A plug valve is a quarter-turn rotary motion manual valve. It uses a cylindrical or tapered plug (plug-shaped disk) to permit or prevent straight-through flow through the body. Plug valves offer a straightway passage through the ports so that fluid can flow through the opening plug with a minimum of turbulence. Flow can be in either direction fully open or fully closed.

The plug valves have been used in many different fluid services. Their performance is good in slurry applications. They are used in bubble-tight services as an on-off stop valve. They are used in air, gaseous & vapor services, Natural gas & oil piping systems, food-processing, nonabrasive slurry, vacuum, pharmaceutical services, and vacuum to high-pressure applications. They are good for on-off valves, diverting services, and moderate throttling. Initially, Plug valves were designed to replace gate valves as plug valves with their quarter-turn action can easily open and close against the flow as compared to a gate valve.

Plug valves are usually preferred for low-pressure–low-temperature services. Plug valves having body lining with materials like polytetrafluoroethylene (PTFE) can be used for corrosive chemical services.

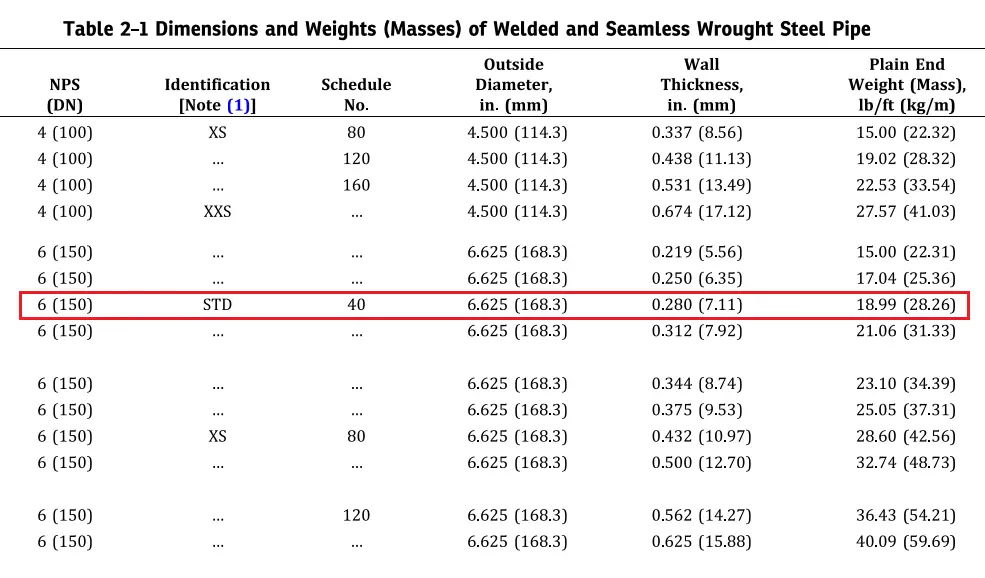

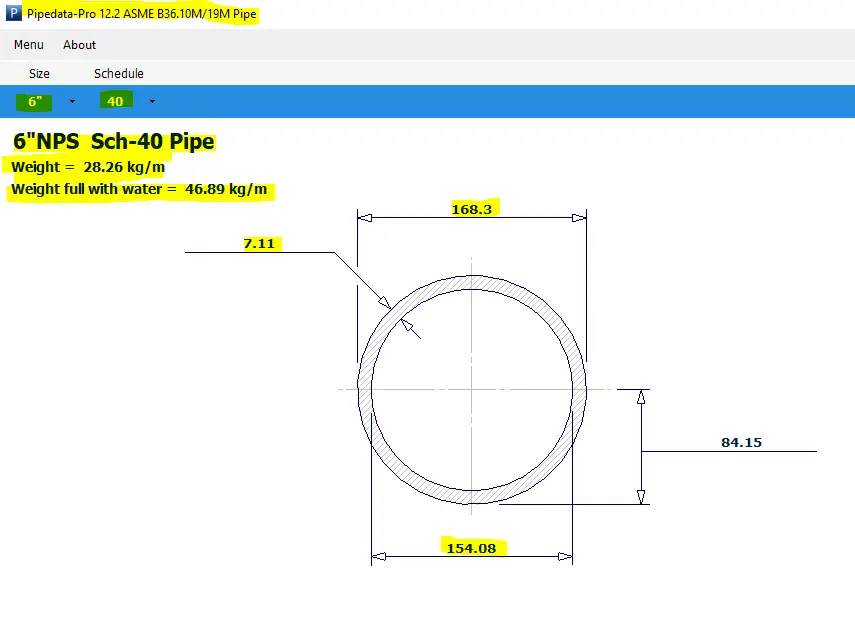

To handle abrasive and sticky fluids, special designs are required. Plug valves are usually found in sizes up to 18 in (DN 450) and in the lower-pressure classes [ANSI Classes 150 and 300 (PN 16 and 40)]. In this article, we will explore the parts, working principles, types, symbols, advantages, and disadvantages of Plug Valves.

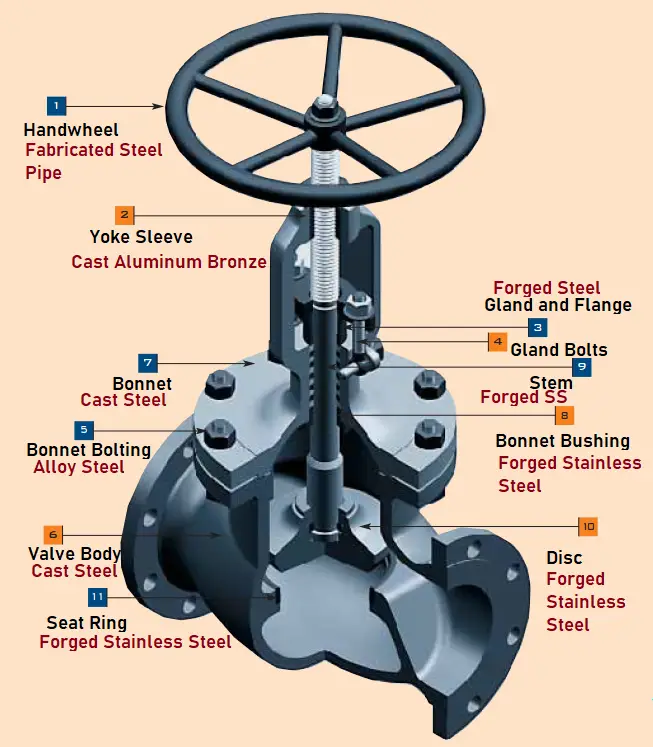

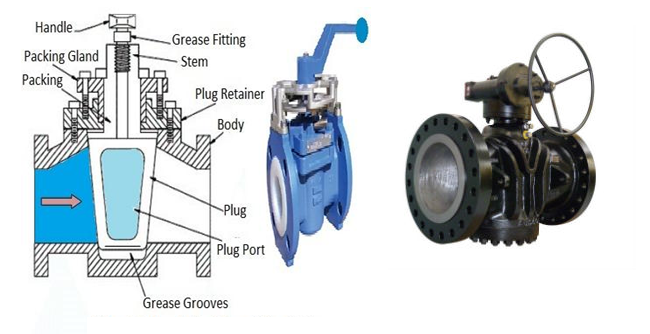

Components of a Plug Valve

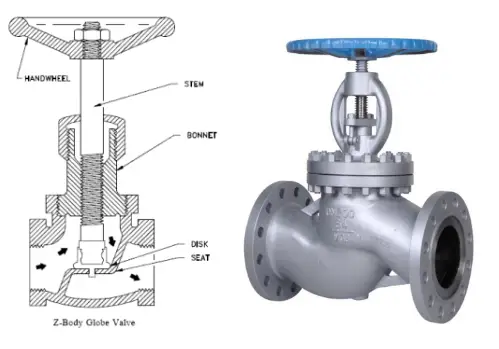

Plug valves have all the general parts such as stem, body, disc, and bonnet. It is different from other valves due to its plug disc design.

The Plug Valve Body:

The valve body has all the internal components of the valve. The body connects to the pipes through an end connection.

The Plug valve Stem:

The stem of the valve connects the disc (or disk) to the actuator. This helps in transferring the movement of the actuator to the plug disc thereby opening or closing the plug disc. The plug valve has a little stem that connects to the disc.

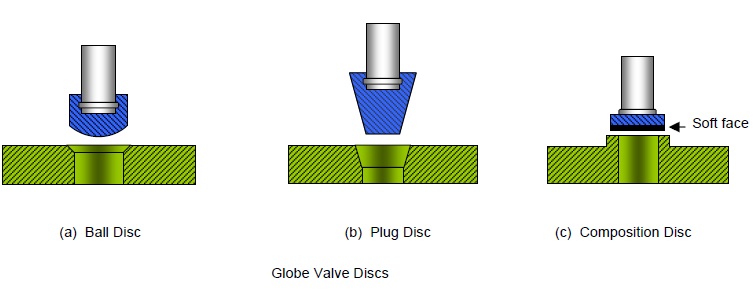

The Plug valve disc

The plug disc which is known as the tapered disc acts as a plug hence differentiating the plug valve and the globe valve. Out of all the valves, the plug valve, ball valve, and globe valve have some similarities. The major difference is in the way that how the disc looks like. The Globe valve has a cylindrical disc. The plug valve has a solid metal piece with tapered ends.

Plug Valve Ports

An important feature of a plug valve is its easy adaptation to multiport construction. In general, Multiport plug valves are used widely. They provide various benefits like:

- Simplified piping and installation

- More convenient operation than multiple gate valves.

- Elimination of costly pipe fittings.

Depending upon the number of ports in the plug valve, a multiport plug valve can eliminate four conventional shut-off valves.

Plug valves have the following port patterns:

- Round opening: It has round ports in both the plug and body.

- Rectangular opening: It has rectangular ports of the full bore section.

- Standard opening: In this, the area through the valve is less than the area of the standard pipe.

- Diamond opening: It has a diamond-shaped opening through the valve.

- Multi-port: with three or more pipe connections used for transferring services.

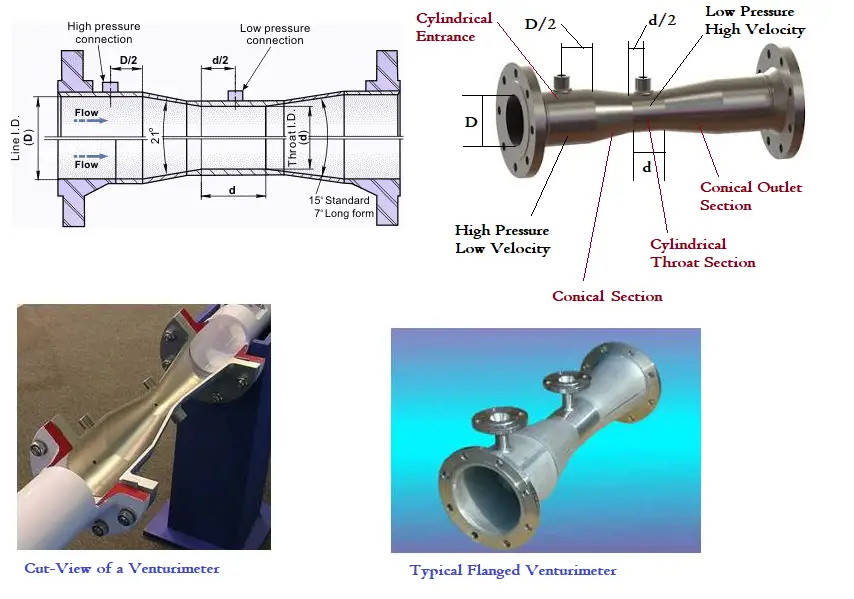

- Venturi design: It has reduced area opening with Venturi flow through the body.

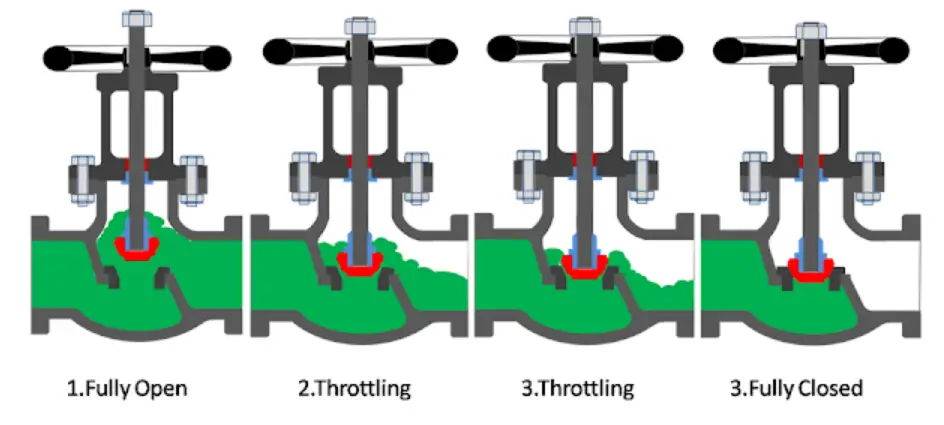

Plug Valve Working Principle

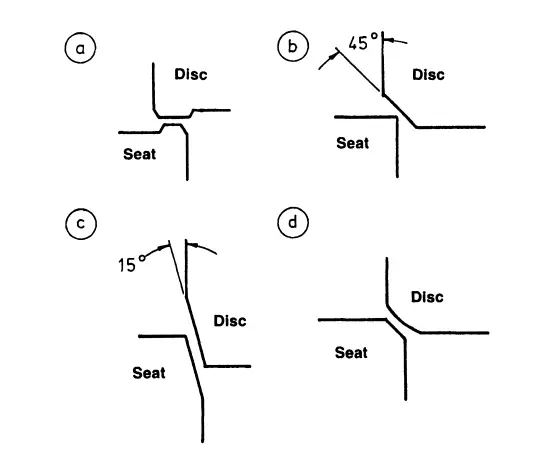

The plug valve comprises a body with tapered or parallel seating into which a plug fits. The plug is formed with a port, and the position of the port controls the amount of opening through the valve. Ports are known as the openings in the valve body through which fluid can enter or leave. A 90-degree of plug fully opens or closes the fluid flow. The plug valve is not as efficient as ball valves and can only operate fully open or closed.

When the opening in the plug is in line with the inlet and outlet ports, flow continues through the valve. A pressure drop occurs through the reduced area of the plug port. However, with a full-area cylindrical plug, the pressure drop is minimal.

When the hand operator is turned to the full quarter-turn position (90°), the plug’s opening is turned perpendicular to the flow stream, with the edges of the plug rotating through the sealing device (sleeve, lubricant, etc.). When the full quarter-turn rotation is reached, the port is completely perpendicular to the flow stream, creating a complete shutoff.

In throttling situations, where the plug is placed in a mid-turn position, the plug takes a double pressure drop. The inlet port’s flow area is reduced by turning of the plug away from the full-port position, taking a pressure drop at that point. The flow then moves into the full-port area inside the plug, where a pressure recovery takes place, followed by another restriction at the outlet port. Leakage is prevented through the seat by the compression of the plug against the sleeve or other sealing mechanism, while the packing or the collar–diaphragm assembly prevents leakage through the stem.

With three-way valve arrangements requiring diverting flow, the flow enters the inlet and moves through the plug, which channels the flow to one of the other two outlets. When the plug is moved 90°, the flow is channeled to the other outlet. At a midway position, the flow may be equally diverted to both outlets. With combining flow, flow is directed from two inlets to a single outlet. In order for some of these arrangements to occur, the plug must be turned by half-turn (180°) instead of the typical quarter-turn action.

With larger plug-valve sizes [3 in (DN 80) or larger], the torque required for seal breakout may become somewhat excessive. This is caused by the larger contact surface between the plug and sealing device as well as any adverse operating conditions, such as a high process pressure, temperature extreme, corrosion deposits, etc. In this case, hand levers are typically replaced with geared handwheels, which reduce the torque requirement significantly.

The simple plug valve is suitable for low-pressure, low-temperature applications and is made in large sizes of 250 to 300 mm. The main limitation of the plug valve is that if wide variations in fluid temperature are involved then differential expansion is inevitable, leading either to undue stiffness of operation or loss of pressure-tightness.

The plug may be tapered, or parallel and the movement may be plain or lubricated. Another variation is known as the ball plug valve, in which the plug is spherical, having circular ports rotating between circular seats of the concave section.

Types of Plug Valves / Plug Valve Types

In general, there are four types of plug valves. They are:

- Lubricated Plug Valves

- Non-lubricated Plug Valves

- Eccentric Plug Valve, and

- Expanding Plug Valve

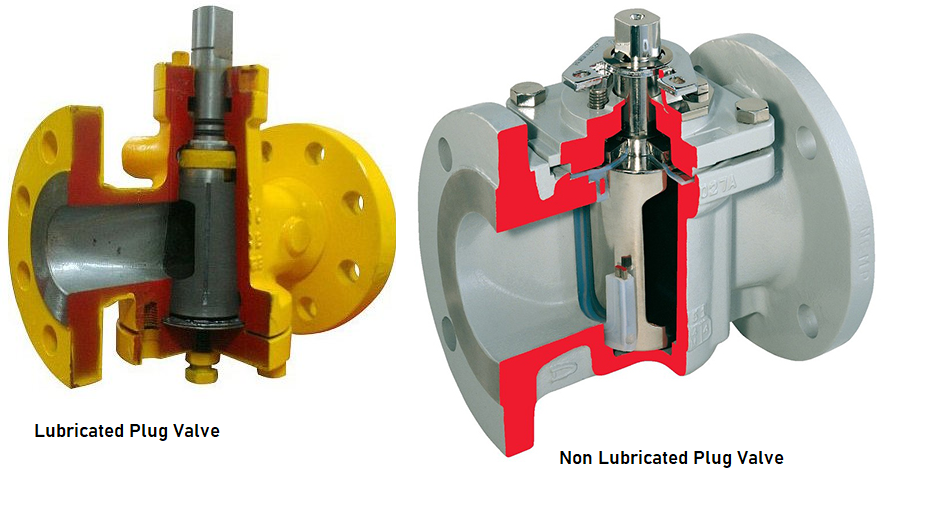

Lubricated Plug valves:

These valves use lubricants or sealants to ease their operation over a wide range of operating pressure. The lubrication film which is used between the plug and body provides a seal that requires periodic lubricant injection. The sealant must be like that it does not get washed away with the fluid as the fluid can get contaminated and it should be able to withstand line temperature. These lubricants in plug valves are mostly plastic sealants. The use of an effective sealant with properties such as proper elasticity, resistance to chemicals, and its ability to form an impervious seal around each body part is essential. The lubricating film also protects the metal surfaces between the plug and the body from corrosion.

Lubricated plug valves are manufactured in sizes ranging from DN 15 to DN 900. They are used in applications with pressures over 2500 psi.

Non-Lubricated plug valves:

These plug valves are usually used for lower-pressure lines. These valves contain an elastomeric body liner or sleeve installed in the body cavity. The plug that is tapered and polished acts like a wedge and tends to press the sleeve against the body. Thus the sleeve reduces the friction between the plug and the body.

There are three types of non-lubricated plug valves:

- Lift-type plug valve

- Elastomer-sleeved plug valve

- Fully lined plug valve

Lift type plug valve provides a mechanical lifting arrangement to disengage the tapered plug from the seating surface to permit easy rotation. The lifting can be achieved by an external lever.

The elastomer-sleeved plug valve has an elastomer sleeve. It is a TFFE sleeve that surrounds the plug completely. The elastomer sleeve is engaged and locked in place through a metal body. This sleeve has less coefficient of friction and is also self-lubricated.

Fully lined plug valve: These types of valves use inexpensive ductile iron or cast iron body. The body and plug of the valve are fully lined with Teflon in a way giving the valve the ability to resist corrosive fluids using iron as the body material.

Eccentric Plug Valve

This type of plug valve design uses a half plug. This design helps in applications requiring a higher seating force with minimal friction from the open to the closed position. Improved shut-off capabilities are the main feature of the torque seated valves. Eccentric plug valves find application in a wide range of flow control and isolation services. Some of the typical applications of eccentric plug valves are clean and dirty water, sewage, sludge and slurries, air, and other services.

Expanding Plug Valve

Expanding plug valves are complex in design. They use multiple components allowing the plug valve to expand mechanically and give it a true double block and bleed function in one valve. This type of plug valve uses a mechanism that rotates between the open and closed positions and protects both seals from the flow path. The body and seals do not contact each other during rotation which avoids wear or abrasion to the seals. For applications not requiring double isolation, expanding plug valves are often used to prevent product contamination.

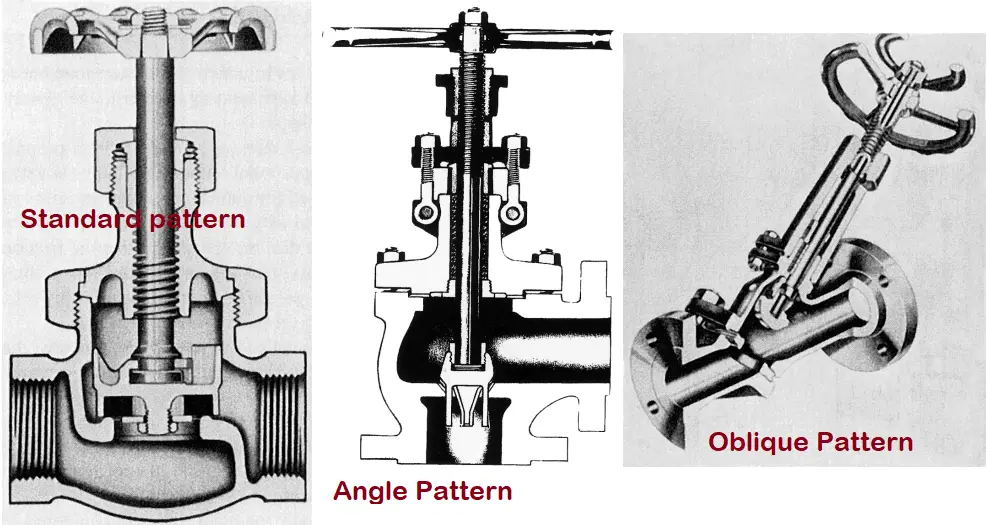

Plug Valve types by Pattern

Based on patterns, plug valves are categorized as follows:

- Round opening- Full-bore round ports in both plug and body.

- Rectangular opening with rectangular-shaped ports of full-bore section.

- The standard opening where the area through the valve is less than the area of the standard pipe.

- Diamond port where the opening through the valve is diamond-shaped.

- Multiport with three or more pipe connections.

- Venturi design with reduced area porting and featuring venturi flow through the body.

- Short plug valves with reduced area ports and reduced face-to-face dimensions.

- Vertical plug valves with reduced area seating ports and the plug passages reduced in section to form a throat.

Plug Valve Materials

Plug valves can be produced from a variety of materials; both metallic and plastic. The most common plug valve materials are

- Steel

- Stainless Steel

- Bronze

- Brass

- Plastic, etc

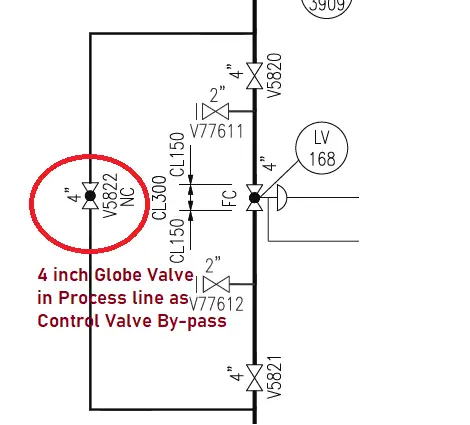

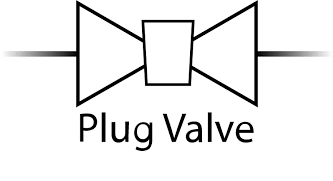

Plug Valve Symbol

In P&ID the following plug valve symbol is used for identification and differentiating from other valves.

Pressure Balanced Taper Plug Valves

In larger taper-plug valves, pressure-balanced plugs are fitted for very high static pressure applications. With a non-pressure balanced plug, line pressure in an open valve can find its way into the larger end chamber that exists below the plug. This creates a resultant force that tends to push the plug into its tapered seat causing a danger of taper locking.

With a pressure-balanced plug valve, the live line pressure replaces the sealant pressure by allowing the line to pressurize the small end chamber. A balancing force is generated which prevents the taper lock.

The pressure-balanced system consists of two holes in the plug connecting chambers at each end of the plug with the line pressure. The hole in the small end of the plug contains a non-return valve. This enables sealant pressure to be built up if necessary while allowing access to the line pressure to the small end chamber. Thus the pressure in the large end chamber always equals the line pressure and the pressure in the small end chamber is always equal to or greater than the line pressure which prevents the taper locking.

Advantages of plug valve

The main advantages of a plug valve are:

- It has a simple design and fewer parts

- It can be quickly opened or close.

- This valve offers minimal resistance to flow.

- The use of multi-port designs helps in reducing the number of valves needed and permits a change in the flow direction.

- It provides a reliable leak-tight service.

- They are easy to clean and can be done without removing the body from the piping system.

Disadvantages of plug valve

The limitations or drawbacks of a plug valve are:

- As a large amount of friction is required to rotate the plug, which results in greater force to operate these valves.

- Actuators are required for larger valves.

- These plug valves cost more than ball valves which have a similar design.

- Pressure drop is more due to reducing port.

Codes and Standards for Plug Valve Design

The industry codes and standards governing the plug valve design, test, and inspection are:

- ASME B16.10-Face-to-Face and End-to-End Valve Dimensions

- API 599 – Metal Plug Valves – Flanged, Threaded, and Welding Ends

- API 6D – Specification for Pipeline valves

- API 598 – Valve Inspection and Testing

- API 6FA – Fire Test for Valves

- BS 5353 – Specification for steel plug valves

- BS 5188 – Specification for cast iron plug valves

- MSS SP 61 – Pressure testing of steel valves

- MSS SP 25 – Standard marking system for valves, fittings, flanges & unions

- MSS SP 78- Gray Iron Plug Valves, Flanged and Threaded Ends

Applications of Plug Valves

As stated earlier, Plug valves are suitable for a wide range of services like Air, gas, vapor, slurry, mineral ore, sewage applications, oil piping systems, etc. They are suitable for vacuum as well as high-pressure applications even though Plug valves are usually used in low-pressure-low-temperature services. The majority of plug valves are used:

- for directional flow control, even in moderate vacuum systems.

- for efficient handling of gas and liquid fuel.

- for safe handling of extreme temperature flow, such as boiler feed water, condensate, and other such elements.

- to regulate the flow of liquids containing suspended solids like slurries.

Plug Valve vs Ball Valve

Even though both the Plug valve and the Ball valve are quarter-turn rotary valves, they have few dis-similarities. The major differences between a plug valve and a ball valve; i.e, Plug valve vs Ball valve are listed below:

| Plug Valve | Ball Valve |

| The disk of a plug valve is cylindrical or conical | The disk shape in a ball valve is spherical |

| The disk size in the plug valve is comparatively larger. | The disk size is smaller. |

| The Sealing surface is larger in plug valves. | The Sealing surface is comparatively smaller in ball valves. |

| More torque requirement for plug valve operation. So, limited application of bigger size plug valves | Ball valves provide torque-free operation and are suitable for all sizes. |

| Plug valves are heavier as compared to ball valves of the same size and rating. | Lighter in weight. |

| Ease of maintenance. | Difficulty maintenance. |

| The lifespan of plug valves is normally less than ball valves | More lifespan. |

| The cost of the plug valve is less. | Comparatively expensive as compared to plug valves. |

| Plug valves are full port, thus allowing full flow. | Ball valves are available in full and reduced ports. |

| Construction is simple. | Ball valve construction is complex. |

| Plug valves provide better flow control as compared to ball valves. |