendly

- Lower maintenance cost

- High Quality

- Reduced installation cost

- Due to its flexible shape, simple to use on slopes.

- Simple joining methods.

- Not affected by underground movements (Seismic Resistant)

- Bad conductor of electricity.

- low-friction

- Ability to dampen water-shock

- Sun-resistant

- Non-stick surface.

- Leak-free due to its seamless nature.

- Prefabricated HDPE pipe sections can be easily installed

Disadvantages of HDPE Pipes

The main disadvantage of HDPE pipes are

- Poor weathering resistance

- Highly Flammable

- Sensitive to stress cracking

- Difficult to bond

- Poor High-Temperature capability

- High thermal expansion

HDPE Pipe Frequently Asked Questions

What is the full meaning of HDPE pipe?

The full form of HDPE is High-Density Polyethylene. This hydrocarbon polymer is produced from petroleum by a catalytic process. Famous for its tensile strength in a similar product category, High-Density Poly Ethylene is a kind of thermoplastic.

Is HDPE the same as PVC?

Both HDPE and PVC are considered plastics. However, they are not the same. HDPE is a thermoplastic made from petroleum and PVC is a durable vinyl polymer. While comparing HDPE and PVC, HDPE due to its flexibility, high strength-to-density ratio, no corrosion, and chemical stability is a strong choice for low-pressure and low-temperature applications.

What is HDPE piping used for?

HDPE or High-density polyethylene pipe is widely used to carry potable water, slurries, wastewater, chemicals, hazardous wastes, and compressed gases. They have been used in various industries like gas, oil, mining, water, and other industries.

How long will HDPE pipe last?

Properly designed HDPE piping systems provide a long-lasting performance as compared to other piping systems. As per the estimates of the Plastic Pipe Institute, they are supposed to last 50 to 100 years.

Is HDPE pipe safe for drinking water?

Yes, HDPE is totally safe for carrying drinking water. This is one of the main reasons that in the water industry and desalination plants, high-density polyethylene pipes are widely used. The application of HDPE pipes for potable water applications is certified by NSF. Various disinfectants like chlorine and chloramine are approved for use in HDPE pipes.

Which is stronger PVC or HDPE?

PVC is stronger and stiffer as compared to HDPE.