What is Pressure Surge or Water Hammer?

A pressure surge is a pressure wave that is caused by the kinetic energy of the moving fluid when there is a sudden change in flow velocity. Due to the instantaneous conversion of momentum to pressure when flowing liquid stopped quickly this sudden increase or surge of pressure is experienced. Pressure surge is popularly known as Water Hammer, Fluid Hammer, or Hydraulic Surge.

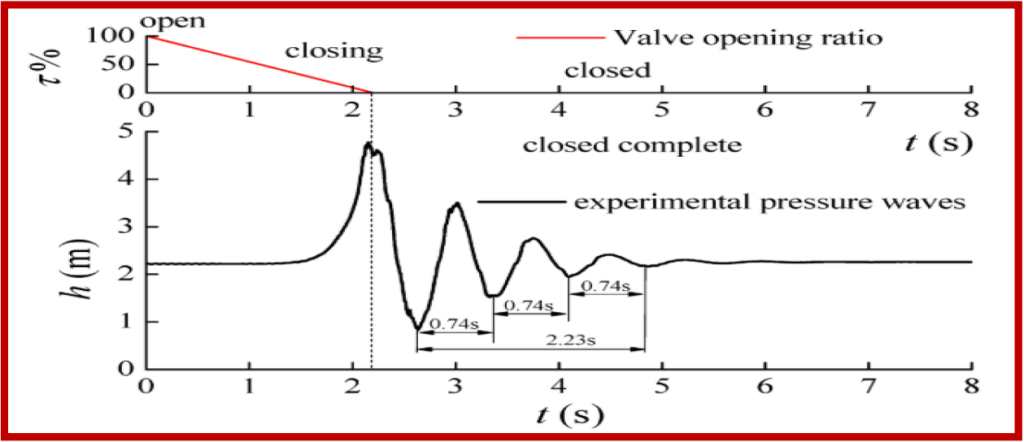

In Piping/Pipeline system networks this phenomenon is a major concern for Piping/Pipeline/Process engineers. As noticed in the below graph (Fig. 1), the pressure spike will continue hitting the pipe/pipeline trying to release the generated excessive energy and therefore the system will be at high risk.

ASME B31.3 defines that the pressure rise due to pressure surge and other normal operation variations shall not exceed the internal design pressure at any point in the piping system and equipment by more than 33%.

What Can Cause Pressure Surge?

Pressure Surge or the sudden change in velocity and or pressure can arise due to various reasons. Hydraulic transients occur at changes in flow in piping/pipelines and this could be due to the:

- Pump start & stop, specifically due to load shedding or sudden power failure

- Quick operation of Valve (Sudden closure/opening)

- Sudden closure of the check valve

- Presence of Air pockets inside piping/ pipeline systems, especially during pump start

- A sudden release of Air

- Quick Pipeline filling

- Pressure Surges can occur in open channels and partly liquid-filled pipes, as well

All of the above causes will generate high-pressure waves that can travel both upstream and downstream from point of origin. Please note that

- Some pipelines are in transient operations over 75% of the time.

- Pressure Surge (pressure rise) increases as the pipeline straight length increases since the contained momentum within two direction changes (elbows/Tee) will be higher (more volume).

- A pressure surge normally consists of multiple events, resulting in up to ten times the normal pipeline pressure. When a surge relief valve opens, it vents the pressure to a safety system.

- Surge pressure is created during the last 20% of valve closure.

Is Water Hammer Dangerous?

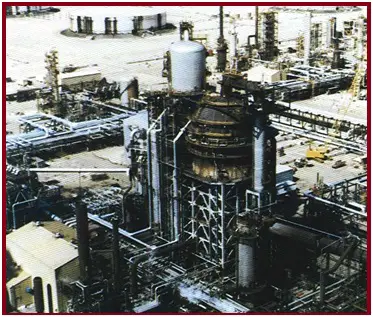

Refer to Fig. 2 to understand what a pressure surge can cause to a Piping System. Pressure Surge of Significant nature creates high pressure and velocity rise that can lead to:

- Failure of pipe/pipeline fittings

- Bursting of pipes

- Damage to the Pump/pumping system

- Deformation of valves and piping supports

- Vibration or shaking of the piping/pipeline system

Basic Definitions concerning Pressure Surge:

- Pressure Surge:– It is basically a pressure wave caused due to a sudden change in flow velocity.

- Wave speed or acoustic velocity:– The velocity at which pressure waves travel through the liquid/fluid.

- Joukowsky equation:– Relationship relating head change to velocity change and acoustic velocity.

- Pipeline Period:– Time required for a pressure wave to traverse the pipe/pipeline length and come back.

- Pressure Head:– Pressure is measured as the height of fluid (10 m head of water is roughly 1 atmosphere)

- Effective Valve closure Time: The period over which a Valve reduces the flow from 90% of its steady state to zero. In relation to Total Valve Closure Time, this is typically the last 15% opening for butterfly valves, 25% opening for ball valves, and 30% opening for plug valves. This can be used as a rule of thumb during the initial assessment phases.

Analysis of Water Hammer/Pressure Surge

The most important parameters to estimate the magnitude of transient pressures is:

- Acoustic wave speed, a

- Pipe/Pipeline period, T

- Joukowsky head, Δh

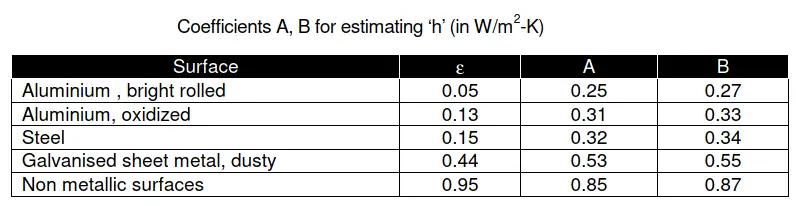

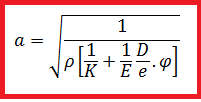

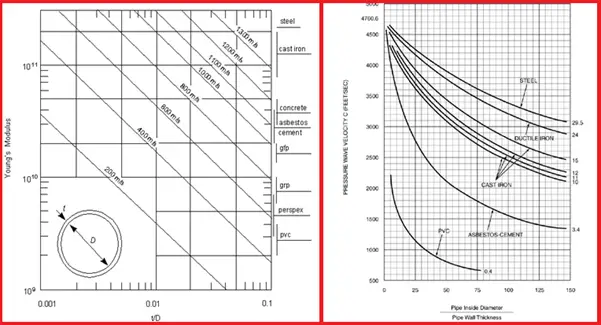

The acoustic wave speed formula depends on the fluid and the pipe characteristics expressed as:

- a = Velocity of the pressure wave

- K = Bulk modulus of the fluid

- ρ = Liquid density

- D = Internal diameter of the pipe

- E = Young’s modulus of the pipe material

- e = Wall thickness

- ϕ = restraint factor (usually taken as 1)

The time that a pressure wave takes to travel from its origin through the system and back to its source is defined as the pipe period. For a single pipeline with pipeline Length, L this is provided as given below:

- T = Critical period

- L = Length of the pipe

- a = Velocity of the pressure wave

Events that take place in less than T are called ‘fast’ events and these are likely to cause pressure surge issues.

As per the Joukowsky formula, the pressure head change (Δh) due to an instantaneous velocity change (ΔV) is expressed as shown above. Here,

- Δh = head rise

- ΔV = change in velocity

- a = wave speed

- g = acceleration due to gravity

This is a very useful guide that explains the likely severity of a pressure surge event but is not a replacement for a proper surge analysis!

Limitations of the Joukowsky formula

Joukowsky formula is applicable to a limited set of fluid systems.

- Its application should be limited to situations matching the following criteria:

- Simple ‘linear’ piping systems i.e. there are no branches by which pressure waves can be reflected back and cause constructive interference in the main line.

- Valve closure time is significantly shorter than the pressure wave communication time.

- System frictional losses are similar to that of a water transport system.

- Joukowsky equation does not consider column separation in its analysis of fluid hammer. Column separation can often result in surge pressures exceeding those predicted by the Joukowsky equation and therefore the Joukowsky equation should not be applied when analyzing a system in which the pipeline pressure can rapidly drop below the fluid vapor pressure.

How to Avoid Pressure Surge

To avoid pressure surge system must be protected. Protection of systems against water hammer can be parted into three groups:

1.0: System Design Solutions:

- Use of pipework with a higher pressure rating i.e to make the pipework stronger to withstand the effects of surge pressure (Normally followed for radioactive, highly corrosive, or lethal fluids, where no fluid is allowed to escape.)

- Rerouting of the pipeline avoiding high/low points

- Changing of piping material, thus altering the wave speed

- Increase the pipe diameter, thereby reducing the velocity

- Increase pump inertia by incorporating a flywheel

- Adding bypass lines

- Providing Additional Pipe supports: By adding more supports in the piping system, the natural frequency of the system is increased. So, vibration tendency will reduce. Also, providing support near concentrated mass will reduce high local stresses.

2.0 Active Protection:

Piping/Pipeline systems can be protected against Surge impact by using devices during pipeline normal operation like:

- Variable speed pumping: Variable speed drives provide a reliable means of preventing damage from pressure surge events.

- Soft starters: The primary purpose of Soft starters is to reduce the electrical load on the power supply to a facility.

- Slow closing and opening valves: A common form of pressure surge initiation is due to the rapid closing of a valve. Extending the closure times attenuates the pressure surge possibility.

Be informed that these devices require power and during load shedding or power failure cannot be of use.

3.0: Passive Protection (Fig. 5):

There are several passive protection equipments available in the market that operates without the need for additional power. A few examples of these are:

- Surge Vessels

- Surge Shafts

- Air Valves

- Vacuum Breakers

- Pressure Relief Valves/Surge relief Valve: Click here to know more about Surge relief valves

- Surge Anticipation Valves: A surge anticipation valve is specially designed to provide a diversionary fluid flow during a pressure surge event.

- Intermediate Check valves: In a long pipeline, an intermediate check valve has the ability to prevent the damaging reverse velocity from reaching a pump station. It effectively reduces the pressure surge to half.

- Gas Accumulators: The gas accumulator is particularly effective in pressure surge scenarios due to a loss of power situation when downstream of the pump check valve, a negative pressure wave develops immediately. The deceleration of the liquid column is reduced by the residual pressure in the gas accumulator and prevents column separation. However, the gas accumulator should be located close to the boundary element that causes the transient event.

- Liquid Accumulators: A liquid accumulator is a vessel that has lower elasticity than the pipe itself. The vessel will exhibit strain to a higher degree than the pipe and thus mitigate pressure transient.

- Using low-modulus thermoplastic materials in combination with ferrous materials can mitigate a pressure surge.

Selection of System for Surge Protection

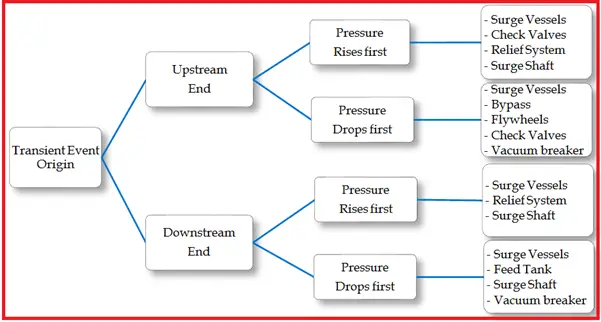

Refer to Fig. 6 below which provide a flowchart for Surge Protection System Selection.

Pressure Surge Modelling Software

There are currently various software packages that can be used for analysis:

- HyTran

- Flowmaster

- WANDA

- Hammer

- AFT Impulse

- PIPENET

- PTRAN

- PASS/Hydro system

- Flownex Simulation Environment

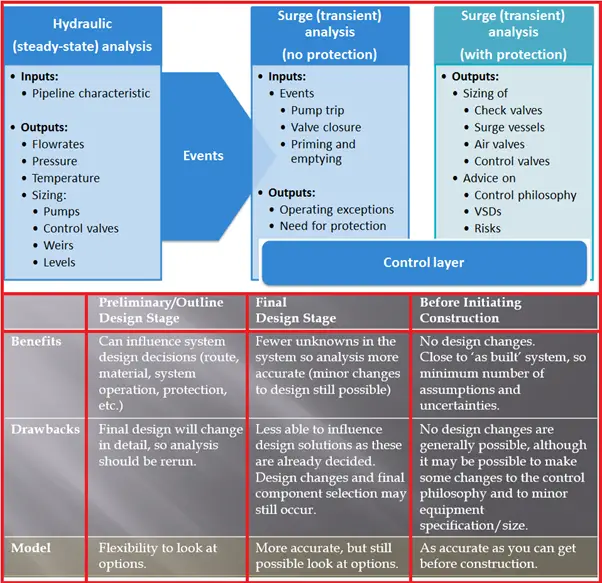

Methodology (Fig. 7):

Designing a Pressure Surge Relief System

- Consideration of a complex range of factors like the potential for pressure increases, the volumes to be passed by the surge relief equipment in operation, and the capacity of the system to contain pressures, etc are required for the design of a complete surge relief system.

- Control or ESD valve closure times can also affect surge pressures in a pipeline. By increasing the valve closure time, a gradual flow decay can be achieved which will reduce the potential for pressure surge.

- Control narrative and system interlocks to ensure Staged pump shutdown sequence and linked ship/shore ESDs when your facility is linked to loading berths/jetties.

- Carry out transient / surge analysis using detailed computer modeling using the software mentioned above to simulate the complex interactions of equipment, pipelines, and fluid to normal, fault, and emergency events.

- Design piping to withstand maximum surge pressure – MSP.

- Although many design approaches can help reduce surge pressures in pipelines, going for a higher pipe rating or massive support arrangements aren’t recommended for the associated significant cost, and a surge relief valve was found to be the most feasible option to protect the system.

- A correctly designed surge relief system will include components to dampen or slow the relief valve on closing, and this often requires sophisticated reverse flow plots.

- In nitrogen-loaded Surge Relief valves, attention must be paid to the nitrogen gas system. The nitrogen system must supply a constant pressure (set point) to the modulating valve, even under conditions of varying ambient temperatures. Normally, the system is designed to use standard gas bottles and has its own control system to regulate the nitrogen supply pressure.

Conclusions:

- The Pressure Surge phenomena during transient events are very important as they can put the system’s integrity at high risk.

- During risk and HAZOP analysis, Pressure Surge Events and the corresponding mitigation devices should be always taken into account.

- System operations staff must be trained in order to prevent operations likely to damage the system’s integrity.

- Surge protection equipment must be maintained periodically.

- It is highly possible to increase the reliability and life expectancy of systems by taking preventive measures for reducing the risk of failure due to pressure surge events,

- The pipe/Pipeline system should be properly supported with the hold downs, guides, and line stops and the supports along with supporting structures must be designed considering dynamic forces during a Surge event.

Some more Resources for you..

Understanding Centrifugal Compressor Surge and Control

Water Hammer Basics in Pumps

Pipe Stress Analysis from Water Hammer Loads

References:

Frequently Asked Questions

Pressure Surge is a pressure wave that is caused by the kinetic energy of the moving fluid when there is a sudden change in flow velocity.

If the high-velocity flow in a pipe is forced to stop or change direction suddenly, a pressure wave generates and moves back at the speed of sound in the liquid. This can produce huge forces in the piping or pipeline system. This is called Pressure Surge in Piping

Pressure Surge, Water Hammer, Fluid Hammer or Hydraulic Surge, all these refer to the same event. There is no difference.

The Pressure Surge in a Piping system can be caused by any of the following Events:

1. Pump start & stop, specifically due to load shedding or sudden power failure

2. Quick operation of Valve (Sudden closure/opening)

3. Sudden closure of the check valve

4. Presence of Air pockets inside piping/ pipeline systems, especially during pump start

5. A sudden release of Air

6. Quick Pipeline filling

Pressure Surge can be avoided by the following methods:

1. Rapid Changes in fluid velocity occurs when valves are opened or closed suddenly. So by reducing the fluid velocity or by increasing the time taken for closing/opening the valve it can be avoided.

2. Surge can be avoided by installing Surge Relief Valve, Surge Tank, Viscous Damper, etc in the system.

3. The impact of surge can be reduced by reducing the number of elbows.

4. Eliminate the Presence of Air

Surge Analysis is the analysis of pressure changes in the piping system, normally performed by Process Engineers for proper pipe sizing or finding the peak surge pressure.